Cristobalite as well as preparation method and application thereof

A cristobalite, weight technology, applied in chemical instruments and methods, condensation hydrocarbon production with dehydrogenated hydrocarbons, catalyst carriers, etc., can solve the problems of limited industrial application of products, high energy consumption, complex processes, etc. Low cost, low energy consumption and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing cristobalite, the method comprising: contacting silicon dioxide with a tungstate solution and then drying, and keeping the dried solid at 600-850°C for 0.5-24h.

[0028] According to the method of the present invention, the weight ratio of the amount of silicon dioxide to the amount of tungstate solution can be 1:1-20, preferably 1:1-5; the concentration of the tungstate solution can be 0.01 -30% by weight, preferably 0.01-15% by weight, more preferably 0.01-8% by weight.

[0029] According to the method of the present invention, the dissolving and contacting of the silicon dioxide and the tungstate refers to uniformly mixing the silicon dioxide and the tungstate solution so that the silicon dioxide can be fully dispersed in the tungstate solution. The method of contacting the silicon dioxide with the tungstate solution is not particularly limited, as long as the silicon dioxide can be fully dispersed in the tun...

Embodiment 1

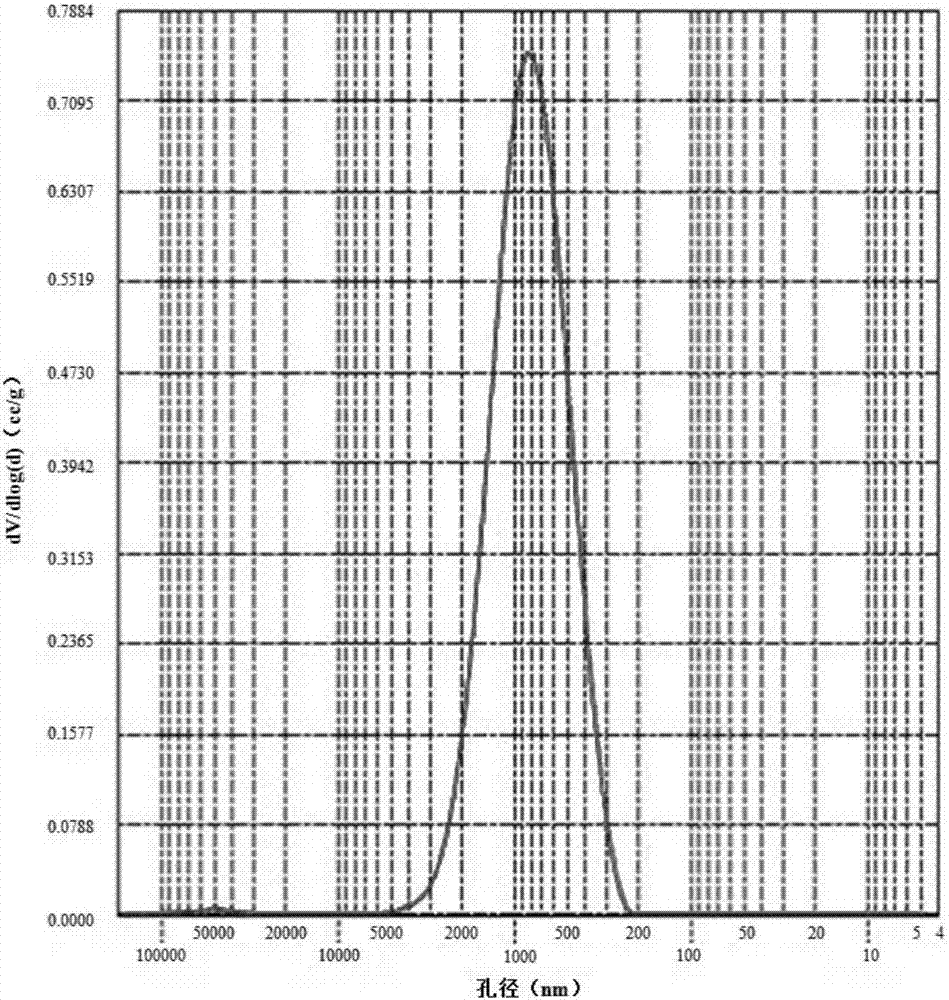

[0039] Weigh 0.28g of sodium tungstate, add 10g of distilled water, dissolve completely, then add 5g of silicon dioxide, stir well, place in a constant temperature drying oven at 120°C for 2 hours, and place the dried solid in a muffle furnace for 5 The temperature was raised to 700°C at a rate of °C / min, and kept at 700°C for 4 hours to obtain porous cristobalite. It can be seen from the calculation based on the amount of material fed that the obtained porous cristobalite contains 95.2% by weight of silicon dioxide and 3.6% by weight of tungsten components calculated as oxides. After measurement, the specific pore volume of the obtained porous cristobalite is 0.6777ml / g, the average pore diameter is about 788.6nm, and the most probable pore diameter is 568.5nm.

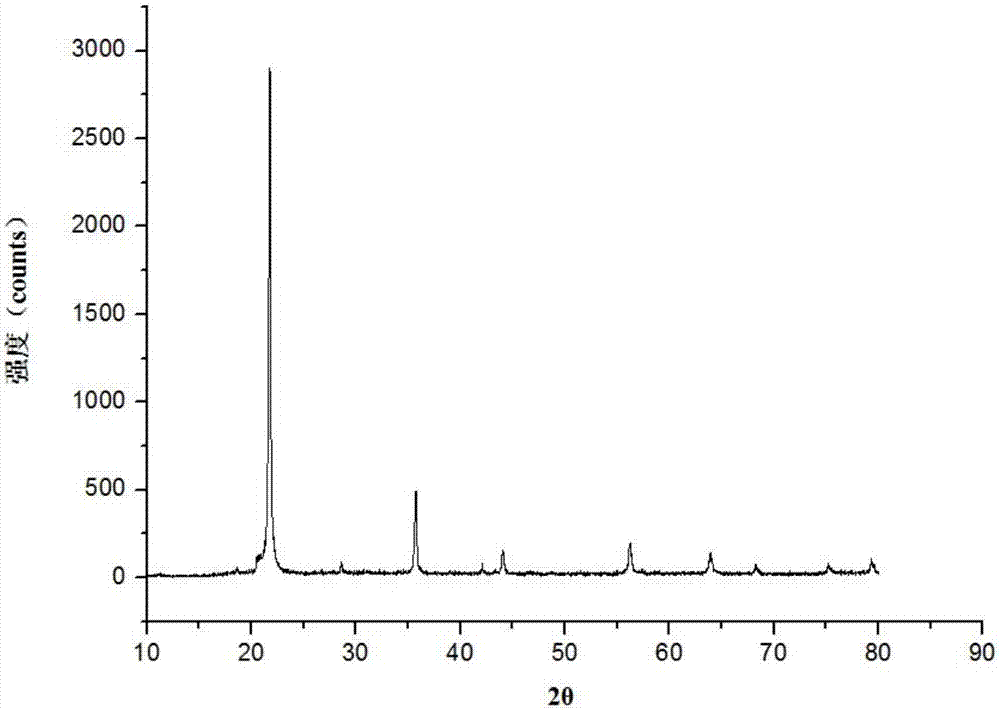

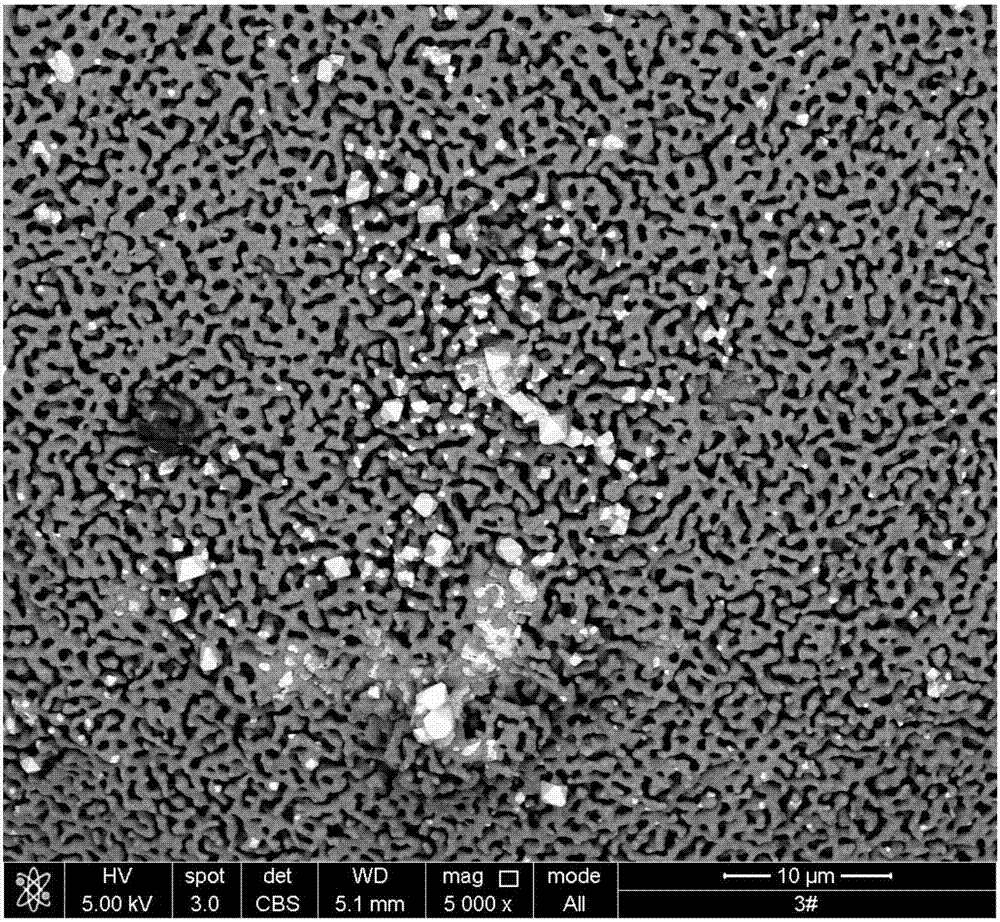

[0040] Get the cristobalite that makes, it carries out scanning electron microscope (SEM), X-ray diffraction (XRD) and pore size distribution detection to it, and detection result is respectively as follows figure 1...

Embodiment 2

[0042] Weigh 0.5g of sodium tungstate and add it into 15g of distilled water. After the dissolution is complete, then add 5g of silicon dioxide. After fully stirring, place it in a constant temperature drying oven at 110°C for 3 hours. The dried solid is placed in a muffle furnace and heated in 3 The temperature was raised to 750°C at a rate of °C / min, and kept at 750°C for 5 hours to obtain porous cristobalite. It can be known from the calculation based on the feeding amount of materials that the obtained porous cristobalite contains 91.8% by weight of silicon dioxide and 6.2% by weight of tungsten components calculated as oxides. After measurement, the specific pore volume of the obtained porous cristobalite is 0.51ml / g, the average pore diameter is about 526.4nm, and the most probable pore diameter is 496.7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com