Preparation method of high performance and low thermal expansion coefficient polyimide film

A technology of polyimide film and low thermal expansion coefficient is applied in the field of preparation of high-performance low thermal expansion coefficient polyimide film, which can solve problems such as unfavorable size and stability, and achieve reduced thermal expansion coefficient, good mechanical properties, and no warping. the effect of the song

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

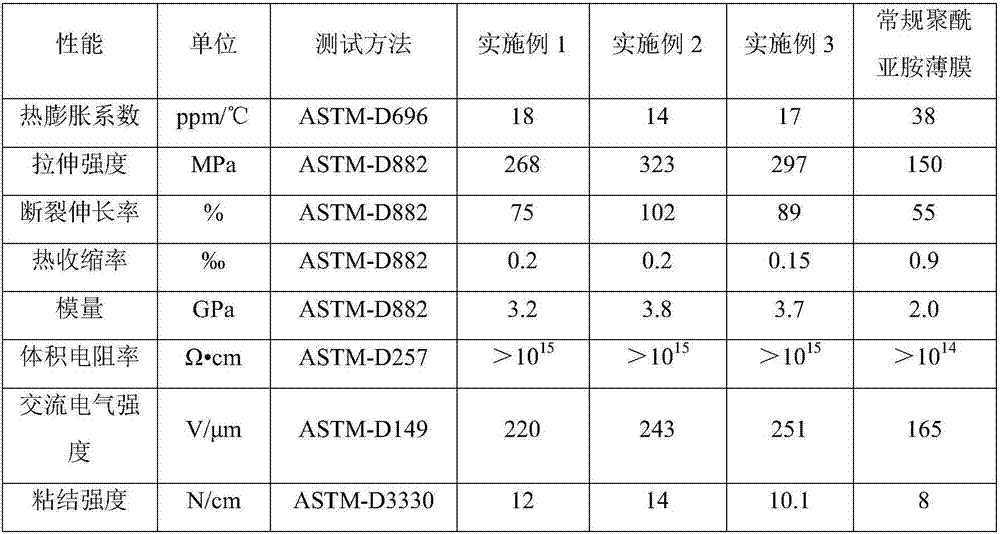

Examples

Embodiment 1

[0023] A preparation method of a polyimide film with high performance and low coefficient of thermal expansion, comprising the following steps:

[0024] (1) In a dissolving kettle at 60°C and normal pressure, the nano-SiO which will account for 5wt% of the final product is 2 and 1wt% silane coupling agent were added to the dimethylformamide solution, and ultrasonically mixed for 30 minutes to prepare solution A;

[0025] (2) Put biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether in solution A for in-situ polymerization at 20°C in an atmospheric pressure reactor filled with nitrogen, and biphenyltetracarboxylic The molar ratio of anhydride and 4,4'-diaminodiphenyl ether is 0.992:1. During the polymerization reaction, first dissolve 4,4'-diaminodiphenyl ether in solution A, and then add biphenyl in four times Tetracarboxylic dianhydride, in the process of adding biphenyl tetracarboxylic dianhydride, the time interval between two adjacent additions is 30 minutes,...

Embodiment 2

[0031] A preparation method of a polyimide film with high performance and low coefficient of thermal expansion, comprising the following steps:

[0032] (1) In a dissolution kettle at 75°C and normal pressure, nano-SiO, which accounts for 10% of the final product, will be 2 and 3% silane coupling agent were added to the dimethylformamide solution, and ultrasonically mixed for 60 minutes to prepare solution A;

[0033] (2) Put biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether in solution A for in-situ polymerization at 35°C in an atmospheric pressure reactor filled with nitrogen, and biphenyltetracarboxylic dianhydride The molar ratio of 4,4'-diaminodiphenyl ether to 4,4'-diaminodiphenyl ether is 0.995:1. During the polymerization reaction, first dissolve 4,4'-diaminodiphenyl ether in solution A, and then add biphenyl four times Formic dianhydride, in the process of adding biphenyltetracarboxylic dianhydride, the time interval between two adjacent additions is...

Embodiment 3

[0039] A preparation method of a polyimide film with high performance and low coefficient of thermal expansion, comprising the following steps:

[0040] (1) In a dissolution kettle at 80°C and normal pressure, nano-SiO, which accounts for 15% of the final product, will be 2 and 5% silane coupling agent were added to the dimethylformamide solution, and ultrasonically mixed for 90 minutes to prepare solution A;

[0041] (2) Put biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether in solution A for in-situ polymerization at 40°C in an atmospheric pressure reactor filled with nitrogen, and biphenyltetracarboxylic dianhydride The molar ratio of 4,4'-diaminodiphenyl ether to 4,4'-diaminodiphenyl ether is 0.998:1. During the polymerization reaction, first dissolve 4,4'-diaminodiphenyl ether in solution A, and then add biphenyl four times Formic dianhydride, in the process of adding biphenyltetracarboxylic dianhydride, the time interval between two adjacent additions is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com