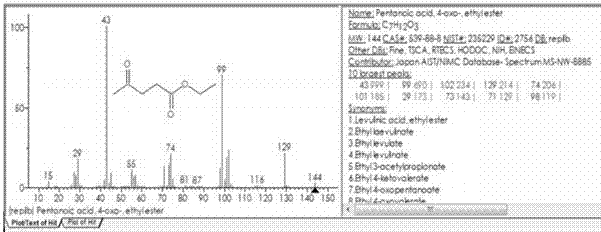

Method for preparing ethyl levulinate from deoxyribose

A technology of ethyl levulinate and deoxyribose, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as increased cost and complicated process, and achieves improved production efficiency and method. Simple, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

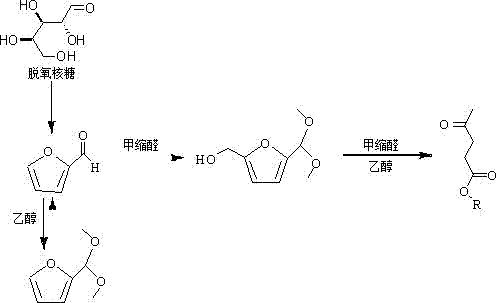

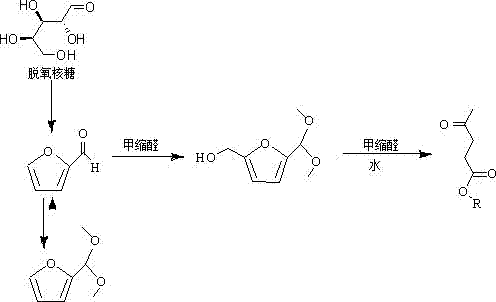

Method used

Image

Examples

Embodiment 1

[0028] Add 1.8g deoxyribose, 3.6g cation exchange resin 70, and 40ml methylal to the reactor at room temperature and mix, so that the deoxyribose is completely dissolved in the solvent, and purify the reactor three times with high-purity nitrogen to remove the Residual gas was present, followed by heating to 130° C. within 10 minutes and stirring for 2 hours to yield the product.

Embodiment 2

[0030] Add 10.8g of deoxyribose, 4.0g of cation exchange resin 70, and 80ml of methylal into the reactor respectively, so that the deoxyribose is completely dissolved in the solvent, and then heated to 140°C within 10 minutes and stirred for 2 hours to obtain levulinic acid Ethyl ester product; Wherein, stirring speed is 600rpm.

Embodiment 3

[0032] Add 1.8g of deoxyribose, 3.6g of cation exchange resin 70, and 40ml of formal into the reactor respectively, so that the deoxyribose is completely dissolved in the solvent, and then heated to 150°C within 10 minutes and stirred for 2 hours to obtain levulinic acid Ethyl ester product; Wherein, stirring speed is 600rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com