Building material and preparation method thereof

A technology for building materials and raw materials, which is applied in the field of materials to achieve the effects of good wear resistance, good mechanical properties and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

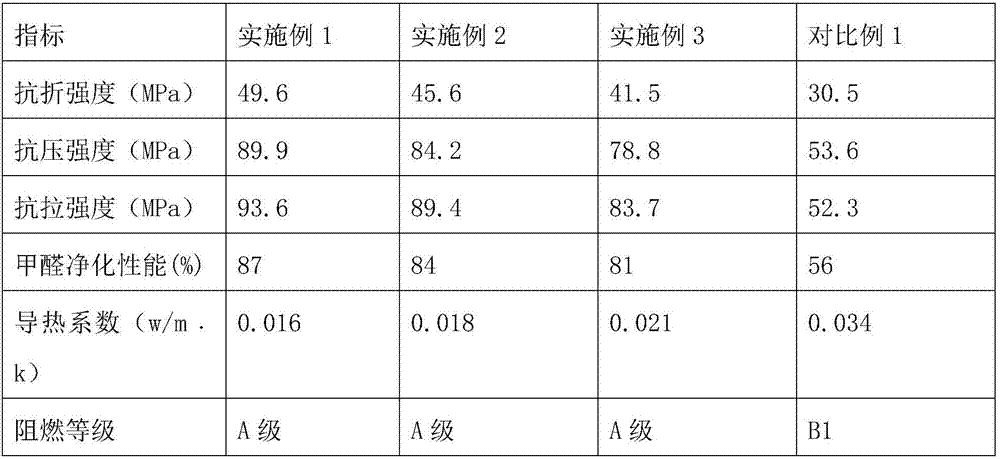

Examples

Embodiment 1

[0043] A building material, comprising the following raw materials in parts by weight: 5-9 parts of nano-titanium dioxide, 7-13 parts of asphalt, 11-15 parts of bauxite, 8-10 parts of tricalcium silicate, and 4-8 parts of polypropylene resin , 6-14 parts of phenolic resin, 8-10 parts of quartz stone powder, 13-21 parts of fly ash, 13 parts of waste polyurethane foam, 12-18 parts of nano-silicon carbide, 9-13 parts of quartz glass fiber, expanded vitrified micro 9-15 parts of beads, 7-11 parts of zircon powder, 13-17 parts of activated carbon, 13-23 parts of attapulgite, 11-21 parts of diatomite, 0.2-0.4 parts of compatibilizer, and 0.3-0.9 parts of light stabilizer 0.2-0.8 parts of antioxidant, 0.3-0.7 parts of heat stabilizer and 5-7 parts of water.

[0044] Fly ash and waste polyurethane foam are added to the raw materials, and flue ash and waste polyurethane foam are used as industrial waste and construction waste, which have been left in the city for a long time or burned ...

Embodiment 2

[0063] A building material comprising the following raw materials in parts by weight: 5 parts of nano-titanium dioxide, 7 parts of asphalt, 11 parts of bauxite, 8 parts of tricalcium silicate, 4 parts of polypropylene resin, 6 parts of phenolic resin, and 8 parts of quartz stone powder , 13 parts of fly ash, 11 parts of waste polyurethane foam, 12 parts of nano-silicon carbide, 9 parts of quartz glass fiber, 9 parts of expanded vitrified microspheres, 7 parts of zircon powder, 13 parts of activated carbon, 11 parts of diatomaceous earth, 0.2 parts of compatibilizer, 0.3 parts of light stabilizer, 0.2 parts of antioxidant, 0.3 parts of heat stabilizer and 5 parts of water.

[0064] Fly ash and waste polyurethane foam are added to the raw materials, and flue ash and waste polyurethane foam are used as industrial waste and construction waste, which have been left in the city for a long time or burned and buried, not only occupying urban land, but also polluting the local environme...

Embodiment 3

[0083] A building material comprising the following raw materials in parts by weight: 9 parts of nano-titanium dioxide, 13 parts of asphalt, 15 parts of bauxite, 10 parts of tricalcium silicate, 8 parts of polypropylene resin, 14 parts of phenolic resin, and 10 parts of quartz stone powder , 21 parts of fly ash, 15 parts of waste polyurethane foam, 18 parts of nano-silicon carbide, 13 parts of quartz glass fiber, 15 parts of expanded vitrified microspheres, 11 parts of zircon powder, 17 parts of activated carbon, 21 parts of diatomite, 0.4 parts of compatibilizer, 0.9 parts of light stabilizer, 0.8 parts of antioxidant, 0.7 parts of heat stabilizer and 7 parts of water.

[0084] Fly ash and waste polyurethane foam are added to the raw materials, and flue ash and waste polyurethane foam are used as industrial waste and construction waste, which have been left in the city for a long time or burned and buried, not only occupying urban land, but also polluting the local environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com