TGIC (triglycidyl isocyanurate) cured polyester resin with high toughness and ultrahigh weather fastness for powder coating and preparation method of polyester resin

A technology of powder coating and polyester resin, which is applied in the direction of powder coating, polyester coating, coating, etc., which can solve the problems of unsuitable application in the field of powder coating, poor light resistance, and poor weather resistance, so as to increase hydrolysis resistance and excellent Water resistance, the effect of increasing bending ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

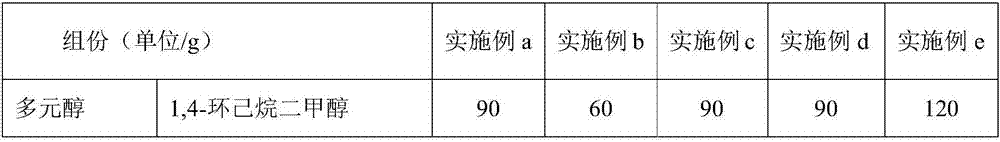

[0042]In a 3000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 90 parts of 1,4-cyclohexanedimethanol, 60 parts of 2-ethyl-2-butyl-1, 3-propanediol, 665 parts of neopentyl glycol, 2 parts of monobutyltin oxide, 770 parts of terephthalic acid, 330 parts of isophthalic acid, nitrogen protection; Acetified water; continue to heat up to 240 ° C, when the water output of the esterified water reaches 95% of the theoretical value, sampling and detection, the acid value reaches 9-11.0mgKOH / g; add 200 parts of polyacid end-capping agent isophthalic acid, in Insulate and react for 240 minutes at 240℃~250℃; after the reaction is completed, take a sample and test, the value reaches 46.0~50.0mgKOH / g, polymerize under negative compression at -0.113~-0.095MPa for 1 hour, and negatively compress at -0.095~-0.099MPa Compress poly for 2 hours; cool down to 220°C, add 2 parts of antioxidant tris(2,4-di-tert-butylphenyl) phosphite and 0.1 part of cur...

Embodiment b

[0044] In a 3000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 60 parts of 1,4-cyclohexanedimethanol, 60 parts of 2-ethyl-2-butyl-1, 3-propanediol, neopentyl glycol 700 parts, monobutyltin oxide 1.5 parts, stannous oxalate 0.5 parts, hydrogenated dimer acid 90 parts, terephthalic acid 660 parts, isophthalic acid 440 parts Formic acid, filled with nitrogen for protection; when the temperature rises to 175°C, esterification water begins to flow out; when the temperature continues to rise to 240°C, when the amount of esterification water reaches 95% of the theoretical value, sampling and testing shows that the acid value reaches 9-11.0mgKOH / g ; Add 200 parts of isophthalic acid, a polybasic acid end-capping agent, and keep it warm for 240 minutes at 240°C to 250°C; after the reaction is completed, take a sample for detection, and the value reaches 46.0 to 50.0mgKOH / g, at -0.113 to -0.095MPa Negative compression polymerization for 1...

Embodiment c

[0046] In a 3000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 90 parts of 1,4-cyclohexanedimethanol, 120 parts of 2-ethyl-2-butyl-1, 3-propanediol, 645 parts of neopentyl glycol, 1 part of monobutyltin oxide, 1 part of stannous oxalate, 120 parts of hydrogenated dimer acid, 880 parts of terephthalic acid, 220 parts of isophthalic acid Formic acid, filled with nitrogen for protection; when the temperature rises to 175°C, esterification water begins to flow out; when the temperature continues to rise to 240°C, when the amount of esterification water reaches 95% of the theoretical value, sampling and testing shows that the acid value reaches 9-11.0mgKOH / g ; Add 200 parts of isophthalic acid, a polybasic acid end-capping agent, and keep it warm for 240 minutes at 240°C to 250°C; after the reaction is completed, take a sample for detection, and the value reaches 46.0 to 50.0mgKOH / g, at -0.113 to -0.095MPa Negative compression polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com