Environment-friendly and efficient waste paper deinking method

A waste paper deinking and waste paper technology, which is applied in the field of papermaking, can solve the problems of inability to achieve quality, efficiency, environmental protection, cumbersome addition of deinking agent, and inability to meet the needs of deinking, and achieve excellent biodegradability and efficient Facilitate the removal and increase the effect of hydrolysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

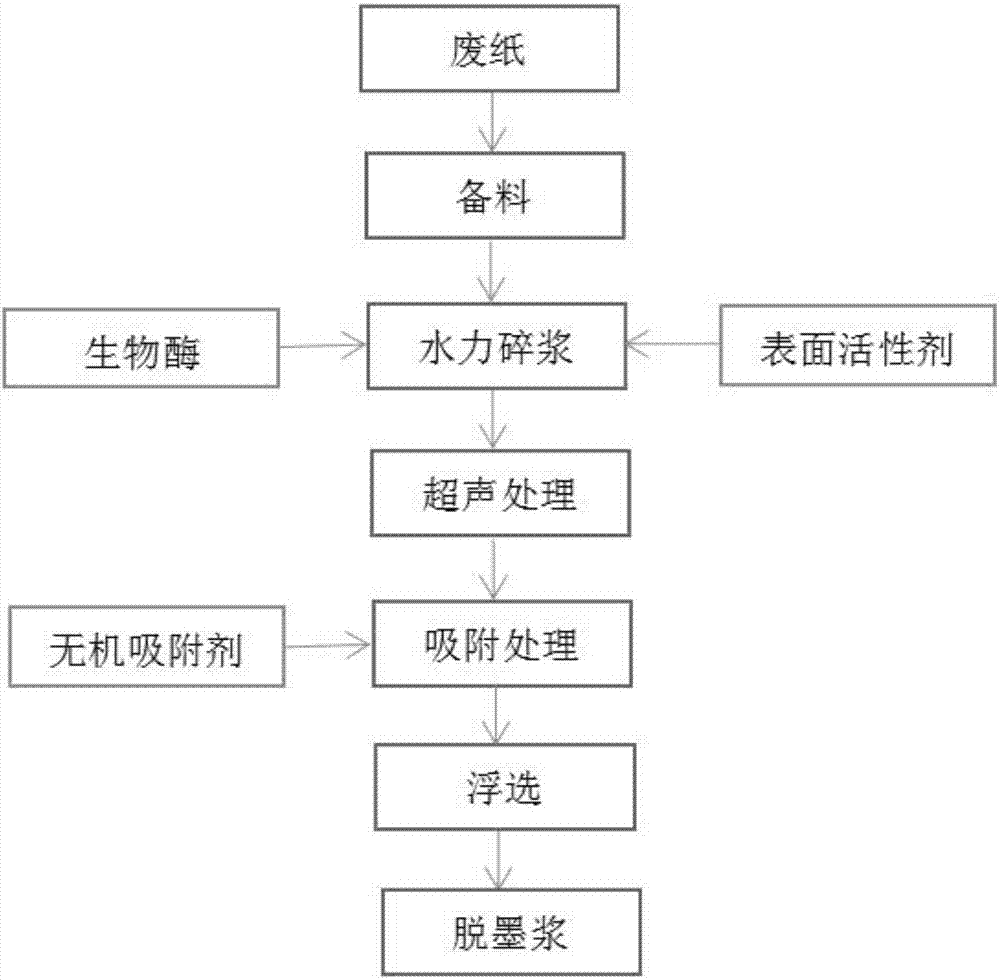

Method used

Image

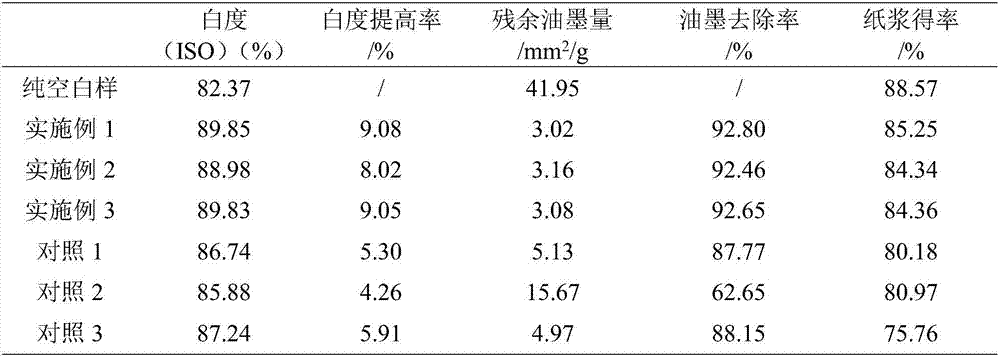

Examples

Embodiment 1

[0032] Follow the steps below for deinking:

[0033] (1) Tear the mixed office waste paper into small pieces of 2cm×2cm, mix well, add appropriate amount of water and soak for 20min.

[0034] (2) Add 15U / g cutinase, 5U / g amylase, 10U / g lipase in turn; The mass ratio of phenol sulfonate and fatty alcohol polyoxyethylene ether sulfate is 2:1:1; it is evenly stirred with waste paper, and placed in a hydraulic pulper for pulping. The slurry concentration is controlled at 10%, the rotational speed of the pulper is 200r / min, the pulping time is 60min, and the pulping temperature is 50°C.

[0035] (3) After pulping, the slurry is subjected to ultrasonic treatment, the frequency is 45KHz, and the treatment time is 20min.

[0036](4) After the ultrasonic treatment is completed, the slurry is properly diluted, and zeolite is added to the pulp for adsorption treatment, the slurry concentration is 1%, and the treatment time is 20 minutes. After the adsorption is completed, gradient cen...

Embodiment 2

[0040] Follow the steps below for deinking:

[0041] (1) Tear the mixed office waste paper into small pieces of 2cm×2cm, mix well, add appropriate amount of water and soak for 10min.

[0042] (2) add 5U / g cutinase, 15U / g amylase, 10U / g lipase successively; Surfactant addition is 0.2% of waste paper dry mass, in surfactant, cardanol polyoxyethylene ether, The mass ratio of cardanol sulfonate and fatty alcohol polyoxyethylene ether sulfate is 1:1:2: Stir with waste paper evenly, and place it in a hydraulic pulper for pulping. The slurry concentration is controlled at 9%, the rotational speed of the pulper is 200r / min, the pulping time is 30min, and the pulping temperature is 40°C.

[0043] (3) After pulping, the slurry is subjected to ultrasonic treatment, the frequency is 40KHz, and the treatment time is 10min.

[0044] (4) After the ultrasonic treatment is completed, the slurry is properly diluted, and diatomaceous earth is added to the pulp for adsorption treatment, the slu...

Embodiment 3

[0048] (1) Tear the mixed office waste paper into small pieces of 2cm×2cm, mix well, add appropriate amount of water and soak for 20min.

[0049] (2) add 10U / g cutinase, 5U / g amylase, 15U / g lipase successively; Surfactant addition is 0.4% of waste paper dry mass, in surfactant, cardanol polyoxyethylene ether, The mass ratio of cardanol sulfonate and fatty alcohol polyoxyethylene ether sulfate is 1:1:2; it is evenly stirred with waste paper, and placed in a hydraulic pulper for pulping. The slurry concentration is controlled at 8%, the speed of the pulper is 250r / min, the pulping time is 40min, and the pulping temperature is 50°C.

[0050] (3) After the pulping is finished, the slurry is subjected to ultrasonic treatment, the frequency is 50KHz, and the treatment time is 30min.

[0051] (4) After the ultrasonic treatment is completed, the slurry is properly diluted, and sepiolite is added to the pulp for adsorption treatment, the slurry concentration is 3%, and the treatment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com