Double elliptical track groove reciprocating transmission piston type, diaphragm type compressor

A technology for driving pistons and elliptical orbits, which is applied in the direction of machines/engines, liquid variable displacement machines, mechanical equipment, etc. It can solve the problems of increasing energy consumption of balance mass, unstable flow, pipeline vibration, etc., and achieves the elimination of high-speed reciprocating inertia Shock vibration, increase safety and reliability, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

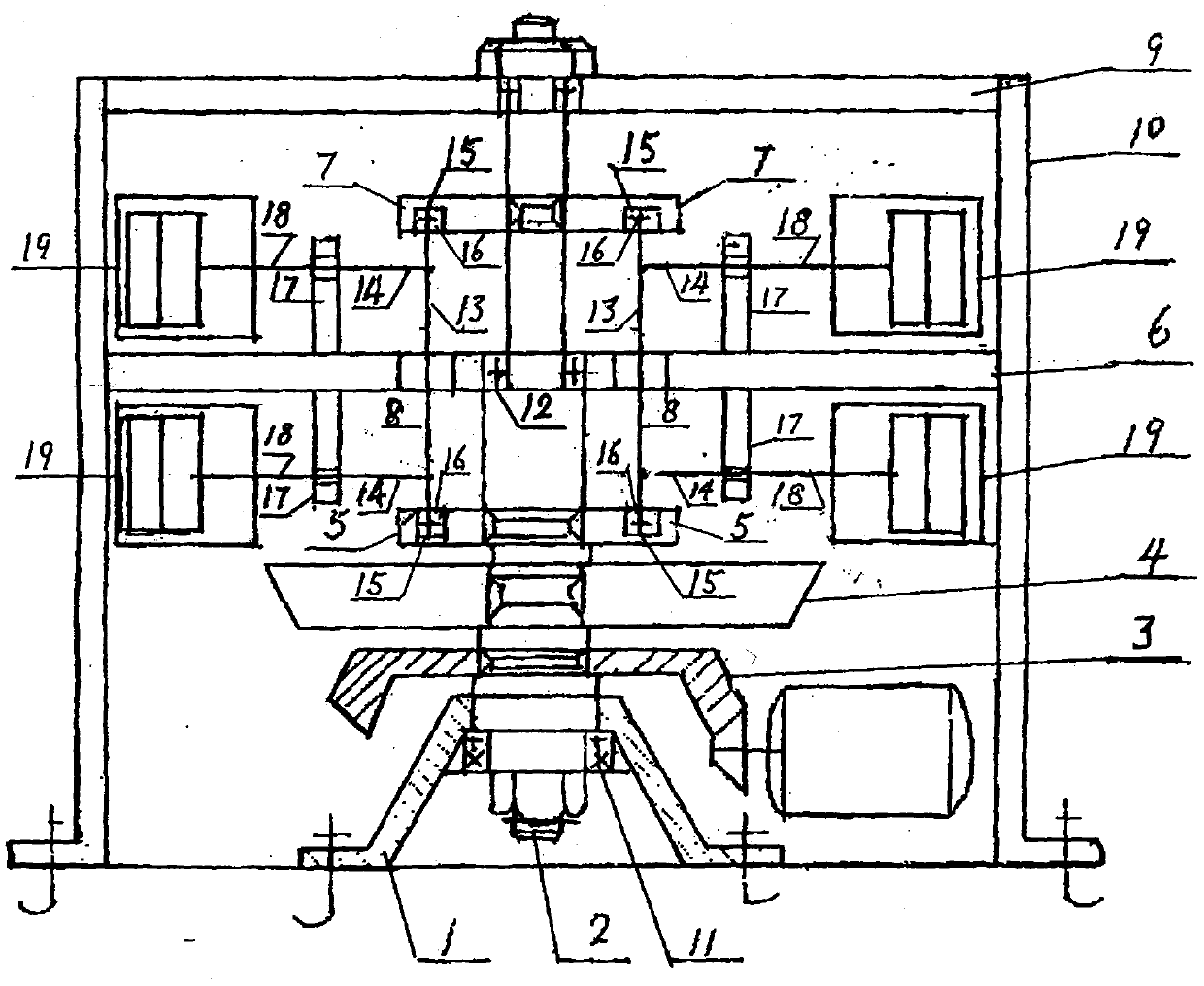

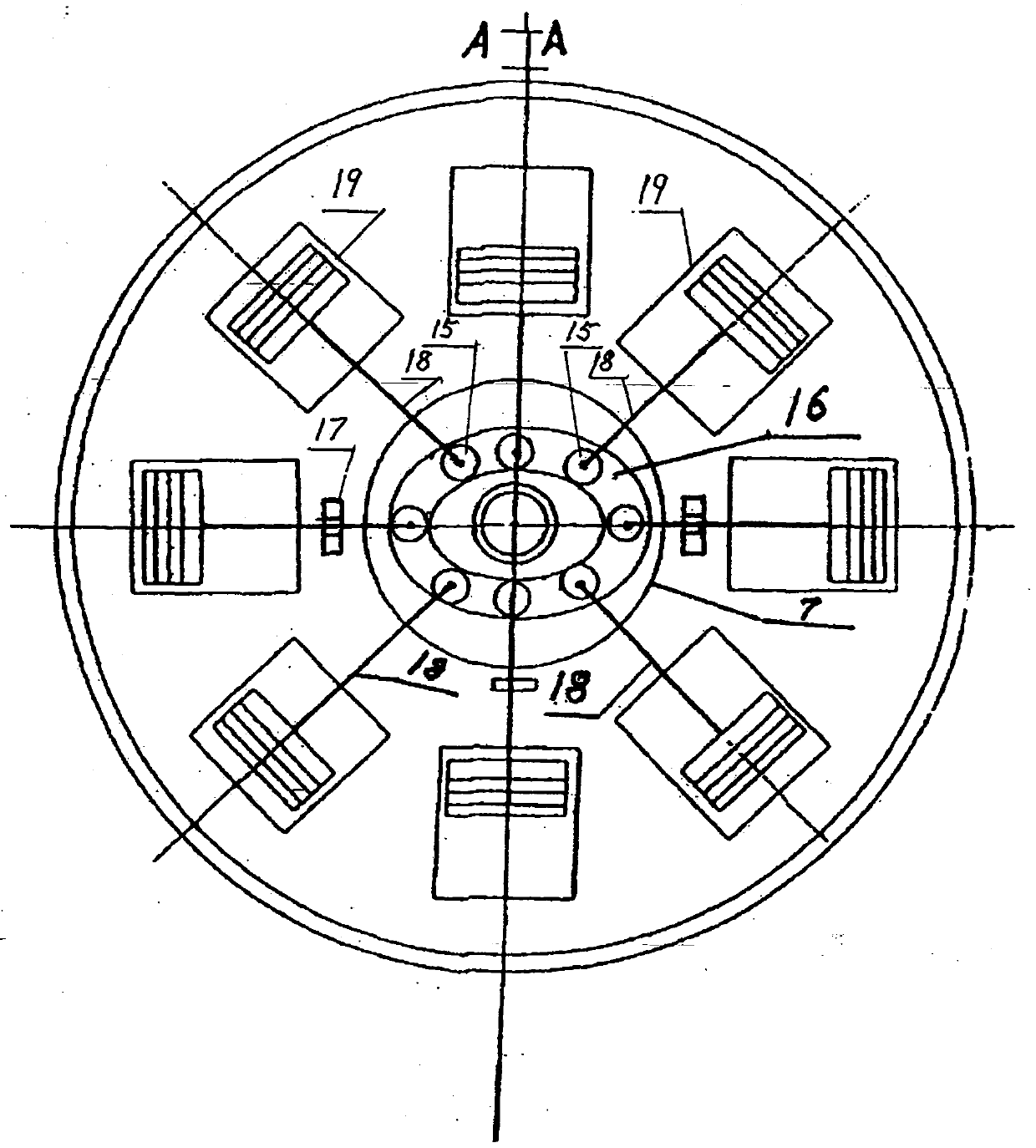

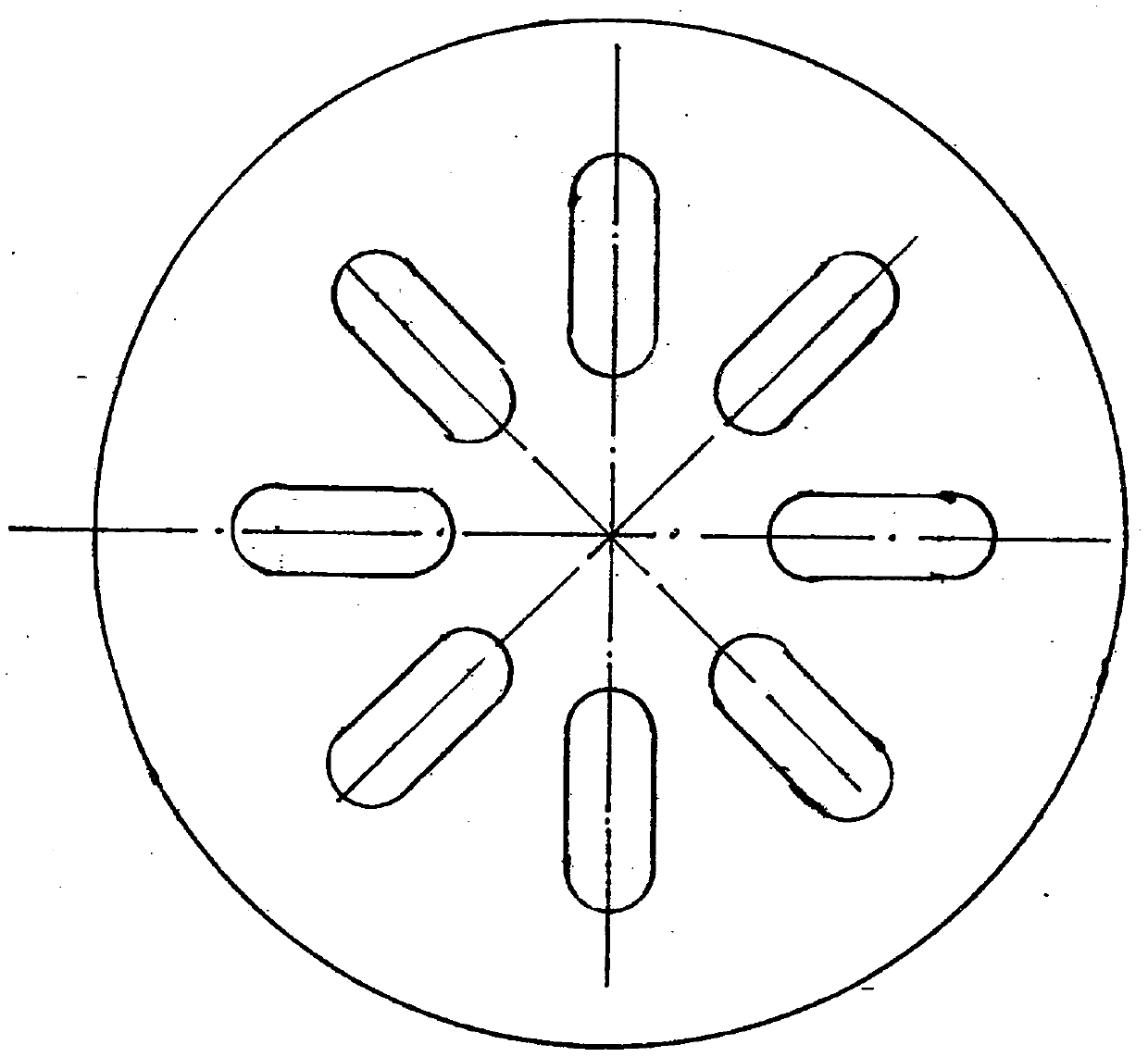

[0015] The reciprocating transmission piston-type and diaphragm-type compressors with double elliptical track grooves of the present invention use oil-free, water-free silent piston-type compressor heads (19) to be symmetrically installed on the tray (6) in even numbers, and each end face of the tray Eight machine heads can be installed, and the centerline of each machine head must be able to perpendicularly intersect with the center line of the main shaft in the air. The intake and exhaust pipes of each machine head are connected in series to form an intake and exhaust manifold; The head just constitutes a single-row compressor, and the upper and lower end faces are all equipped with a machine head to form a double-row compressor; the upper and lower ends of the vertical rod (13) of the double T-shaped rolling connecting rod (8) are each equipped with a sliding The bearing (15) passes through the long hole of the tray (6) and is inserted into the vertically symmetrical ellipti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com