Micro-patterned wetted surface, preparation method of micro-patterned wetted surface, and micro-patterned wetted surface applicable to spray cooling device

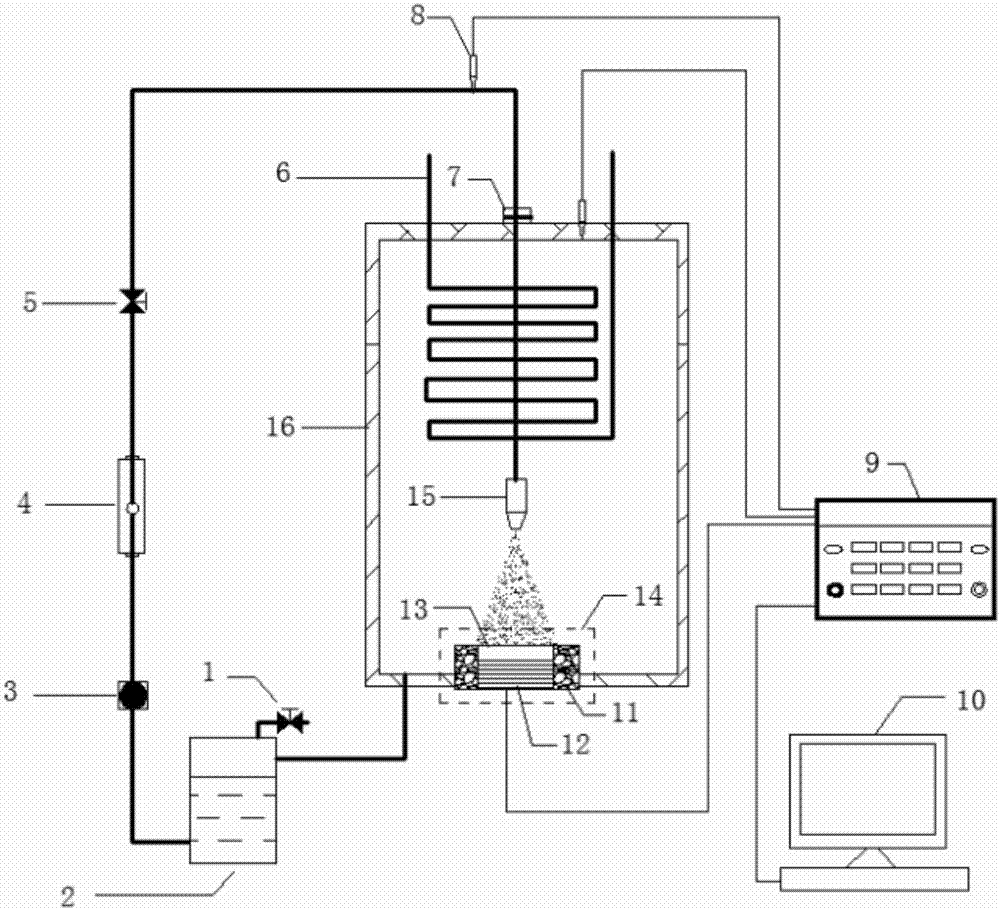

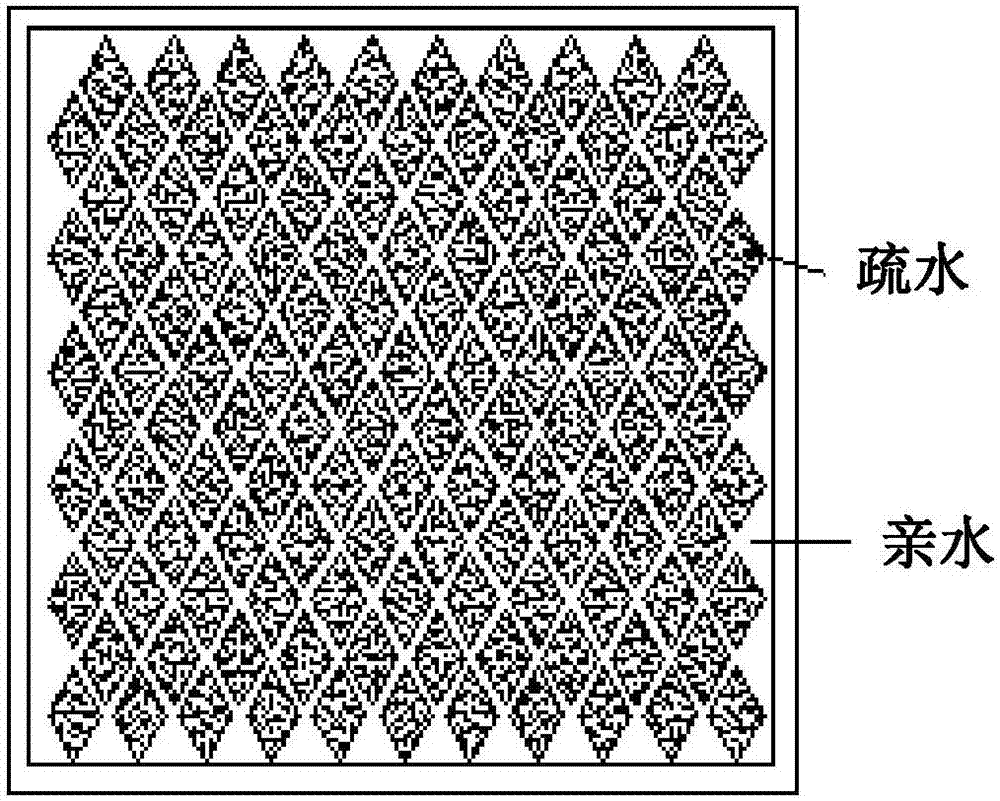

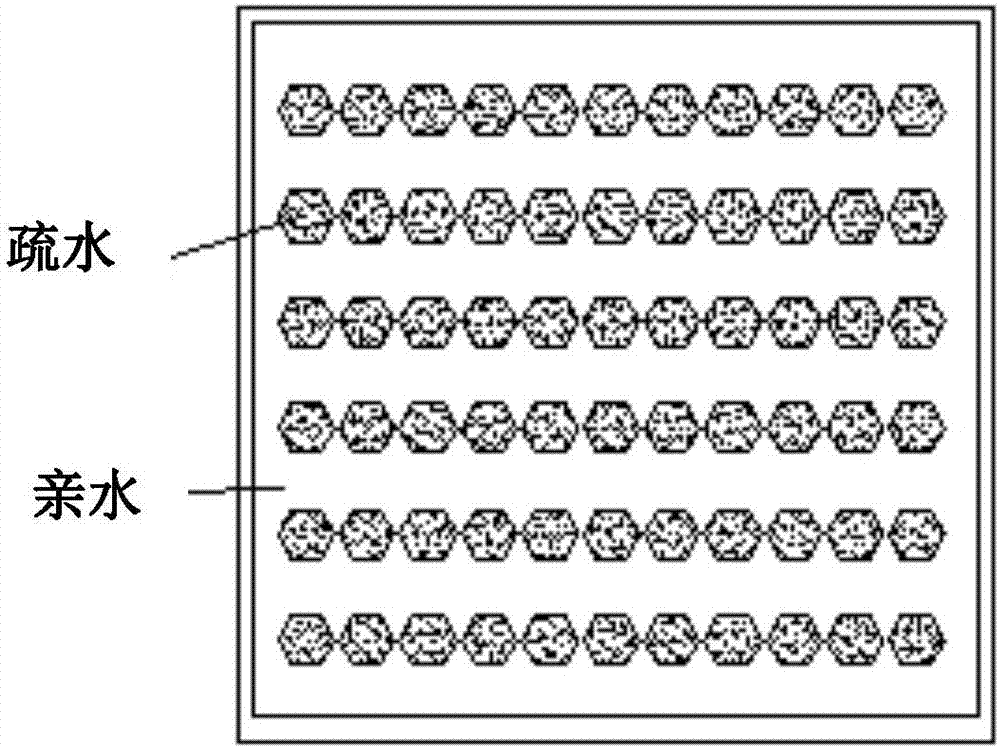

A technology of micro-patterning and spray cooling, which is applied in micro-structure devices, manufacturing micro-structure devices, processes for producing decorative surface effects, etc. Achieve the effect of reducing working fluid retention, increasing heat transfer rate, and preventing film boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Metal substrate cleaning: The polished pure titanium sheet (99.9%) was ultrasonically cleaned with acetone for 15 minutes, ethanol for 15 minutes, hydrochloric acid with a mass fraction of 15% for 15 minutes, and distilled water for 15 minutes. .

[0041] (2) Anodizing: Put the cleaned titanium sheet as the anode and the platinum sheet as the cathode into glycerol, H2 O (20vol%) and NH 4 F (1.0 wt%) in the electrolyte. In a constant temperature water bath at 30°C, under a voltage of 20V, anodize for 2 hours, and the boost rate is 0.1 V s -1 . After taking it out, rinse it repeatedly with deionized water, and place it in an oven at 80°C for 20 minutes.

[0042] (3) Annealing: Take the titanium sheet out of the oven and place it in a box-type resistance furnace for annealing at a heating rate of 5 °C min -1 , annealed at 300°C for 2h, and cooled naturally to room temperature.

[0043] (4) Hydrophobic treatment: Soak the annealed titanium sheet in n-hexane solutio...

Embodiment 2

[0047] (1) Metal substrate cleaning: The polished pure titanium sheet (99.9%) was ultrasonically cleaned with acetone for 15 minutes, ethanol for 15 minutes, hydrochloric acid with a mass fraction of 15% for 15 minutes, and distilled water for 15 minutes. .

[0048] (2) Anodizing: Put the cleaned titanium sheet as the anode and the platinum sheet as the cathode into glycerol, H 2 O (20vol%) and NH 4 F (1.0 wt%) in the electrolyte. In a constant temperature water bath at 20°C, under the voltage of 20V, anodize for 4h, and the boost rate is 0.1 V s -1 . After taking it out, rinse it repeatedly with deionized water, and place it in an oven at 80°C for 40 minutes.

[0049] (3) Annealing: Take the titanium sheet out of the oven and place it in a box-type resistance furnace for annealing at a heating rate of 5 °C min -1 , annealed at 300°C for 2h, and cooled naturally.

[0050] (4) Hydrophobic treatment: Soak the annealed titanium sheet in a n-hexane solution containing 4% tri...

Embodiment 3

[0054] (1) Metal substrate cleaning: The polished pure titanium sheet (99.9%) was ultrasonically cleaned with acetone for 15 minutes, ethanol for 15 minutes, hydrochloric acid with a mass fraction of 15% for 15 minutes, and distilled water for 15 minutes. .

[0055] (2) Anodizing: Put the cleaned titanium sheet as the anode and the platinum sheet as the cathode into glycerol, H 2 O (30vol%) and NH 4 F (2.0 wt%) in the electrolyte. In a constant temperature water bath at 30°C, under the voltage of 40V, anodize for 2 h, and the boost rate is 0.1 V s -1 . After taking it out, rinse it repeatedly with deionized water, and place it in an oven at 120°C for 30 minutes.

[0056] (3) Annealing: Take the titanium sheet out of the oven and place it in a box-type resistance furnace for annealing at a heating rate of 5 °C min -1 , annealed at 400 ° C for 1 h, and cooled naturally.

[0057] (4) Hydrophobic treatment: Soak the annealed titanium sheet in n-heptane solution containing oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com