Technology and device for treating catalytic cracking desulfurization waste water

A technology of desulfurization wastewater and catalytic cracking, applied in the field of water treatment, can solve the problems that enterprises cannot bear, high treatment cost, high salt content, etc., and achieve the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

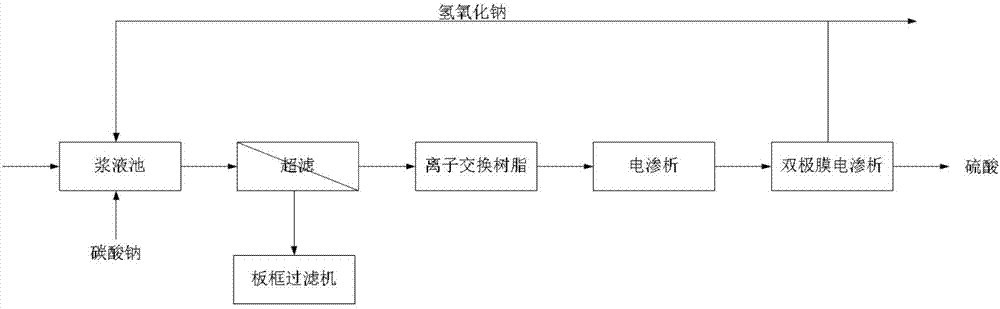

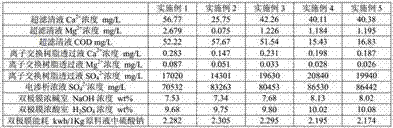

[0046] use as figure 1 In the device shown, the catalytic cracking desulfurization wastewater is discharged into the slurry tank, mixed and reacted with the dosing agent containing sodium hydroxide and sodium carbonate, and the concentration of NaOH is higher than that of Mg in completely precipitated brine 2+ Concentration greater than 0.1g / L, Na 2 CO 3 The dosing concentration is higher than the Ca in the complete precipitation brine 2+ and Ba 2+ The maximum concentration is 0.2g / L.

[0047] The waste water after the reaction enters the ultrafiltration, and the ultrafiltration membrane used is a ceramic membrane with an average pore size of 50nm, which intercepts the suspended matter such as magnesium hydroxide and calcium carbonate to realize solid-liquid separation. The ultrafiltration permeate is used in the resin system to deeply remove metal ions such as calcium and magnesium. The sodium-type cation exchange resin is used, and the flow rate of the upper column liqui...

Embodiment 2

[0050] use as figure 1 In the device shown, the catalytic cracking desulfurization wastewater is discharged into the slurry tank, mixed and reacted with the dosing agent containing sodium hydroxide and sodium carbonate, and the concentration of NaOH is higher than that of Mg in completely precipitated brine 2+ Concentration greater than 0.3g / L, Na 2 CO 3 The dosing concentration is higher than the Ca in the complete precipitation brine 2+ and Ba 2+ The maximum concentration is 0.4g / L.

[0051] The waste water after the reaction enters the ultrafiltration, and the ultrafiltration membrane adopted is a ceramic membrane with an average pore size of 20nm, which intercepts the generated suspended matter such as magnesium hydroxide and calcium carbonate, and realizes solid-liquid separation. The ultrafiltration permeate is used in the resin system to deeply remove metal ions such as calcium and magnesium. The sodium-type cation exchange resin is used, and the flow rate of the up...

Embodiment 3

[0054] use as figure 1 In the device shown, the catalytic cracking desulfurization wastewater is discharged into the slurry tank, mixed and reacted with the dosing agent containing sodium hydroxide and sodium carbonate, and the concentration of NaOH is higher than that of Mg in completely precipitated brine 2+ Concentration greater than 0.2g / L, Na 2 CO 3 The dosing concentration is higher than the Ca in the complete precipitation brine 2+ and Ba 2+ The maximum concentration is 0.2g / L.

[0055] The waste water after the reaction enters the ultrafiltration, and the ultrafiltration membrane used is a ceramic membrane with an average pore size of 50nm, which intercepts the suspended matter such as magnesium hydroxide and calcium carbonate to realize solid-liquid separation. The ultrafiltration permeate is used in the resin system to deeply remove metal ions such as calcium and magnesium. The sodium-type cation exchange resin is used, and the flow rate of the upper column liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com