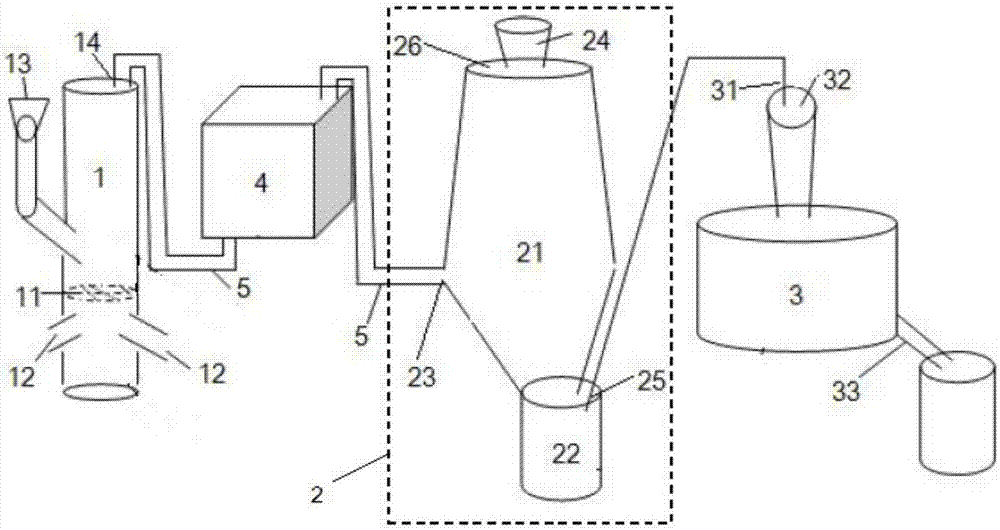

System and method for fluidized bed gas production, gas-based reduction and electric steelmaking coupling

An electric furnace steelmaking and fluidized bed technology, applied in electric furnaces, furnaces, shaft furnaces, etc., can solve the problems of large energy consumption, large equipment investment, long process flow, etc., to reduce energy consumption, reduce production costs, reduce system The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Dry the crushed and screened coal and lime with a particle size of 2-8mm in the drying furnace. The heat source of coal drying is: gas-based direct reduction shaft furnace top gas flue gas, and the shaft furnace top gas temperature is 450°C. Moisture pulverized coal is transported to the fluidized bed silo for use, and the coal is added through the screw feeder.

[0095] First, the raw coal and desulfurizer are fed into the fluidized bed from the feeder from the silo, and the mass ratio of coal to desulfurizer is 100:1.5. All water vapor is introduced from the bottom of the bed. In order to better couple with the direct reduction process of the shaft furnace, the molar ratio of carbon to water vapor in the pulverized coal during the production process is 1.15:1. The pressure in the bed is controlled at 0.25MPa, and the bed temperature is 850°C. The contents of carbon dioxide and water vapor in the gas at the outlet of the fluidized bed were 6.52% and 5.39%, respectivel...

Embodiment 2

[0113] The semi-coke and calcium carbonate with a particle size of 2-8 mm after crushing and screening are transported to the fluidized bed silo for use, and the coal is added through a screw feeder.

[0114] First, the raw coal and desulfurizer are fed into the fluidized bed from the feeder from the silo, and the mass ratio of coal to desulfurizer is 100:1. All the pure oxygen is fed from the bottom of the bed. In order to better couple with the direct reduction process of the shaft furnace, the molar ratio of carbon to pure oxygen in the pulverized coal during the production process is 1.1:1. The pressure in the bed is controlled at 0.4MPa, and the bed temperature is 750°C. The contents of carbon dioxide and water vapor in the gas at the outlet of the fluidized bed are 6.01% and 5.33%, respectively. The main principle of fluidized bed coal gasification:

[0115] C+H 2 O=CO+H 2 , C+O 2 =CO 2 , C+CO 2 =2CO, and methane and CnHm gas obtained by decomposition of volatile ...

Embodiment 3

[0134] Dry the coal and dolomite with a particle size of 2-8mm after crushing and screening. The dehydrated coal powder is transported to the fluidized bed silo for use, and the coal is added through the screw feeder.

[0135] First, the raw coal and desulfurizer are fed into the fluidized bed from the feeder from the silo, and the mass ratio of coal to desulfurizer is 100:1.5. The mixture of water vapor and pure oxygen is completely fed from the bottom of the bed. In order to better couple with the direct reduction process of the shaft furnace, the molar ratio of carbon in the pulverized coal to the mixture of water vapor and pure oxygen in the production process is 1.15:1. The pressure in the bed is controlled at 0.8MPa, and the bed temperature is 750°C. The contents of carbon dioxide and water vapor in the gas at the outlet of the fluidized bed are 6.25% and 5.12%, respectively. The main principle of fluidized bed coal gasification:

[0136] C+H 2 O=CO+H 2 , C+O 2 =CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com