Microfluidic chip based on dielectric electrophoresis and preparation method and application thereof

A technology of microfluidic chips and dielectrophoresis, applied in biochemical equipment and methods, methods for stress-stimulated microbial growth, chemical instruments and methods, etc., can solve problems such as the troublesome preparation of import and export in the packaging process, and affect the efficiency of chip pairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Dielectrophoresis-based microfluidic chip

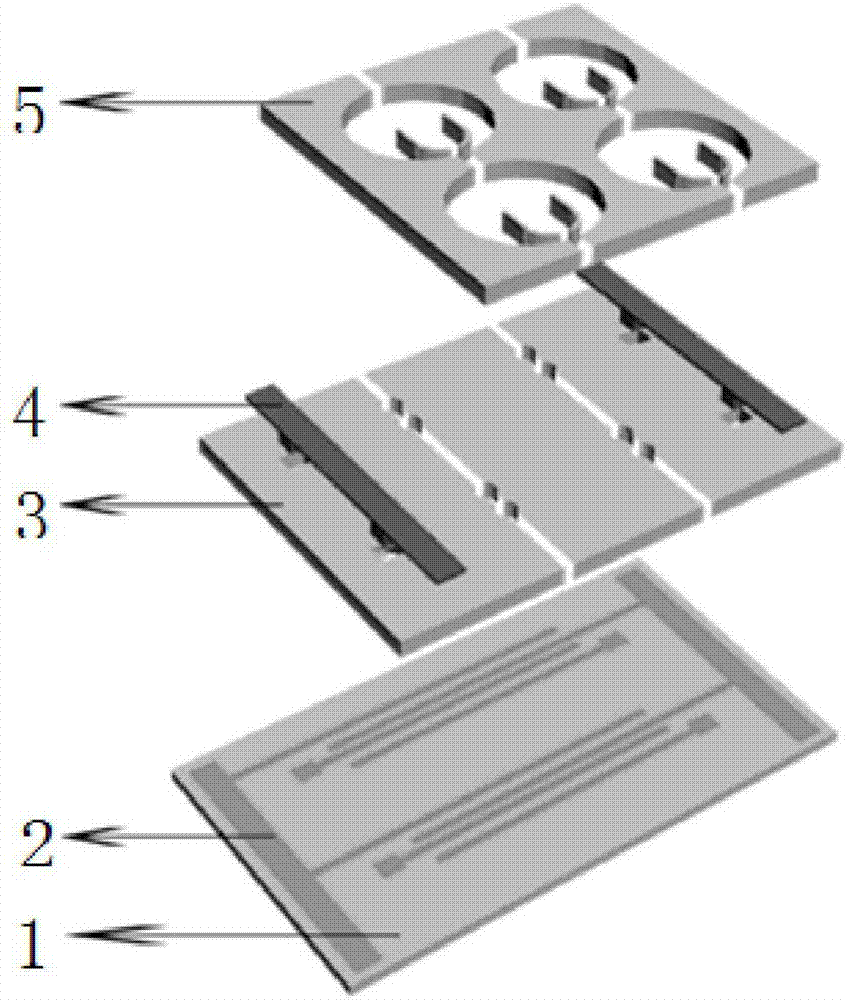

[0080] Such as Figure 6 Shown is a schematic diagram of the microfluidic chip based on dielectrophoresis described in the embodiment of the present invention. The specific structure of the microfluidic chip is as follows Figure 1-5 As shown, the microfluidic chip includes a planar chip 16 at the bottom and a microfluidic channel 13 at the top, and the planar chip has a four-layer structure stacked in sequence;

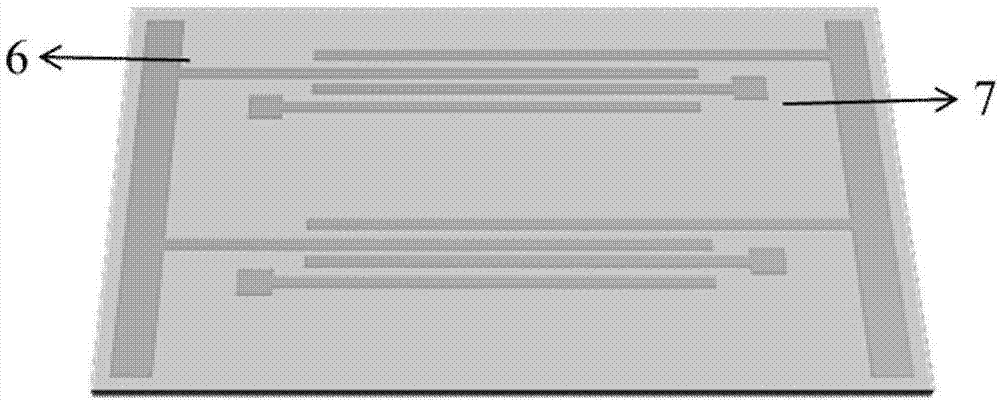

[0081] The first layer structure 1 of the planar chip includes ITO electrodes on the glass substrate, the ITO electrodes are interdigital electrodes 2, the number of the interdigital electrodes 2 is 2-10, and the width of the interdigital electrodes 2 is 10-30 μm, the distance between two electrodes in the interdigital electrodes 6 is 3-10 μm, and the distance between the interdigital electrodes 6 and 7 is 5-50 μm;

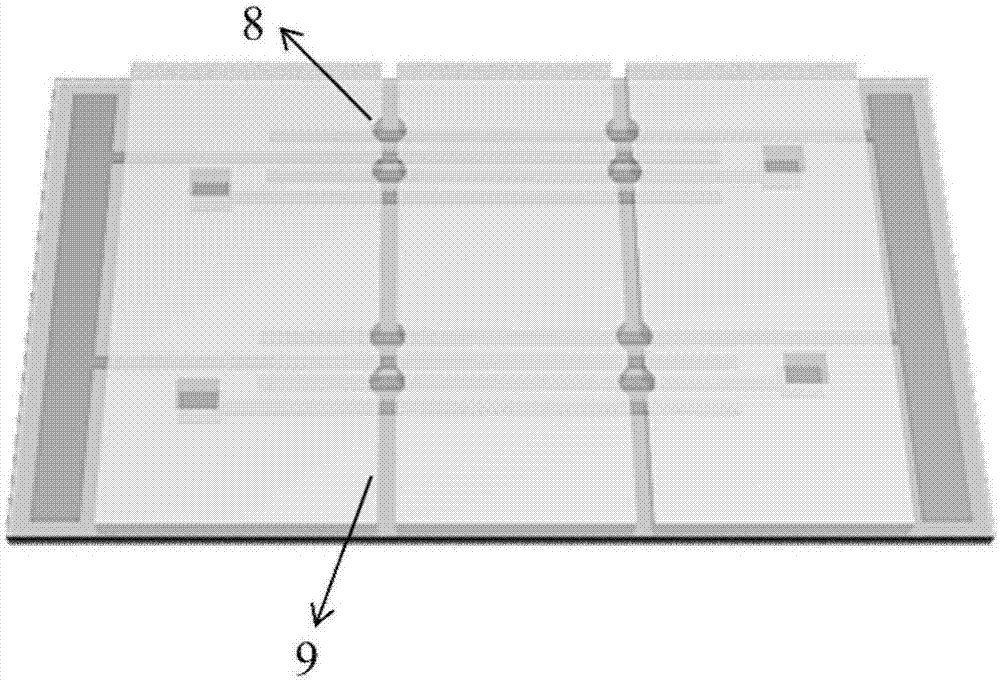

[0082] The second layer structure 3 of the planar chip is SU-8 negative glue, the second...

Embodiment 2

[0096] Example 2: Dielectrophoresis-based microfluidic chip

[0097] The microfluidic chip includes a planar chip 16 at the bottom and a microfluidic channel 13 at the top, and the planar chip has a four-layer structure stacked in sequence;

[0098] The first layer structure 1 of the planar chip includes ITO electrodes on a glass substrate, the ITO electrodes are interdigital electrodes 2, the number of the interdigital electrodes 2 is 2, and the width of the interdigital electrodes 2 is 20 μm , the distance between two electrodes in the interdigitated electrodes 6 is 6 μm, and the distance between the interdigitated electrodes 6 and 7 is 10 μm;

[0099] The second layer structure 3 of the planar chip is SU-8 negative glue, the second layer structure 3 shown includes a microcavity array 8 for cell capture, the diameter of the microcavity array 8 is 20 μm, and the microcavity The depth of the array 8 is 10 μm;

[0100] The third layer structure 4 of the planar chip includes a...

Embodiment 3

[0107] Example 3: Capture and pairing of cells

[0108] The microfluidic chip based on dielectrophoresis described in Example 2 is used to capture and pair cells, and the specific steps are as follows:

[0109] 1) Prepare two fluorescently labeled cell dispersions of different colors: stain the cells with two fluorescently labeled dyes, and then disperse the two kinds of cells emitting red light and green light in a low-conductivity buffer to obtain 2×10 6 / mL cell concentration of the dispersion;

[0110] 2) Put the green fluorescent cell dispersion liquid in the sampling flow channel 14 of the micro flow channel 13 on the microfluidic chip, with a flow rate of 10 μL / min, generate a non-uniform electric field between the interdigital electrodes 6 applying a sinusoidal AC signal, so that Under the action of positive dielectrophoretic force, the cells are captured into the microcavity array 8 on one side, captured for 3-5 minutes, and the excess cells are washed away with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com