Vegetable accelerated fermentation technology

A fermentation process, a technology of inoculation fermentation, which is applied in the direction of climate change adaptation, food ingredients as taste improvers, and food ingredients as taste improvers. The effect of improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A safe and nutritious vegetable rapid fermentation process, the specific steps are as follows: put the washed cabbage leaves in a constant temperature water bath, the water temperature is 85-90°C, keep it for 0.5-1min, take it out and quickly put it into cold water for rinsing; The rinsed cabbage is placed in a sieve basket to drain the surface moisture; the cabbage leaves are cut into 3-4cm sections; the sectioned cabbage is put into sterilized glass bottles (500ml), each bottle contains 250g, and Press it tightly to remove the air; put a sterilized stone weighing about 80-100g in the bottle containing the cabbage, prepare a 2% saline solution, boil and filter, the temperature drops to room temperature, and pour the prepared saline into the glass bottle, the height should be higher than the stone pressed on the vegetables, inject 325ml into each bottle;

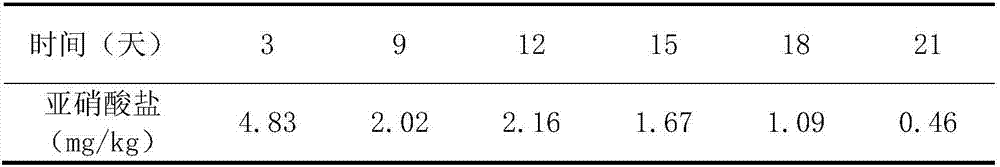

[0019] Take 10ml of the Lactobacillus casei subsp. rhamnosus mutant strain lactic acid bacteria liquid that has bee...

Embodiment 2

[0021] Put the washed cabbage leaves in a constant temperature water bath, keep the water temperature at 85°C for 1 minute, take it out and quickly rinse in cold water; put the rinsed cabbage in a sieve basket to drain the surface water; cut the cabbage leaves into 3cm sections The cabbage after sectioning is packed in the sterilized glass bottle (500ml), and every bottle capacity 250g, and compresses, gets rid of air; In the bottle that packs cabbage, put a sterilized stone, heavy 93g, prepare 2 % saline solution, boiled and filtered, the temperature dropped to room temperature, and the prepared brine was injected into glass bottles, the height of which was higher than the stone pressed on the vegetables, and 325ml was injected into each bottle.

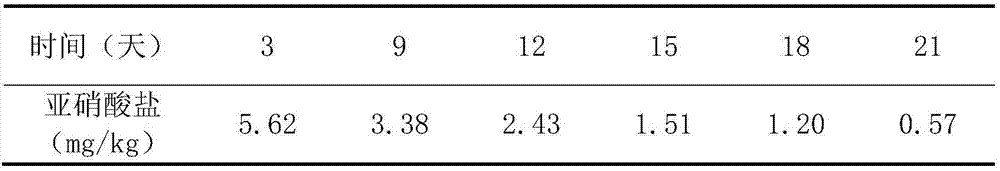

[0022] Take 10ml of the Lactobacillus casei subsp. rhamnosus mutant strain lactic acid bacteria liquid that has been cultured for 36 hours, put it into a glass bottle, shake the liquid, seal it with a sterilized bottle cap, and ferme...

Embodiment 3

[0026] Put the washed cabbage leaves in a constant temperature water bath at a temperature of 90°C and blanch for 0.5 minutes. After taking them out, put them into cold water to rinse quickly; put the rinsed cabbage in a sieve basket to drain the surface water; cut the cabbage leaves into 4cm section; the cabbage after sectioning is packed in sterilized glass bottle (500ml), and every bottle capacity is 250g, and compresses, and gets rid of air; Put a piece of sterilized stone in the bottle that packs cabbage, weighs about 85g, Prepare 2% saline solution, boil and filter, the temperature is lowered to room temperature, pour the prepared brine into glass bottles, the height can exceed the stone pressed on the vegetables, and inject 325ml into each bottle.

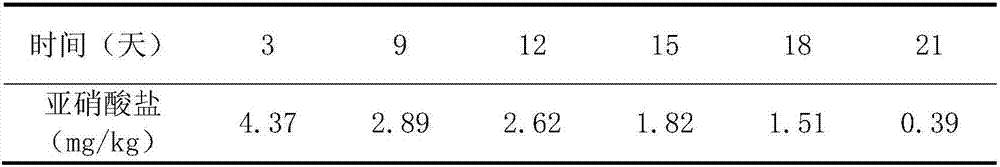

[0027] Take 10ml of the Lactobacillus casei subsp. rhamnose mutant strain lactic acid bacteria liquid that has been cultured for 36 hours, put it into a glass bottle, shake the liquid; seal it with a sterilized bottle cap; fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com