Phosphor-doped silicon-graphite composite material, negative electrode material comprising same and lithium ion battery

A composite material and phosphorus doping technology, which is applied in the field of lithium-ion battery energy, can solve the problems of inapplicability to mass production, poor conductivity of silicon, and high cost, and achieve excellent cycle performance, improved conductivity, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

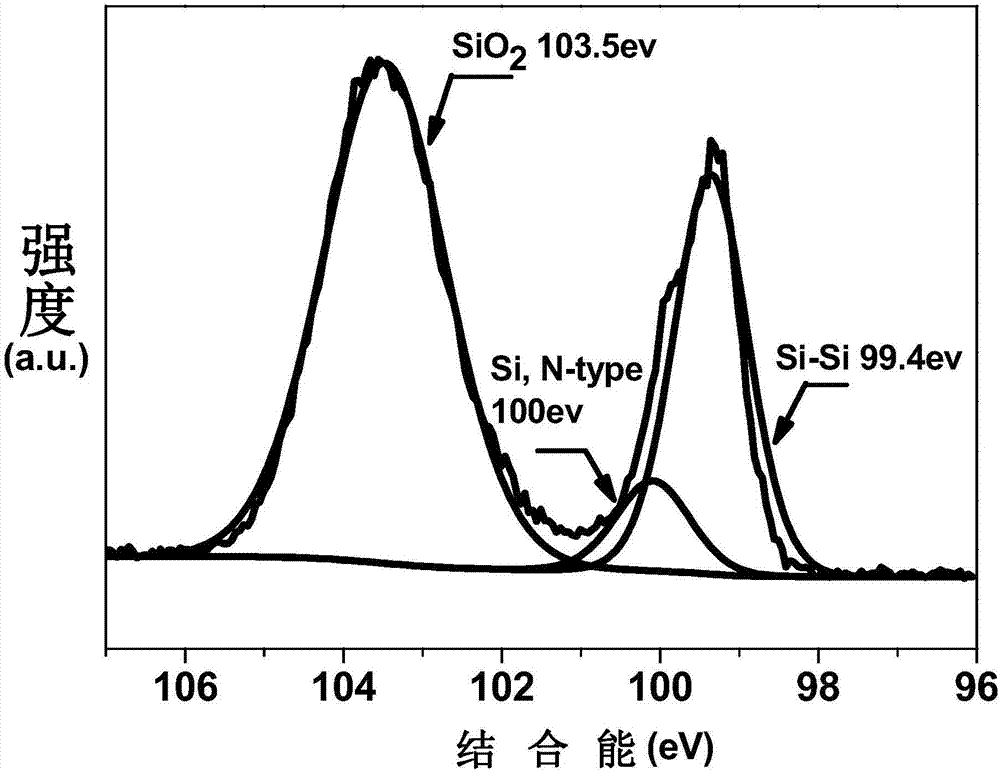

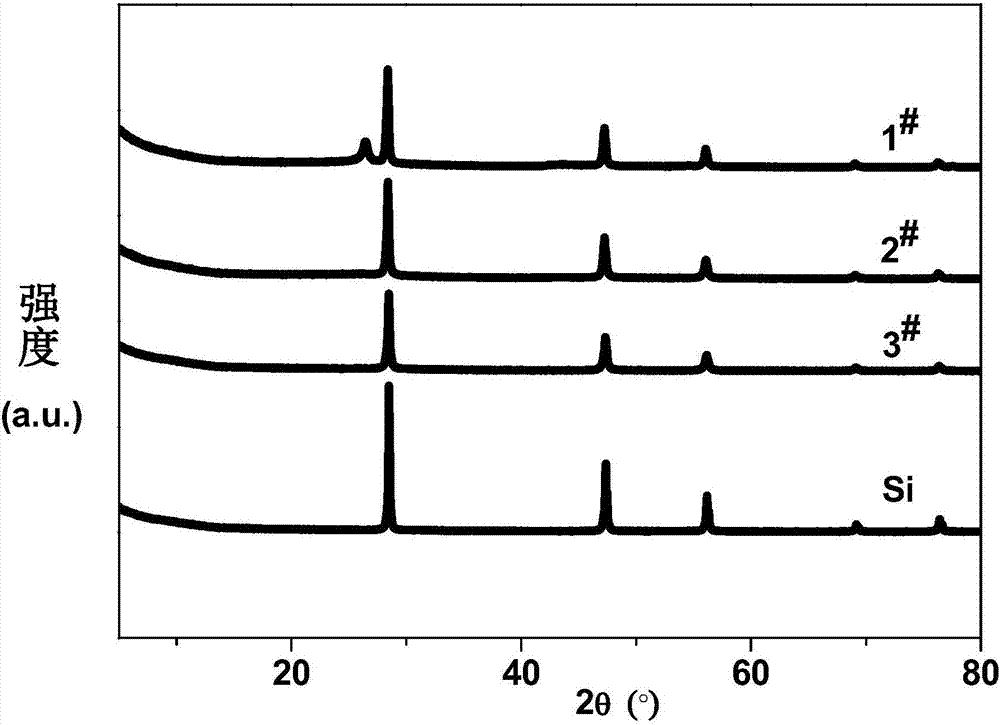

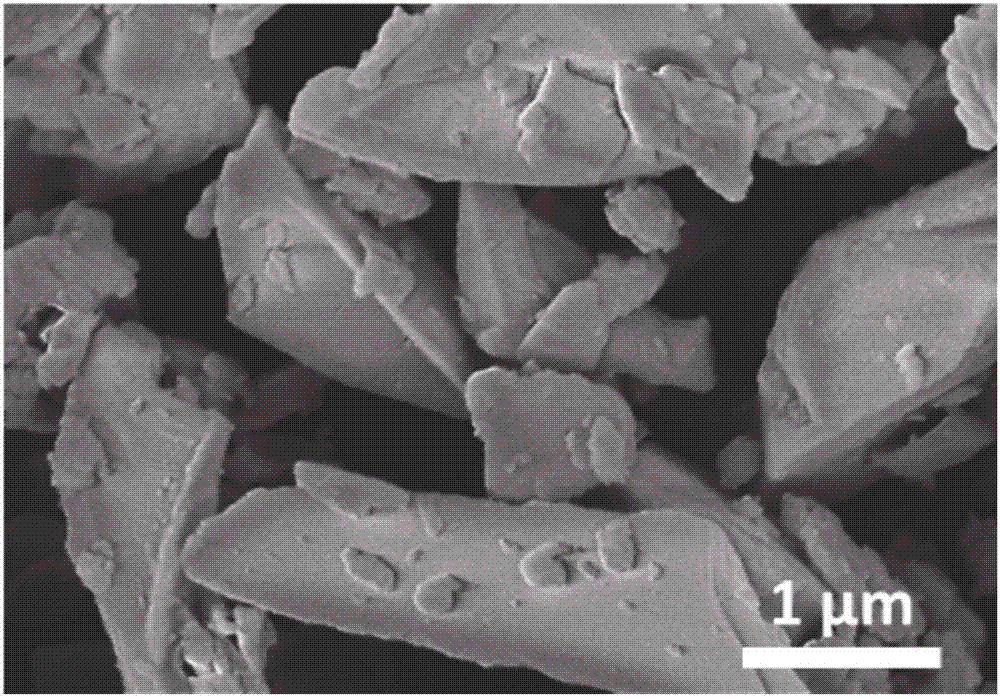

[0059] sample 1 # Preparation of:

[0060] The crystalline silicon powder with a purity of 99.9%, the particle size of 1-3 μm, and the red phosphorus powder with a purity of 98.5% are ball milled in the first step under the protection of argon; the mass of the crystalline silicon powder accounts for 99% of the total mass of the powder, The rotational speed of the ball mill was 350 rpm, the ball milling time was 6 hours, and the mass ratio of the stainless steel ball milling beads to the powder was 20:1 to obtain phosphorus-doped silicon powder.

[0061] The phosphorus-doped silicon powder obtained above and the graphite powder with a purity of 99.95% and a size of 8000 mesh were subjected to a second ball milling step under the protection of argon. The graphite powder mass accounts for 70% of the total powder mass, the ball mill speed is 400rpm, the ball milling time is 12h, and the mass ratio of stainless steel ball milling beads to powder is 20:1 to obtain a phosphorus-do...

Embodiment 2

[0066] sample 2 # Preparation of:

[0067] The crystalline silicon powder with a purity of 99.9%, the particle size of 1-3 μm, and the red phosphorus powder with a purity of 98.5% are ball milled in the first step under the protection of argon; the mass of the crystalline silicon powder accounts for 99% of the total mass of the powder, The rotational speed of the ball mill was 350 rpm, the ball milling time was 6 hours, and the mass ratio of the stainless steel ball milling beads to the powder was 20:1 to obtain phosphorus-doped silicon powder.

[0068] The phosphorus-doped silicon powder obtained above and the graphite powder with a purity of 99.95% and a size of 8000 mesh were subjected to a second ball milling step under the protection of argon. The graphite powder mass accounts for 50% of the total powder mass, the ball mill speed is 400rpm, the ball milling time is 12h, the mass ratio of stainless steel ball milling beads to powder is 20:1, and phosphorus doped silicon...

Embodiment 3

[0073] sample 3 # Preparation of:

[0074] The crystalline silicon powder with a purity of 99.9%, the particle size of 1-3 μm, and the red phosphorus powder with a purity of 98.5% are ball milled in the first step under the protection of argon; the mass of the crystalline silicon powder accounts for 99% of the total mass of the powder, , the rotational speed of the ball mill is 350rpm, the ball milling time is 6h, the mass ratio of stainless steel ball milling beads to powder is 20:1, and phosphorus-doped silicon powder is obtained.

[0075] The phosphorus-doped silicon powder obtained above and the graphite powder with a purity of 99.95% and a size of 8000 mesh were subjected to a second ball milling step under the protection of argon. The graphite powder mass accounts for 30% of the total powder mass, the ball mill speed is 400rpm, the ball milling time is 12h, the mass ratio of stainless steel ball milling beads to powder is 20:1, and phosphorus-doped silicon-graphite co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com