Hydrogen sensor and preparation method thereof

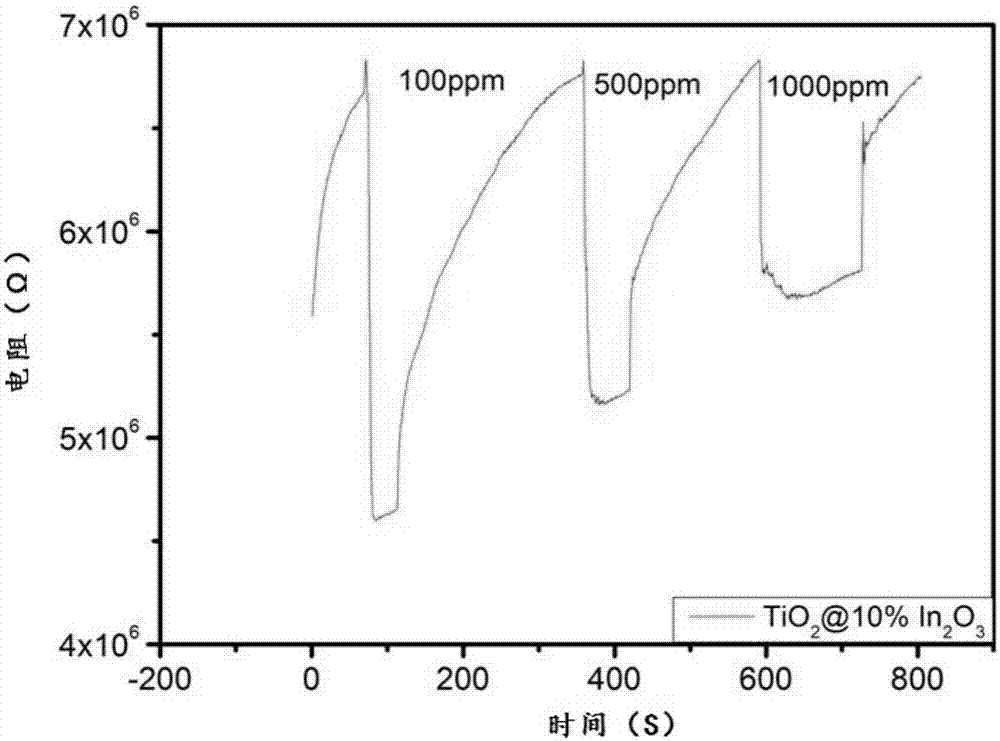

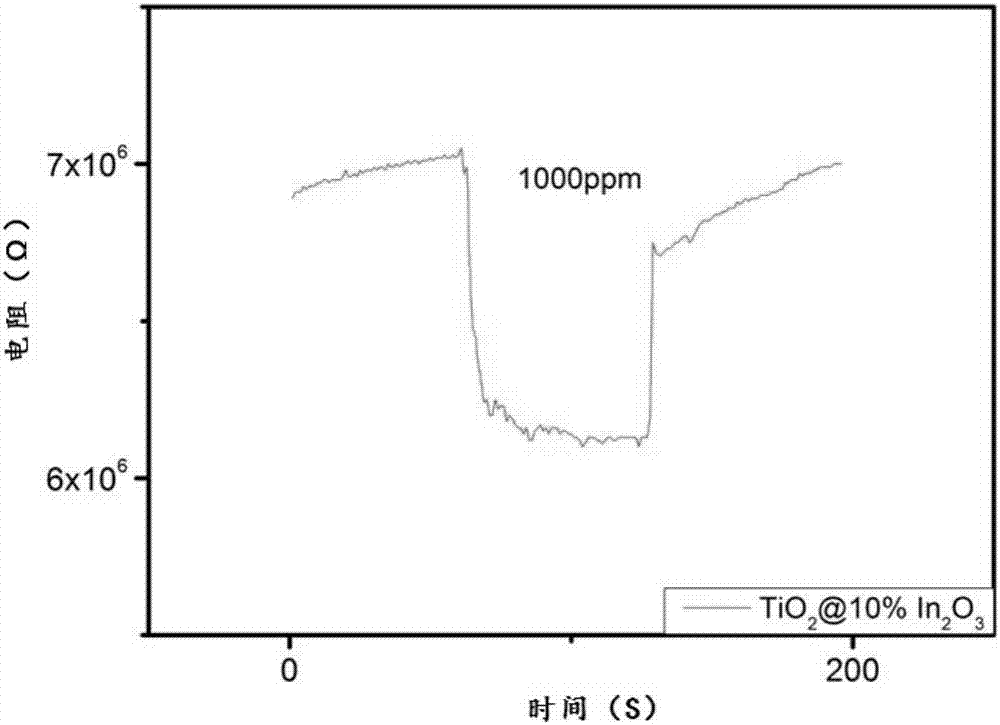

A sensor and hydrogen technology, applied in the field of hydrogen sensors, can solve the problems of poor recovery performance of titanium dioxide sensors, increased response time and recovery time, complex porous structure manufacturing methods, etc., to achieve a wide range of hydrogen concentration, fast response and recovery, and preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the hydrogen sensor provided by the present invention comprises the following steps:

[0033] S1, respectively weighing predetermined masses of titanium dioxide and indium oxide, and mixing the two;

[0034] Predetermined masses of titanium dioxide and indium oxide are weighed respectively, and then the titanium dioxide and indium oxide are mixed. The mass of the above-mentioned indium oxide accounts for 0-20% of the total mass of the two. In the present invention, the titanium dioxide may be anatase phase titanium dioxide or rutile phase titanium dioxide, or may be a mixed phase of anatase phase titanium dioxide and rutile phase titanium dioxide.

[0035] Before performing step S1, an annealing step of the titanium dioxide and the indium oxide may also be included. Specifically, the titanium dioxide was kept at a temperature of 450° C. for 1 hour and then cooled naturally. The indium oxide was kept at 600° C. for 1 hour and then cooled natu...

Embodiment 1

[0047] First, titanium dioxide is mixed with nanometer indium oxide, wherein the titanium dioxide is titanium dioxide in anatase phase, and the indium oxide accounts for 10% of the total mass of the titanium dioxide and the indium oxide. The configured titanium dioxide and indium oxide are placed in an agate ball mill jar for ball milling, the speed of the agate ball mill jar is 300r / min, and the milling time is 6h;

[0048] Then weigh 1 g of the powder of titanium dioxide and indium oxide after ball milling, place it in a tableting mold, and then use a tableting machine to press under a pressure of 10Gpa for 5 minutes to form a tablet;

[0049] Then heat-treat the compressed tablet, first raising the temperature to 100°C for 2 hours, then raising the temperature to 600°C for 4 hours;

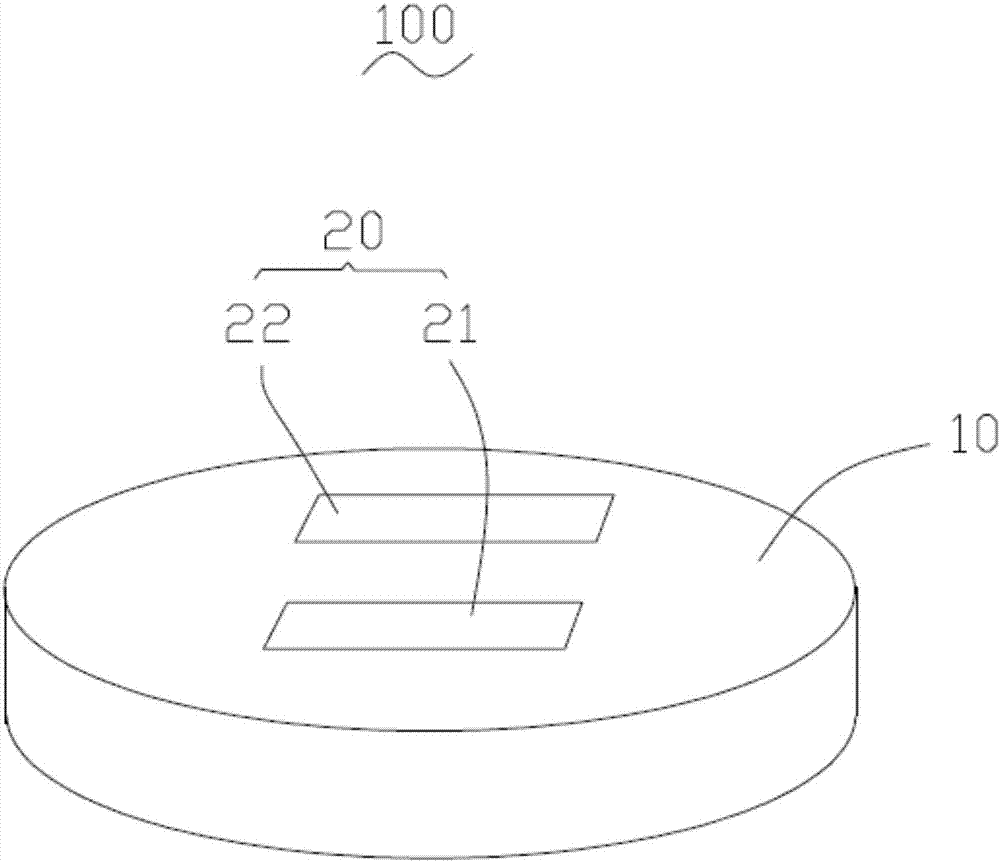

[0050] A layer of Pt electrodes was sputtered on the surface of the heat-treated sheet, wherein the number of the Pt electrodes was two, and the distance between the two Pt electrodes was 5 mm,...

Embodiment 2

[0053] First, titanium dioxide is mixed with nanometer indium oxide, wherein the titanium dioxide is titanium dioxide in a rutile phase, and the indium oxide accounts for 10% of the total mass of the titanium dioxide and the indium oxide. The configured titanium dioxide and indium oxide are placed in an agate ball mill jar for ball milling, the speed of the agate ball mill jar is 400r / min, and the milling time is 4h;

[0054] Then weigh 1 g of the powder of titanium dioxide and indium oxide after ball milling, place it in a tableting mold, and then use a tableting machine to press for 7 minutes under a pressure of 8 Gpa to form a tablet;

[0055] Then heat-treat the compressed tablet, first raising the temperature to 150°C for 1 hour, then raising the temperature to 400°C for 4 hours;

[0056] A layer of Pt electrodes was sputtered on the surface of the heat-treated sheet, wherein the number of the Pt electrodes was two, and the distance between the two Pt electrodes was 5 mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com