High-sustained-release-performance organic composite fertilizer capable of realizing high yield of black mustard

A high-yield, slow-release technology of black mustard, applied in the direction of organic fertilizer, urea compound fertilizer, nitrogen fertilizer, etc., can solve the problems of reducing the yield and quality of black mustard, soil compaction, and easy deterioration and fermentation of organic fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

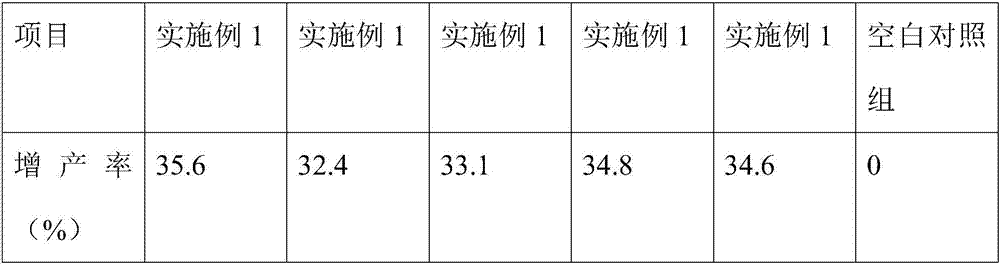

Examples

Embodiment 1

[0015] A kind of black mustard high-yield and high slow-release organic compound fertilizer of the present invention, its raw material comprises by weight: 100 parts of cow dung, 5 parts of corn stalks, 2.5 parts of furfural residue, 4.5 parts of soybean meal powder, 3.5 parts of castor cake, wheat 4.5 parts of rice stone powder, 6.5 parts of shell powder, 4 parts of chitin, 2.5 parts of fish bone meal, 3.5 parts of calcium aspartate, 3.5 parts of potassium humate, 4 parts of calcium nitrate mud, 4 parts of magnesium nitrate mud, 30 parts of urea, 2.5 parts of ammonium nitrate, 4 parts of calcium dihydrogen phosphate, 4 parts of amino acid chelated zinc, 6 parts of zinc sulfate, 9 parts of manganese sulfate, 6.5 parts of zinc acetate, 3.5 parts of molybdenum sulfate, 3 parts of modified slow-release agent, anti-mold additive 4.5 parts of agent, 6 parts of antibacterial powder.

[0016] The modified slow-release agent is prepared according to the following process: mix 4 parts ...

Embodiment 2

[0020] A black mustard high-yield and high-slow-release organic compound fertilizer of the present invention, its raw materials include by weight: 80 parts of cow dung, 8 parts of corn stalks, 1.5 parts of furfural residue, 6 parts of soybean meal powder, 2 parts of castor cake, wheat 6 parts of rice stone powder, 5 parts of shell powder, 6 parts of chitin, 1 part of fish bone meal, 4 parts of calcium aspartate, 2 parts of potassium humate, 5 parts of calcium nitrate mud, 2 parts of magnesium nitrate mud, 40 parts of urea, 1 part of ammonium nitrate, 6 parts of calcium dihydrogen phosphate, 3 parts of amino acid chelated zinc, 8 parts of zinc sulfate, 6 parts of manganese sulfate, 9 parts of zinc acetate, 2 parts of molybdenum sulfate, 4 parts of modified slow-release agent, anti-mildew aid 3 parts of agent, 8 parts of antibacterial powder.

[0021] The modified slow-release agent is prepared according to the following process: mix 3 parts of casein and 8 parts of water in par...

Embodiment 3

[0025] A kind of black mustard high-yield and high-slow-release organic compound fertilizer of the present invention, its raw material comprises by weight: 120 parts of cow dung, 2 parts of corn stalks, 3.5 parts of furfural residue, 3 parts of soybean meal powder, 5 parts of castor cake, wheat 3 parts of rice stone powder, 8 parts of shell powder, 2 parts of chitin, 4 parts of fish bone meal, 3 parts of calcium aspartate, 5 parts of potassium humate, 3 parts of calcium nitrate mud, 6 parts of magnesium nitrate mud, 20 parts of urea, 4 parts of ammonium nitrate, 2 parts of calcium dihydrogen phosphate, 5 parts of amino acid chelated zinc, 4 parts of zinc sulfate, 12 parts of manganese sulfate, 4 parts of zinc acetate, 5 parts of molybdenum sulfate, 2 parts of modified slow-release agent, anti-mold auxiliary 6 parts of agent, 4 parts of antibacterial powder.

[0026] The modified sustained-release agent is prepared according to the following process: mix 5 parts of casein and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com