Preparation method for flexible soft monomer colloid photonic crystal emulsion

A technology of colloidal photonic crystals and soft monomers, applied in the field of preparation of flexible soft monomer colloidal photonic crystal emulsions, can solve the problems of insufficient elasticity and toughness of materials, high glass transition temperature of homopolymers, etc., and achieve convenient operation, simple equipment, Superior effect of monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

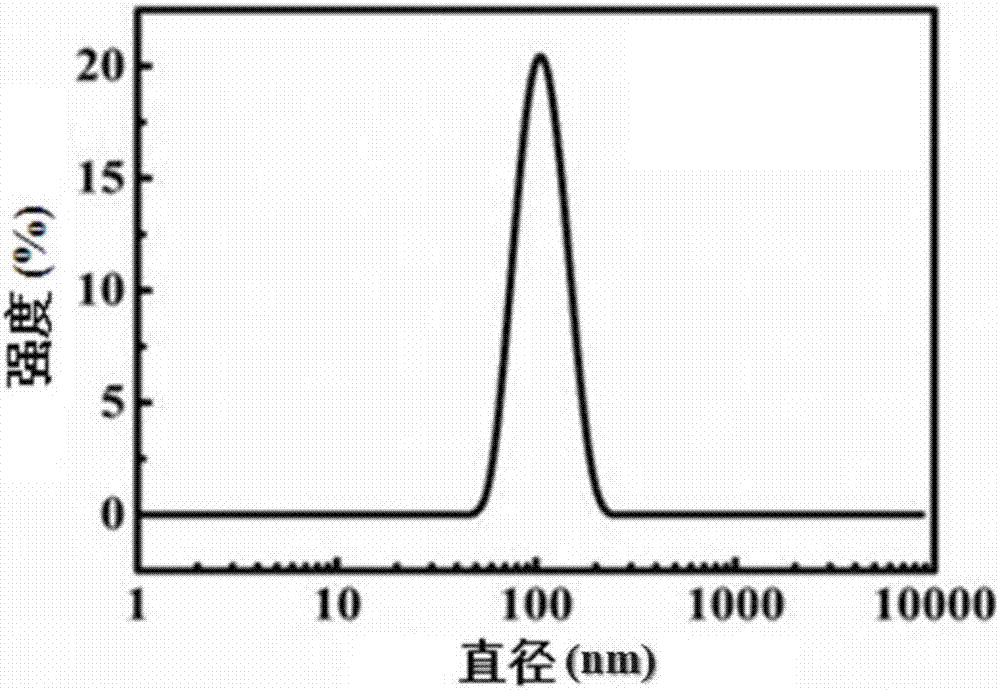

[0027] Weigh 0.01g of cross-linking agent N,N-methylenebisacrylamide and 90g of deionized water into a 250mL four-necked bottle, then add 2.0g of tertiary acrylic acid after washing and refining with 10% potassium hydroxide aqueous solution Butyl ester monomer and pass through stable nitrogen. Stir mechanically at 25°C at a speed of 180rmp for 25min, then heat up to 80°C, and then dropwise add 0.036g of initiator potassium persulfate dissolved in 10mL of water to initiate polymerization. After the reaction is finished, cool to room temperature, and then filter with a 200-mesh gauze to remove a small amount of gel to obtain a monodisperse poly(tert-butyl acrylate) colloidal emulsion. according to figure 1 The particle size distribution diagram shows that poly tert-butyl acrylate colloid particle size is about 103nm, and the monodispersity index of the emulsion is only 3.3%.

Embodiment 2

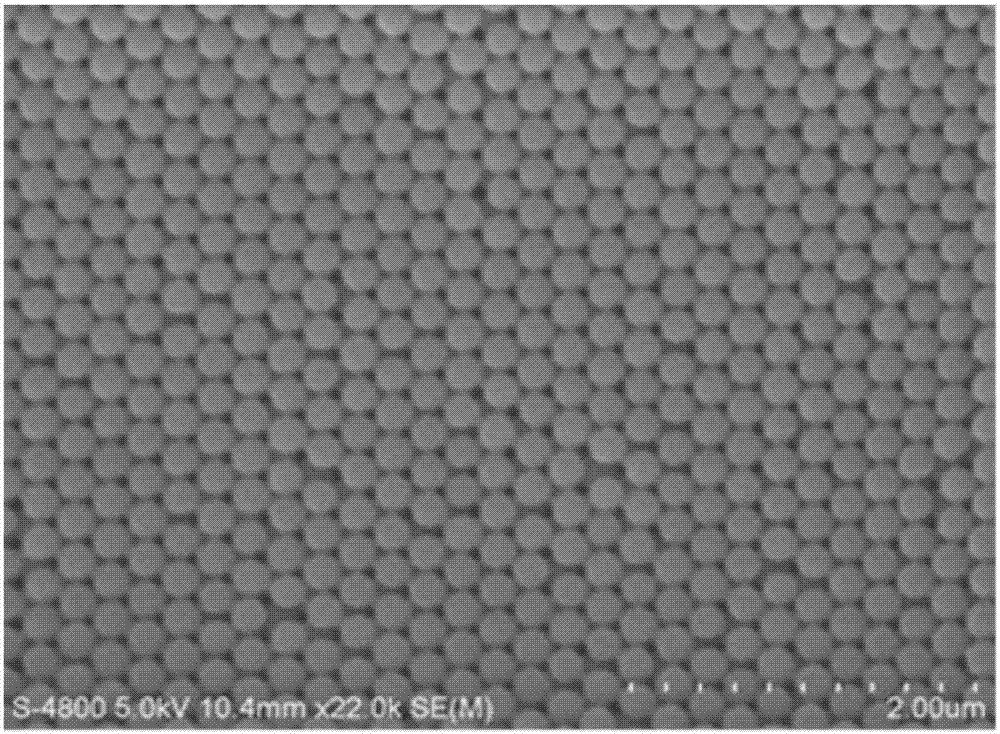

[0029] Weigh 0.008g of cross-linking agent methylol acrylamide and 90mL of deionized water into a 250mL four-necked bottle with a balance, then add 3.52g of tert-butyl acrylate monomer after washing and refining with 5% aqueous sodium hydroxide solution and Introduce stable argon gas, mechanically stir at 25°C at a speed of 200rmp for 30min, then heat up to 98°C, then dropwise add initiator dissolved in 10mL of water per 0.04g of ammonium persulfate to initiate polymerization. After the reaction is finished, cool to room temperature, and then filter with a 200-mesh gauze to remove a small amount of gel to obtain a monodisperse poly(tert-butyl acrylate) colloidal emulsion. figure 2 It is the SEM image of tert-butyl polyacrylate, the particle size is about 191nm, and the closely arranged structure of colloidal microspheres of tert-butyl acrylate shows that it has excellent monodispersity performance. The colloidal emulsion of tert-butyl acrylate is centrifuged and concentrated ...

Embodiment 3

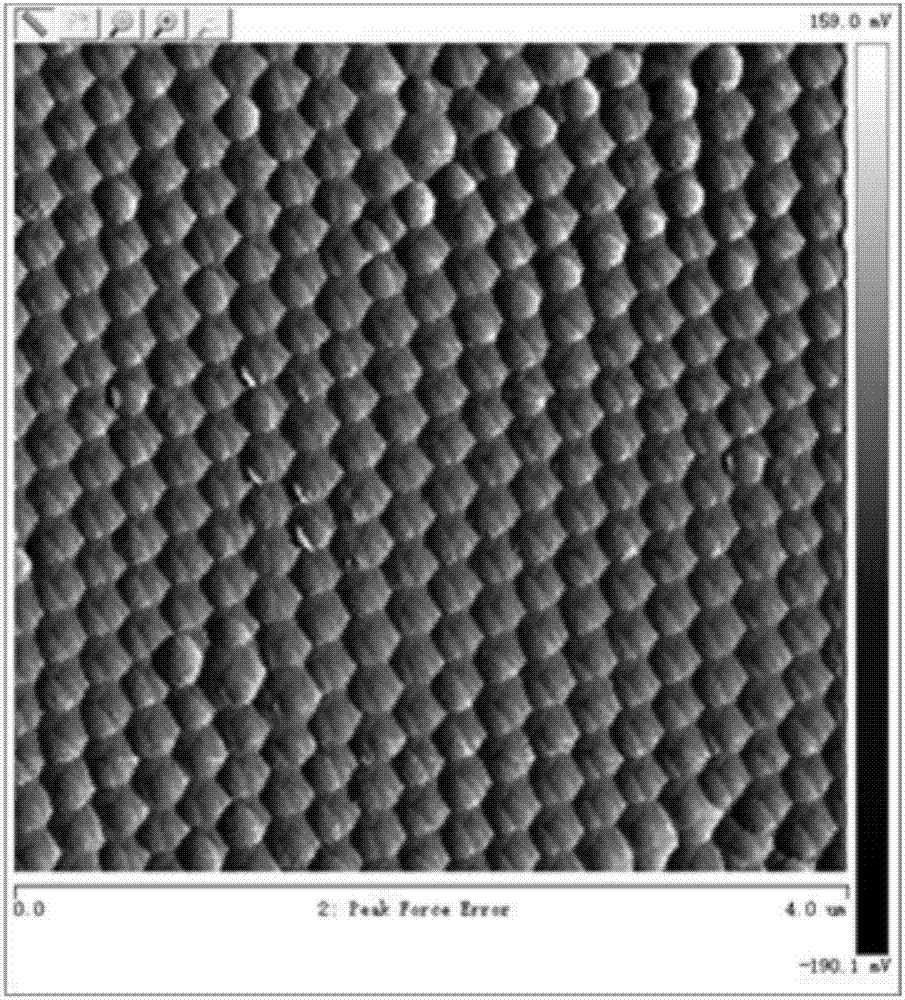

[0031] Weigh 0.006g of cross-linking agent methylol acrylamide and 90mL of deionized water into a 250mL four-necked bottle with a balance, then add 4.16g of tert-butyl acrylate monomer after washing and refining with 5% aqueous sodium hydroxide solution and Introduce stable argon gas, mechanically stir at 25°C at a speed of 200rmp for 40min, then heat up to 85°C, then dropwise add initiator dissolved in 10mL of water per 0.04g of ammonium persulfate to initiate polymerization. After the reaction is finished, cool to room temperature, and then filter with a 200-mesh gauze to remove a small amount of gel to obtain a monodisperse poly(tert-butyl acrylate) colloidal emulsion. image 3 It is the AFM diagram of poly-tert-butyl acrylate, the particle size is about 244nm, and the structure of closely packed colloidal particles of poly-tert-butyl acrylate shows that it has excellent monodispersity performance. The colloidal emulsion of poly-tert-butyl acrylate is centrifuged and concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com