Environment-friendly nano material for automobile tail gas nitric oxide catalysis purification and preparation method of environment-friendly nano material

A nitrogen oxide, catalytic purification technology, applied in the direction of nanotechnology for materials and surface science, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of easy particle agglomeration and productivity Low cost, high preparation cost, etc., to achieve the effect of low preparation cost, simple preparation, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

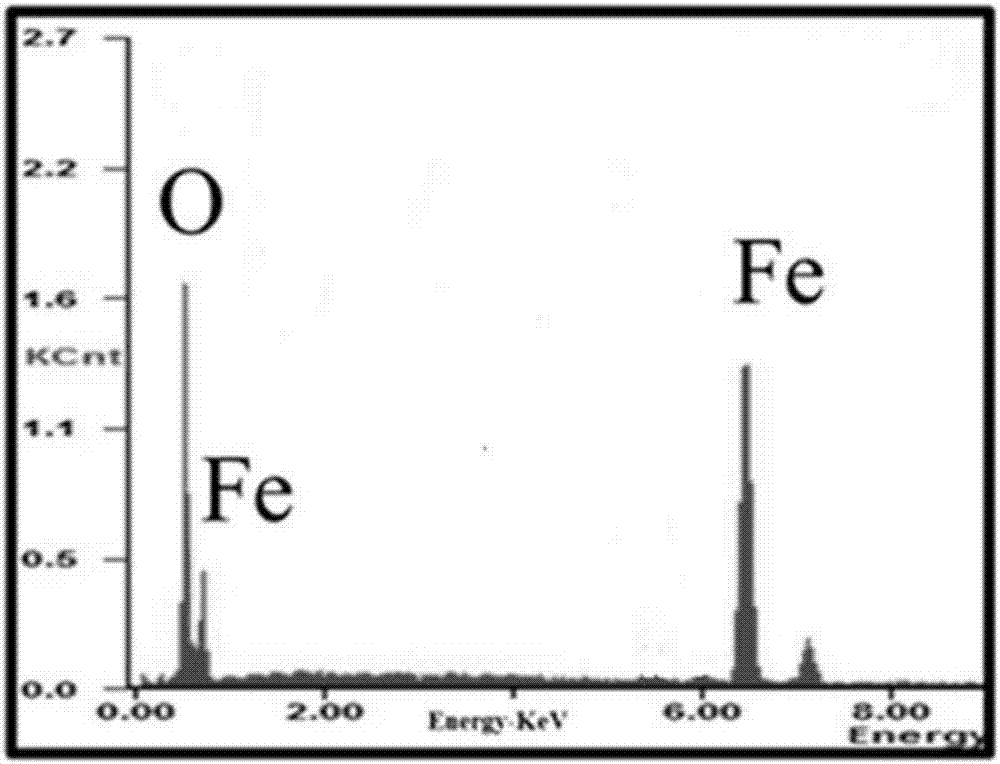

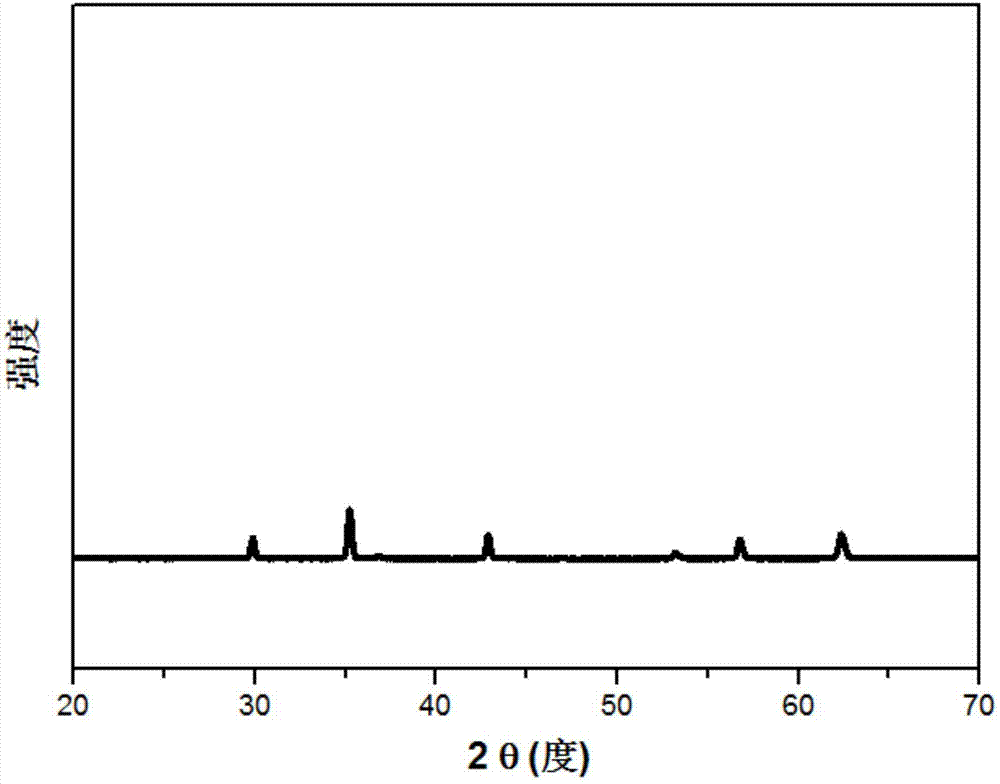

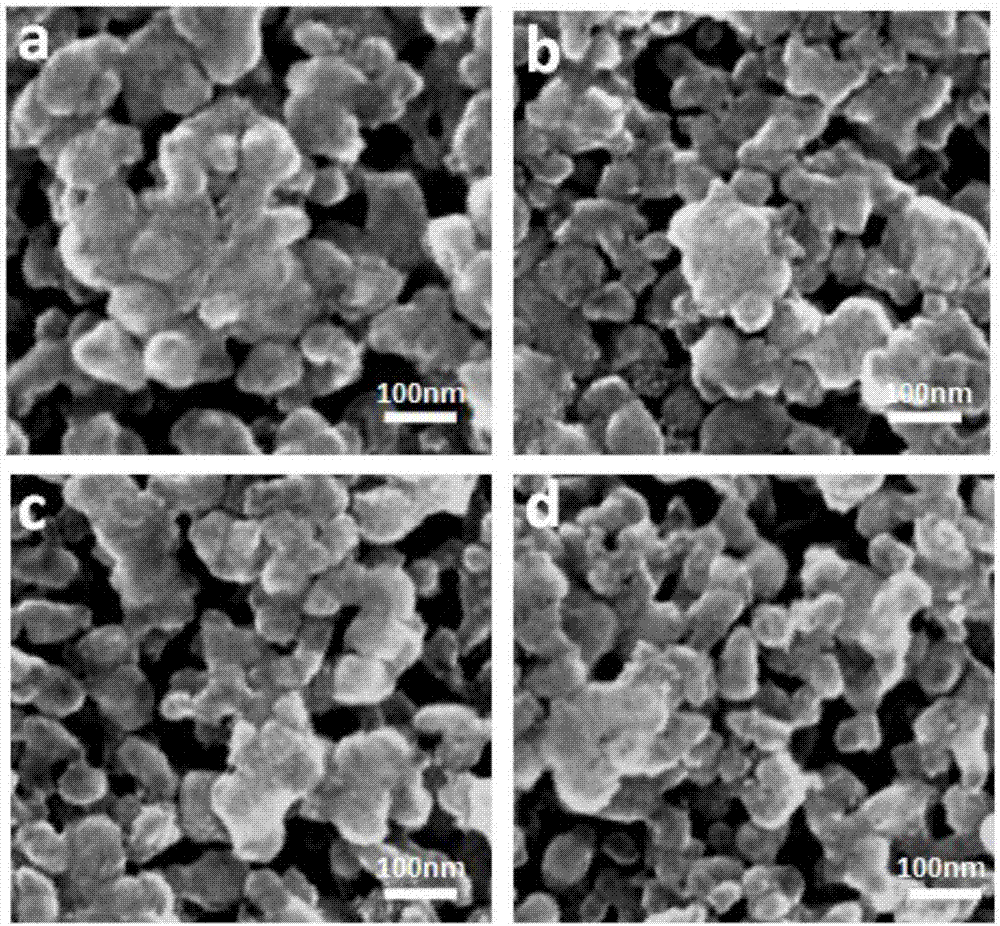

[0022] Embodiment 1: environmental protection nano material γ-Fe 2 o 3 Preparation of:

[0023] (1) Wipe the surface of the iron wire (0.5 mm in diameter, 4.5 grams in mass) with emery paper and alcohol cotton to remove oxides on the surface and make the surface smooth and clean;

[0024] (2) Put the iron wire (cut into 2cm long pieces) into 80mL mixed solution, the mixed solution is composed of 5mL absolute ethanol and 44.8g KOH, and the rest is deionized water;

[0025] (3) Put the iron wire and the mixed solution together into a polytetrafluoroethylene-lined reactor, and react at 270°C for 36 hours;

[0026] (4) Take out the reaction kettle and cool it to room temperature, then ultrasonicate the reaction system for 9 hours, then filter the ultrasonic product to remove unreacted iron wire; the particles obtained by filtering are soaked and stirred in an ammonia solution with a mass fraction of 10% After 2 hours, soak and stir in 5% hydrochloric acid aqueous solution for 1...

Embodiment 2

[0030] Embodiment 2: environmental protection nano material γ-Fe 2 o 3 Preparation of:

[0031] (1) Wipe the surface of the iron wire (2.8 mm in diameter, 5 grams in mass) with emery paper and alcohol cotton to remove oxides on the surface and make the surface smooth and clean;

[0032] (2) Put the iron wire (cut into 2cm long pieces) into 80mL mixed solution, the mixed solution is composed of 10mL absolute ethanol and 44.8g KOH, and the rest is deionized water;

[0033] (3) Put the iron wire and the mixed solution together into a polytetrafluoroethylene-lined reaction kettle, and react at 270°C for 24 hours;

[0034] (4) Take out the reaction kettle and cool it to room temperature, then ultrasonicate the reaction system for 10 hours, then filter the ultrasonic product to remove the unreacted iron wire; the particles obtained by filtering are soaked and stirred in an ammonia solution with a mass fraction of 10% After 2 hours, soak and stir in 4% hydrochloric acid aqueous so...

Embodiment 3

[0038] Embodiment 3: environmental protection nano material γ-Fe 2 o 3 Preparation of:

[0039] (1) Wipe the surface of the iron wire (0.5 mm in diameter, 6 grams in quality) with emery paper and alcohol cotton to remove oxides on the surface and make the surface smooth and clean;

[0040] (2) Put the iron wire (cut into 2cm long pieces) into 80mL mixed solution, the mixed solution is composed of 5mL absolute ethanol and 44.8g KOH, and the rest is deionized water;

[0041] (3) Put the iron wire and the mixed solution together into a polytetrafluoroethylene-lined reaction kettle, and react at 280°C for 36 hours;

[0042] (4) Take out the reaction kettle and cool it to room temperature, then ultrasonicate the reaction system for 15 hours, then filter the ultrasonic product to remove the unreacted iron wire; the particles obtained by filtering are soaked and stirred in an ammonia solution with a mass fraction of 15% After 2 hours, soak and stir in 5% hydrochloric acid aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com