Copper-based amorphous solder ball for area array packaging and preparation method and packaging method of copper-based amorphous solder ball

A packaging method and surface array technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex preparation method, high equipment requirements, low efficiency, etc., and achieve stable chemical composition and equipment requirements. High and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

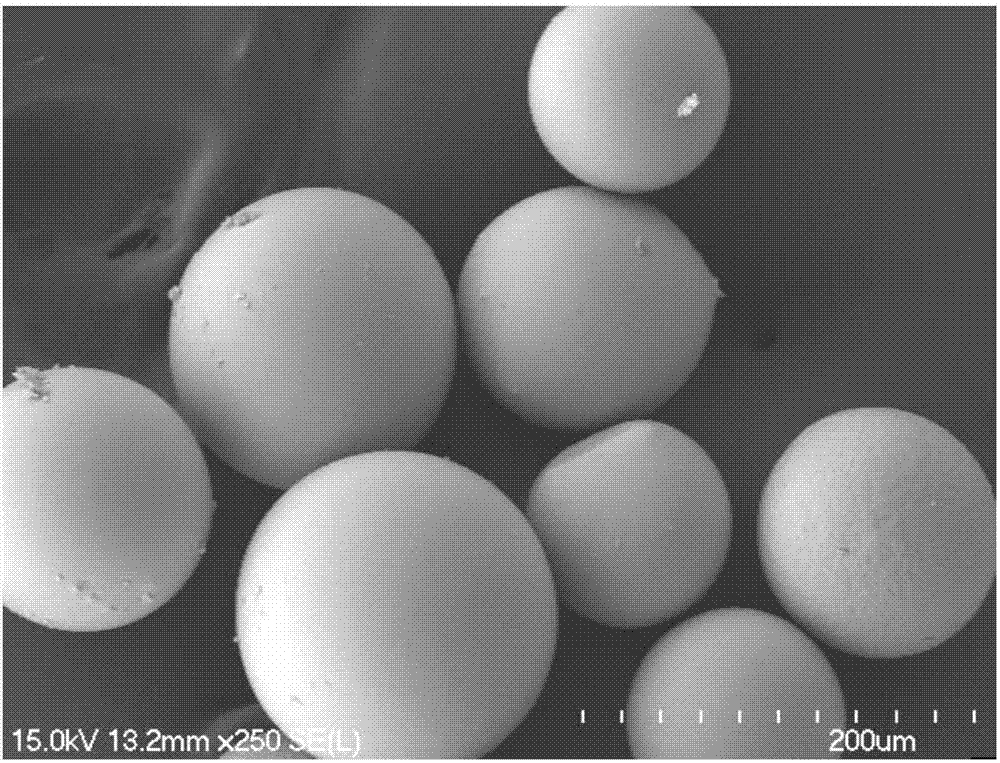

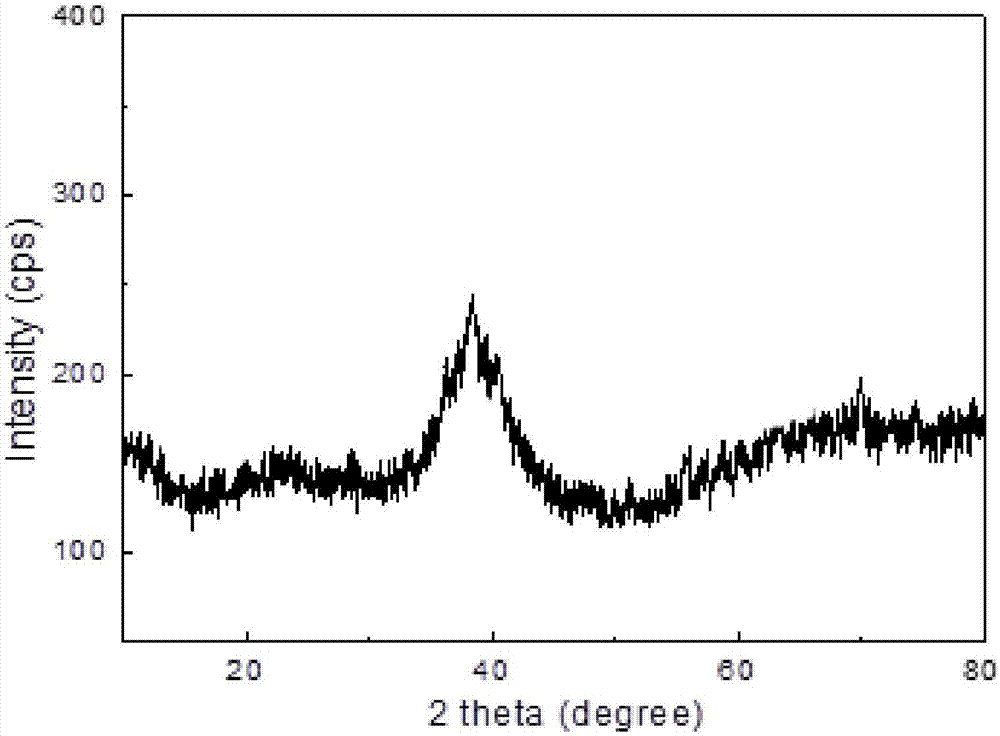

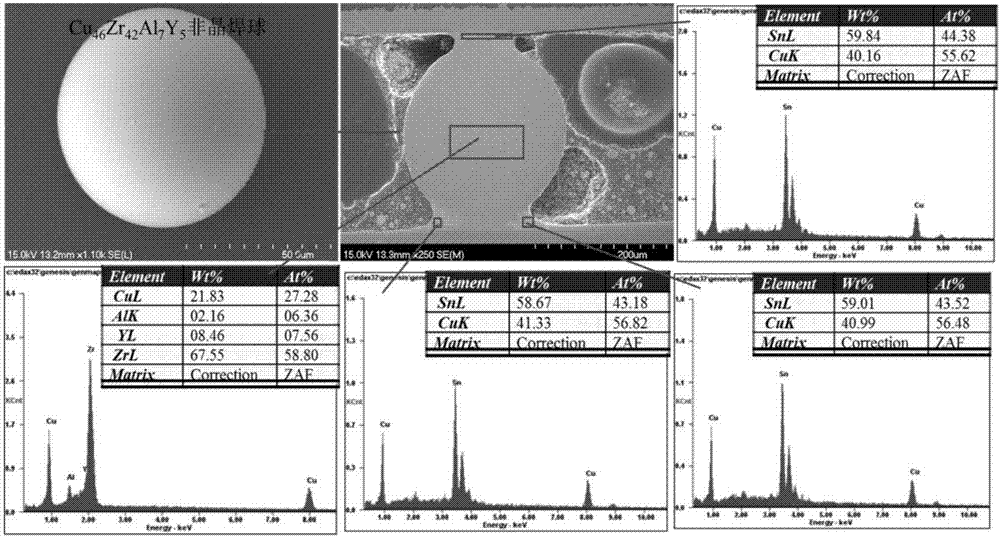

Embodiment 1

[0041] Use a balance to weigh 39.1g of Cu with a purity of 99.99%, 53.6g of Zr with a purity of 99.9%, 1.6g of Al with a purity of 99.99%, and 5.8g of Y with a purity of 99.9%, and slightly polish the surface with water sandpaper to remove part of the oxide film , put it in the melting crucible after drying with cold air, and the flow rate into the melting crucible is 0.1m 3 / h Ar gas or nitrogen, under the action of induction coil, copper and tin are melted into an alloy, and the alloy is smelted repeatedly for 3 times. After cooling to room temperature, stop the ventilation, take out the alloy, and cut it into small pieces of alloy within 10*10*20mm , placed in a vertical gas atomization nozzle, induction heated to a molten state under the protection of nitrogen or argon, nitrogen or argon impacts the molten alloy ejected from the nozzle under the pressure of nitrogen or argon, to achieve gas atomization powder making , to obtain the powder mixture that has been preliminaril...

Embodiment 2

[0045] Use a balance to weigh 39.1g of Cu with a purity of 99.99%, 53.6g of Zr with a purity of 99.9%, 1.6g of Al with a purity of 99.99%, and 5.8g of Y with a purity of 99.9%, and slightly polish the surface with water sandpaper to remove part of the oxide film , put it in the melting crucible after drying with cold air, and the flow rate into the melting crucible is 0.1m 3 / h Ar gas or nitrogen, under the action of induction coil, copper and tin are melted into an alloy, and the alloy is smelted repeatedly for 3 times. After cooling to room temperature, stop the ventilation, take out the alloy, and cut it into small pieces of alloy within 10*10*20mm , placed in a vertical gas atomization nozzle, induction heated to a molten state under the protection of nitrogen or argon, nitrogen or argon impacts the molten alloy ejected from the nozzle under the pressure of nitrogen or argon, to achieve gas atomization powder making , to obtain the powder mixture that has been preliminaril...

Embodiment 3

[0048] Use a balance to weigh 33.6g of Cu with a purity of 99.99%, 58g of Zr with a purity of 99.9%, 2.5g of Al with a purity of 99.99%, and 5.9g of Y with a purity of 99.9%. The surface is lightly polished with water sandpaper to remove part of the oxide film, and cool air After drying, put it in the melting crucible, and the flow rate into the melting crucible is 0.1m 3 / h Ar gas or nitrogen, under the action of induction coil, copper and tin are melted into an alloy, and the alloy is smelted repeatedly for 3 times. After cooling to room temperature, stop the ventilation, take out the alloy, and cut it into small pieces of alloy within 10*10*20mm , placed in a vertical gas atomization nozzle, induction heated to a molten state under the protection of nitrogen or argon, nitrogen or argon impacts the molten alloy ejected from the nozzle under the pressure of nitrogen or argon, to achieve gas atomization powder making , to obtain the powder mixture that has been preliminarily si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com