Photocatalytic hollow silica optical fiber and manufacturing method

A technology of quartz optical fiber and manufacturing method, which is applied in the field of hollow optical fiber, can solve the problems of organic pollutant efficiency that affects light energy utilization efficiency, strong penetrating ability of refracted and scattered light, and low optical radiation flux on the surface of optical fiber, etc., and achieves excellent visible light response Features, Inexpensive, Improving Transmission Mode Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

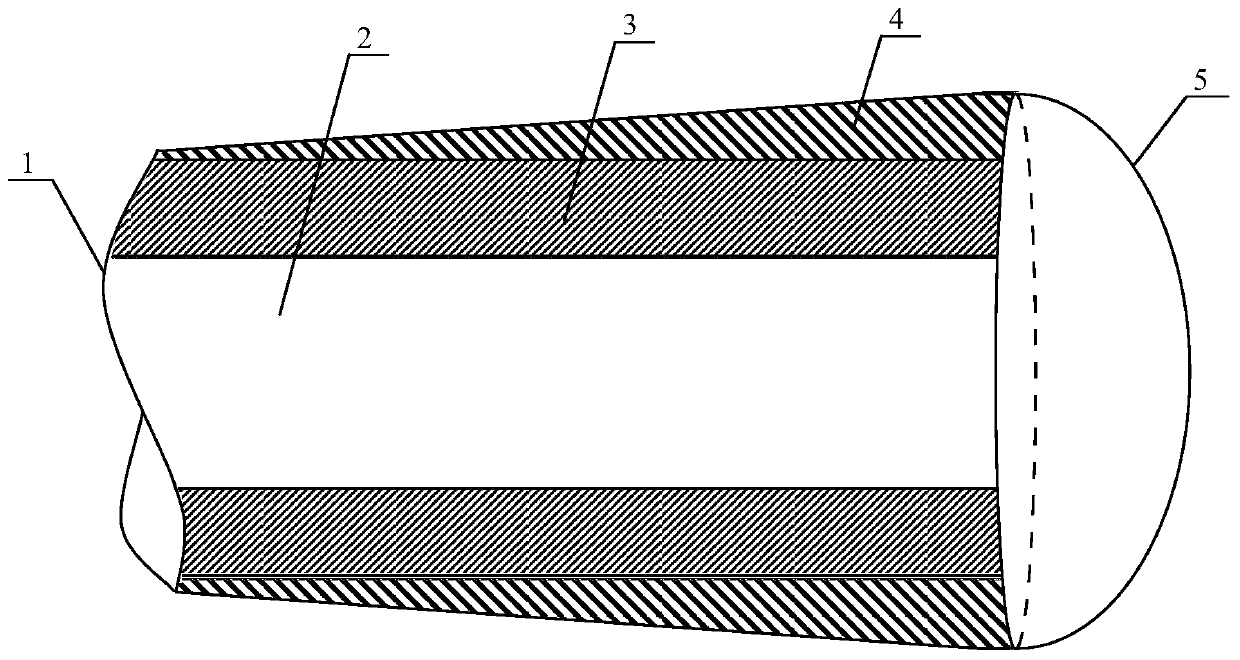

[0028] Embodiment 1: A kind of preparation method of photocatalytic hollow silica fiber, comprises the following steps

[0029] A. A hollow quartz tube is selected as the base material of the hollow optical fiber, and the rear end of the hollow quartz tube is sealed.

[0030] B. Up-conversion luminescent agent Er 3+ :YAlO 3 preparation of

[0031] B1. Take Al(NO 3 ) 3 9(H 2 O), Er(NO 3 ) 3 5(H 2 O) and Y (NO 3 ) 3 6(H 2 O) be dissolved in distilled water, and be placed on stirrer and stir to make it dissolve completely; In specific embodiment, Al(NO 3 ) 3 9(H 2 O), Er(NO 3 ) 3 5(H 2 O) and Y (NO 3 ) 3 6(H 2 O) Dissolve in distilled water at a mass ratio of 0.8-1.1:0.005-0.02:1.00.

[0032] B2. Add solid citric acid to the mixed solution obtained in step B1; in a specific embodiment, the molar ratio of solid citric acid to metal ions in the mixed solution is 2.0-4.0:1.

[0033] B3. Put the mixed solution obtained in step B2 in a water bath at 80-90°C until ...

Embodiment 2

[0042] Embodiment 2: A kind of preparation method of photocatalytic hollow silica fiber, comprises the following steps

[0043] A. Select a hollow quartz tube with a length of 1-100 cm, an outer diameter of 2-30 mm, and an inner diameter of 1-28 mm as the base material of the hollow optical fiber, and the rear end of the hollow quartz tube is sealed.

[0044] B. Up-conversion luminescent agent Er 3+ :YAlO 3 preparation of

[0045] B1. Take 18.7566g of Al(NO 3 ) 3 9(H 2O), 0.2218g of Er(NO 3 ) 3 5(H 2 O) and 18.9616g Y(NO 3 ) 3 6(H 2 O) Dissolve in 30-80ml of distilled water, and stir in a stirrer for 1-2 hours to completely dissolve. The final product stoichiometry is Er 0.99 Y 0.01 al 1.00 .

[0046] B2. Add 60-70 g of solid citric acid to the mixed solution obtained in step B1; the molar ratio of solid citric acid to metal ions in the mixed solution is 3:1.

[0047] B3. Put the mixed solution obtained in step B2 in a water bath at 80-90°C until a light yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com