A kind of preparation method of reconstituted tobacco leaf additive

A technology of reconstituted tobacco leaves and additives, applied in tobacco, tobacco treatment, fermentation, etc., can solve the problems of loss of aroma components, difficult extraction, insufficient aroma of reconstituted tobacco leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

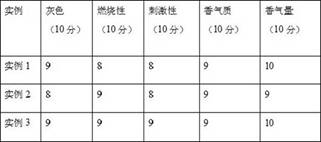

Examples

example 1

[0021] Example 1 makes reconstituted tobacco leaf additive

[0022] In parts by weight, get 90 parts of water, 43 parts of beef extract, 33 parts of peptone, 32 parts of agar, 13 parts of sodium chloride, 10 parts of potassium nitrate, 5 parts of potassium dihydrogen phosphate, 3 parts of dipotassium hydrogen phosphate and 1.3 parts part of magnesium sulfate, stir evenly, collect the stirred mixture, and put it into an ultraviolet germicidal lamp for sterilization to obtain a nutritional matrix; take Goubao and put it in a pulverizer for crushing, pass through a 150-mesh sieve, collect the sifted Goubao powder, press The mass ratio is 1:9, put the sieved Goubao powder and nutrient matrix into a fermenter, set the temperature at 36°C, stir and ferment at 130r / min for 4 days; after the fermentation is over, put the fermentation mixture in the fermenter Put into a masher, mash with 12000r / min for 10min, filter the mixture in the masher, collect the filtrate, and put the filtrate ...

example 2

[0023] Example 2 makes reconstituted tobacco leaf additive

[0024]In parts by weight, get 80 parts of water, 40 parts of beef extract, 28 parts of peptone, 26 parts of agar, 11 parts of sodium chloride, 8 parts of potassium nitrate, 2 parts of potassium dihydrogen phosphate, 1 part of dipotassium hydrogen phosphate and 0.9 part of magnesium sulfate, stir evenly, collect the stirred mixture, and put it into an ultraviolet germicidal lamp for sterilization to obtain a nutritional matrix; take Goubao and put it in a pulverizer for crushing, pass through a 150-mesh sieve, collect the sifted Goubao powder, press The mass ratio is 1:7, put the sieved Goubao powder and nutrient matrix into a fermenter, set the temperature at 28°C, stir and ferment at 130r / min for 2 days; after the fermentation is over, put the fermentation mixture in the fermenter Put into a masher, mash with 12000r / min for 5min, filter the mixture in the masher, collect the filtrate, and put the filtrate into a vac...

example 3

[0025] Example 3 makes reconstituted tobacco leaf additive

[0026] In parts by weight, get 85 parts of water, 42 parts of beef extract, 30 parts of peptone, 31 parts of agar, 12 parts of sodium chloride, 9 parts of potassium nitrate, 3 parts of potassium dihydrogen phosphate, 2 parts of dipotassium hydrogen phosphate and 1.0 part of magnesium sulfate, stir evenly, collect the stirred mixture, and put it into an ultraviolet germicidal lamp for sterilization to obtain a nutritional matrix; take Goubao and put it in a pulverizer for crushing, pass through a 150-mesh sieve, collect the sifted Goubao powder, press The mass ratio is 1:8, put the sieved Goubao powder and nutrient matrix into a fermenter, set the temperature at 35°C, stir and ferment at 130r / min for 3 days; after the fermentation is over, put the fermentation mixture in the fermenter Put it into a masher, mash it with 12000r / min for 7min, filter the mixture in the masher, collect the filtrate, and put the filtrate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com