High-temperature-resistant deodorizing and nitrogen preserving fermented organic manure strain and preparation method thereof

A technology of fermenting bacterial agent and organic fertilizer, which is applied in the field of preparation of high-temperature resistant deodorizing and nitrogen-preserving organic fertilizer fermenting bacterial agent, can solve problems such as rapid deodorization and nitrogen-retaining deficiency, achieve good ecological and economic benefits, and improve microbial efficiency. Adsorption rate, the effect of improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

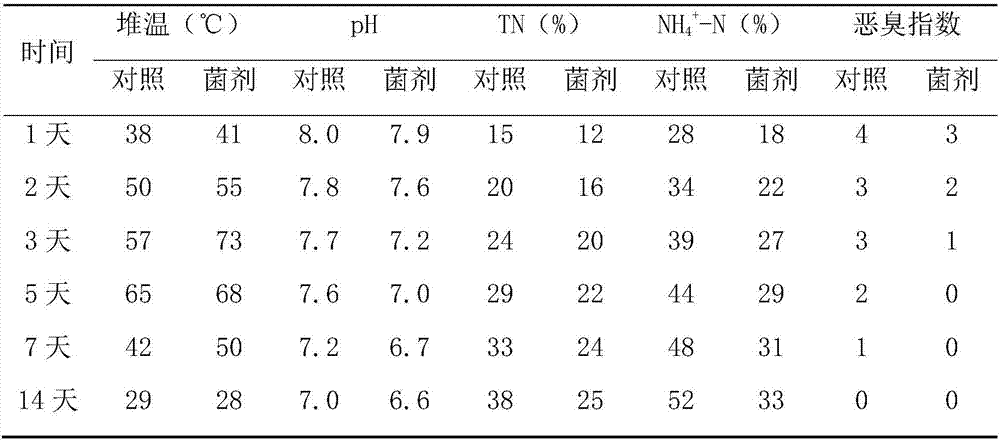

Image

Examples

Embodiment 1

[0022] Carry out the preparation of fermentation bacterial agent according to the following steps:

[0023]1. Perform activation treatment on the slant strains stored in the refrigerator at 4°C, Bacillus subtilis CGMCC1.775, Actinomucor elegans CGMCC3.4389, Bacilus cereus CGMCC1.230, Bacillus licheniformis Seven strains of licheniformis CGMCC1.7461, Rhodopseudomonas CGMCC1.5007, Lactococcus lactisCGMCC1.2281, and Saccharomyces cerevisiae CGMCC2.1643 were cultured in test tube-shaker respectively to obtain first-grade seeds of each strain liquid.

[0024] Bacillus subtilis CGMCC1.775, Bacillus cereusCGMCC1.230 and Rhodopseudomonas CGMCC1.5007 were cultured with beef extract peptone medium: 3g beef extract, 10g peptone, 5g sodium chloride, distilled water 1000mL, adjust the pH value to 7.0; the inoculum size is 1%, 200rpm, and cultivate for 24h.

[0025] Actinomucor elegans CGMCC3.4389 and Saccharomycescerevisiae CGMCC2.1643 were cultured in potato-sucrose medium: take 200 gra...

Embodiment 2

[0033] 1. Activate the seven doses of slant strains stored in the refrigerator at 4°C, Bacillus subtilis CGMCC1.775, Actinomucor elegans CGMCC3.4389, Bacilus cereus CGMCC1.230, Bacillus licheniformis Bacillus licheniformis CGMCC1.7461, Rhodopseudomonas CGMCC1.5007, Lactococcus lactisCGMCC1.2281, and Saccharomyces cerevisiae CGMCC2.1643 were cultured in test tubes and shakers respectively to obtain first-grade seed solutions of each strain.

[0034] Bacillus subtilis CGMCC1.775, Bacillus cereusCGMCC1.230 and Rhodopseudomonas CGMCC1.5007 were cultured with beef extract peptone medium: 3g beef extract, 10g peptone, 5g sodium chloride, distilled water 1000mL, adjust the pH value to 7.2; the inoculum size is 1.5%, 220rpm, culture for 27h.

[0035] Actinomucor elegans CGMCC3.4389 and Saccharomycescerevisiae CGMCC2.1643 were cultivated in potato-sucrose medium: take 200 grams of peeled potatoes, cut them into small pieces, add 1000 mL of water and boil for 30 minutes, filter out pota...

Embodiment 3

[0043] 1. Activate the seven doses of slant strains stored in the refrigerator at 4°C, Bacillus subtilis CGMCC1.775, Actinomucor elegans CGMCC3.4389, Bacilus cereus CGMCC1.230, Bacillus licheniformis Bacillus licheniformis CGMCC1.7461, Rhodopseudomonas CGMCC1.5007, Lactococcus lactisCGMCC1.2281, and Saccharomyces cerevisiae CGMCC2.1643 were cultured in test tubes and shakers respectively to obtain first-grade seed solutions of each strain.

[0044] Bacillus subtilis CGMCC1.775, Bacillus cereusCGMCC1.230 and Rhodopseudomonas CGMCC1.5007 were cultured with beef extract peptone medium: 3g beef extract, 10g peptone, 5g sodium chloride, distilled water 1000mL, adjust the pH value to 7.4; the inoculum size is 2%, 250rpm, and cultivate for 30h.

[0045] Actinomucor elegans CGMCC3.4389 and Saccharomycescerevisiae CGMCC2.1643 were cultivated in potato-sucrose medium: take 200 grams of peeled potatoes, cut them into small pieces, add 1000 mL of water and boil for 30 minutes, filter out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com