Copper nitrate-containing wastewater recovery method, and urea-ammonium nitrate liquid fertilizer preparation method

A recovery method and technology of ammonium nitrate solution are applied in the field of resource recovery and utilization of copper nitrate-containing wastewater, which can solve the problems of limitation, complex reaction conditions and high processing cost, and achieve low cost, high application value and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

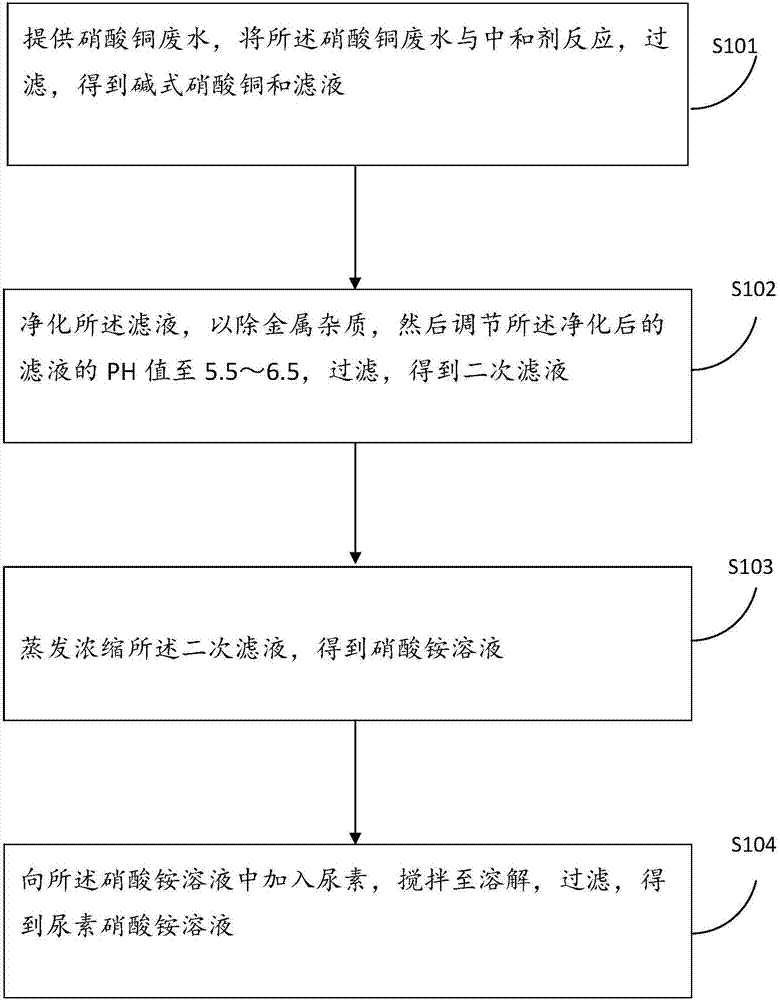

[0028] combine figure 1 , the embodiment of the present invention provides a kind of recovery method that contains copper nitrate waste water and the preparation method of urea ammonium nitrate liquid fertilizer, comprises the following steps:

[0029] S101: Copper nitrate waste water is provided, the copper nitrate waste water is reacted with a neutralizing agent, and filtered to obtain basic copper nitrate and filtrate;

[0030] S102: Purify the filtrate to remove metal impurities, then adjust the pH value of the purified filtrate to 5.5-6.5, and filter to obtain a secondary filtrate;

[0031] S103: evaporating and concentrating the secondary filtrate to obtain an ammonium nitrate solution;

[0032] S104: Add urea to the ammonium nitrate solution, stir until dissolved, and filter to obtain a urea ammonium nitrate solution, which is a urea ammonium nitrate liquid fertilizer.

[0033] The relevant steps are described in detail below.

[0034] In step S101, before the copper...

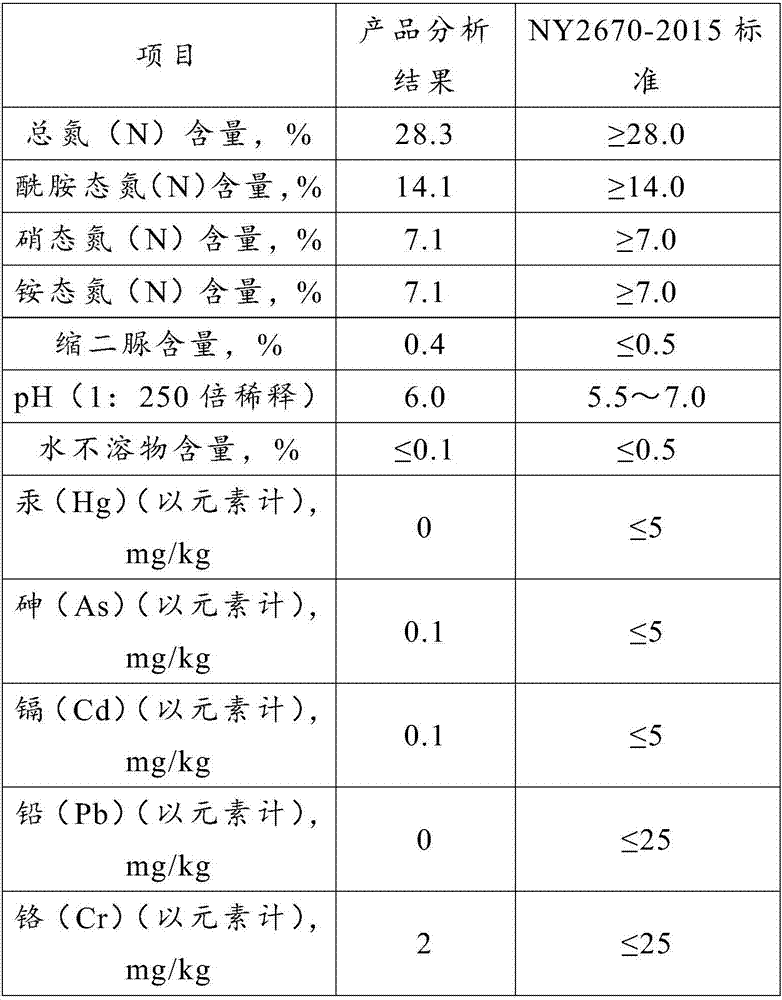

Embodiment 1

[0040] 1L copper nitrate-containing electroplating wastewater (containing about 55g / L copper, H + =0.65g / L) Slowly add ammonia water to adjust the pH to about 2.0, filter to remove insoluble matter, and obtain the clear liquid, add the clear liquid and ammonia water to the reaction kettle to react and synthesize basic copper nitrate, after the reaction is complete Filter to obtain basic copper nitrate product and filtrate;

[0041] After the obtained filtrate is converted into ammonium-type D403 resin to purify and remove copper and other heavy metal impurities, the pH is adjusted to 6.0 with ammonia water;

[0042] The impurity-removed filtrate was evaporated and concentrated under reduced pressure at 0.06MPa and 100°C to obtain NH 4 NO 3 The mass percent is 58% ammonium nitrate solution;

[0043] Add solid urea into the ammonium nitrate solution, stir and dissolve to obtain urea ammonium nitrate solution.

[0044] Gained urea ammonium nitrate solution product specificati...

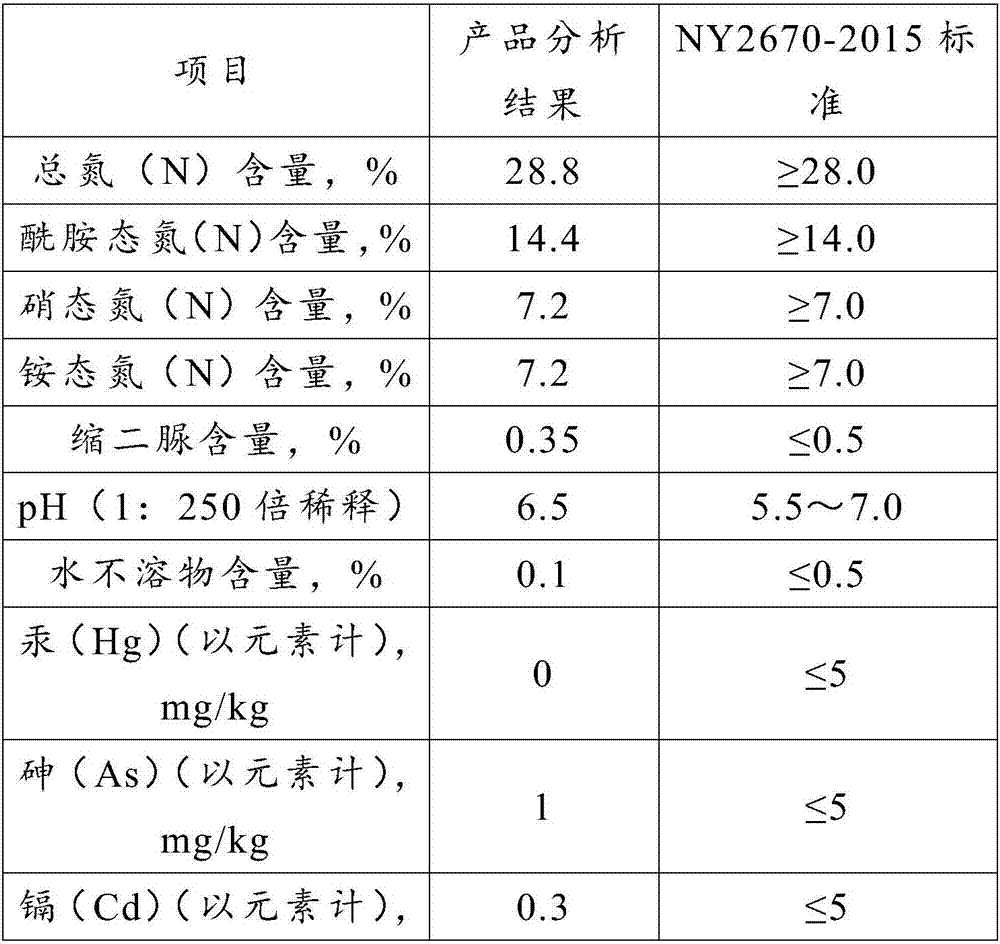

Embodiment 2

[0048] 1L copper nitrate-containing electroplating wastewater (copper containing about 80g / L, H + =0.83g / L) Slowly add ammonia water to adjust the pH to about 3.0, filter to remove insoluble matter, and obtain a clear liquid, add the clear liquid and ammonia water to the reaction kettle to react and synthesize basic copper nitrate, after the reaction is complete Filter to obtain basic copper nitrate product and filtrate;

[0049] After the obtained filtrate is converted into ammonium-type D001 resin to purify and remove copper and other heavy metal impurities, the pH is adjusted to 6.5 with ammonia water;

[0050] The impurity-removed filtrate was evaporated and concentrated under reduced pressure at 0.07MPa and 90°C to obtain NH 4 NO 3 The mass percentage is the ammonium nitrate solution of 58.5%;

[0051] Add solid urea into the ammonium nitrate solution, stir and dissolve to obtain urea ammonium nitrate solution.

[0052] Gained urea ammonium nitrate solution product sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com