Super capacitor electrode material Zn doping NiCo2O4 compound and preparation method

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes, nanotechnology, etc., can solve the problems that electrode materials need to be further improved, and achieve the effects of improving electrochemical performance, easy process control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

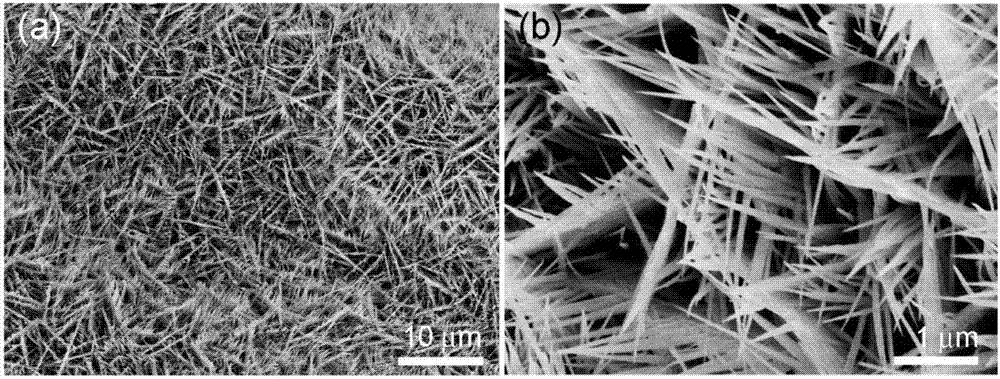

Image

Examples

Embodiment 1

[0023] 1) Weigh 1mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 2mmol cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 0.75mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 10mmol ammonium fluoride (NH 4 F) and 15mmol of urea, dissolved in 50mL of water, and fully stirred to obtain a mixed solution.

[0024] 2) Pour the mixed solution obtained in step 1) into a polytetrafluoroethylene hydrothermal reaction kettle and put a piece of cleaned foamed nickel, put the reaction kettle into a blast drying oven, and react under 120°C hydrothermal conditions for 12 Hours, after the reaction, the reactor was cooled to room temperature, and the nickel foam with the precursor was taken out, washed with deionized water and ethanol respectively, and dried.

[0025] 3) Calcining the nickel foam with the precursor in the muffle furnace, the calcination temperature is 300°C, and the time is 2 hours, the precursor attached to the foam nickel is converted into Zn-doped NiCo b...

Embodiment 2

[0027] 1) Weigh 1mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 2mmol cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 0.1mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 5mmol ammonium fluoride (NH 4 F) and 30mmol of urea were dissolved in 50mL of water, and fully stirred to obtain a mixed solution.

[0028] 2) Pour the mixed solution obtained in step 1) into a polytetrafluoroethylene hydrothermal reaction kettle and put a piece of cleaned carbon cloth, put the reaction kettle into a blast drying oven, and react under 150°C hydrothermal conditions for 3 Hours, after the reaction, the reactor was cooled to room temperature, and the nickel foam with the precursor was taken out, washed with deionized water and ethanol respectively, and dried.

[0029] 3) Calcining the nickel foam with the precursor in the muffle furnace, the calcination temperature is 450 °C, and the time is 2 hours, the precursor attached to the foam nickel is converted into Zn-doped NiCo ...

Embodiment 3

[0031] 1) Weigh 1mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 2mmol cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 1mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 20mmol ammonium fluoride (NH 4 F) and 5mmol of urea were dissolved in 50mL of water, and fully stirred to obtain a mixed solution.

[0032] 2) Pour the mixed solution obtained in step 1) into a polytetrafluoroethylene hydrothermal reaction kettle and put a piece of cleaned carbon fiber paper, put the reaction kettle into a blast drying oven, and react for 20 Hours, after the reaction, the reactor was cooled to room temperature, and the nickel foam with the precursor was taken out, washed with deionized water and ethanol respectively, and dried.

[0033] 3) Calcining the nickel foam with the precursor in the muffle furnace, the calcination temperature is 250 ° C, and the time is 10 hours, the precursor attached to the foam nickel is converted into Zn-doped NiCo by calcination 2 o 4 Comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com