Method for preparing rodlike fluorescent labeled microplastics

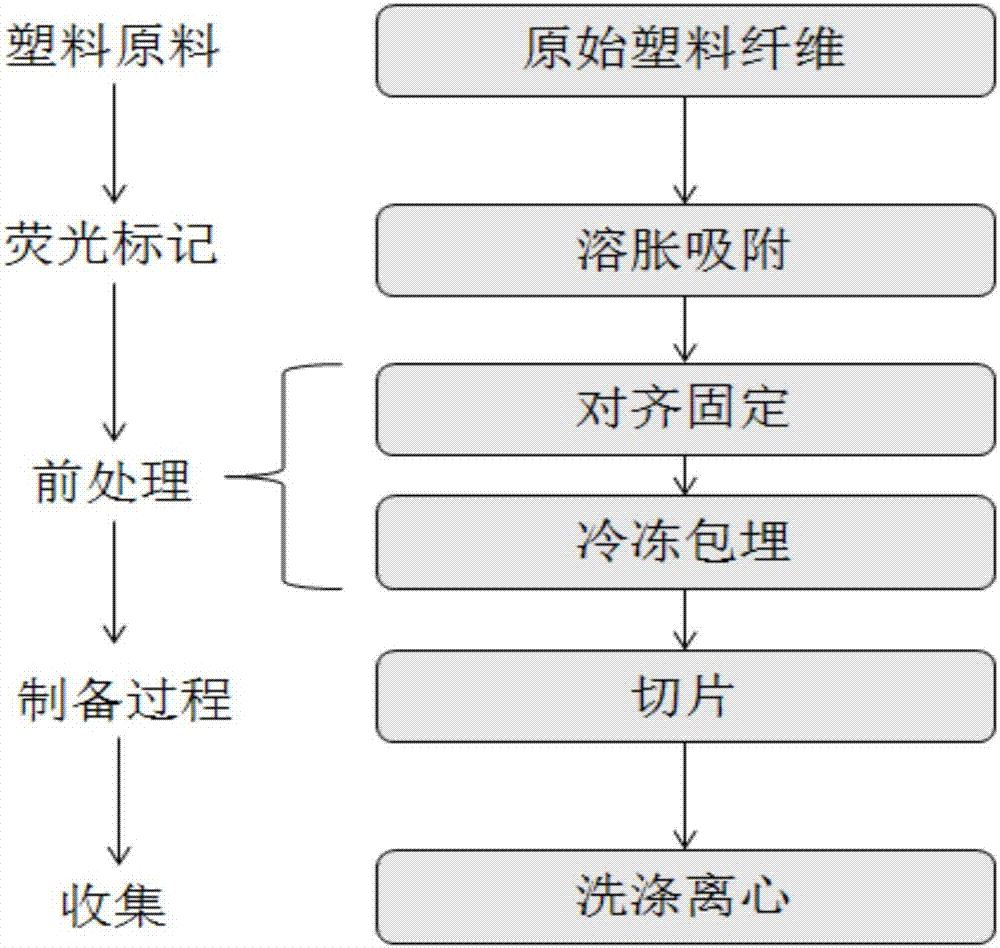

A technology of fluorescent labeling and microplastics, applied in the preparation of test samples, analysis of materials, sampling, etc., can solve the problem that plastic microspheres with uniform shape cannot simulate microplastics well, and achieve uniform shape and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of rod-shaped polystyrene fluorescently labeled microplastics:

[0036] (1) Dissolve Nile Red dye in acetone to prepare a 2.5 g / L stock solution of Nile Red dye. Use a 5 mL centrifuge tube to mix the Nile red dye stock solution with n-hexane at a volume ratio of 1:4. Add unlabeled polystyrene fibers into the mixture, vortex and let stand for 24 h, use a pipette gun to carefully absorb the mixture, and wash three times with ultrapure water to obtain fluorescently labeled polystyrene fibers.

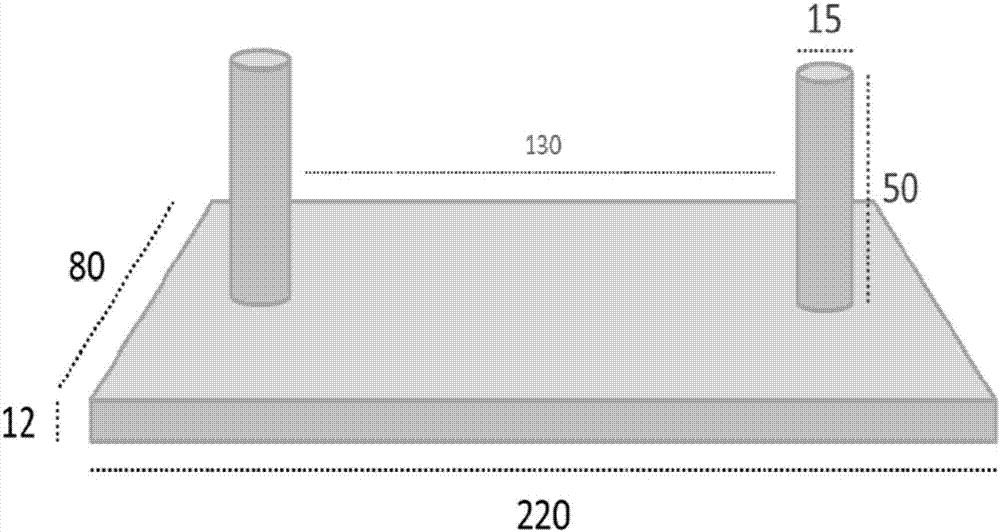

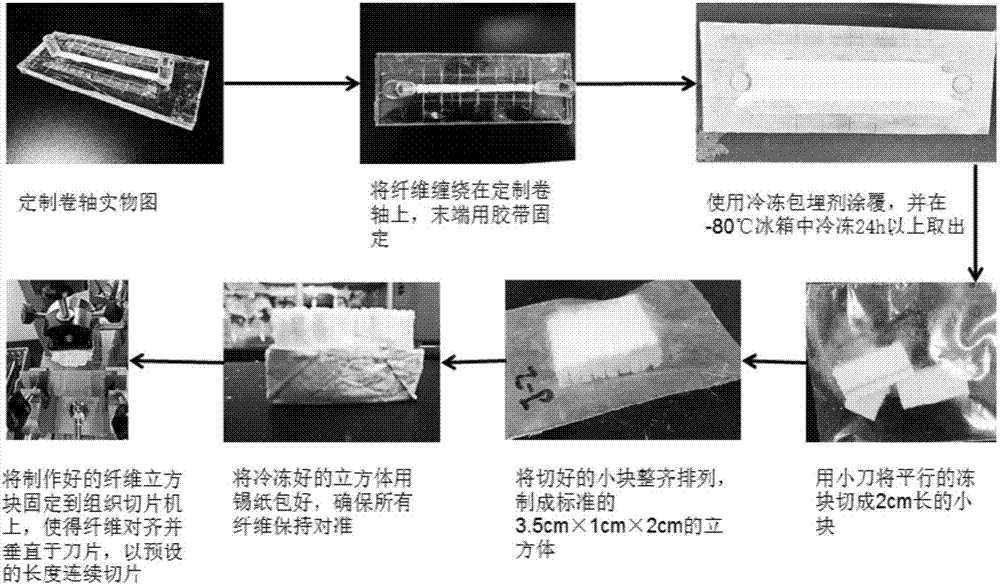

[0037] (2) Fluorescently labeled polystyrene fibers are wound on custom-made spools (such as figure 2 shown) come up to align the fibers and the ends are taped as image 3 .

[0038] (3) Coat the aligned fibers with frozen embedding agent and freeze them in a -80°C refrigerator for 26 hours to fix and make the fibers brittle. Use a knife to cut the frozen block into 2cm-long parallel pieces, and arrange 8 of them neatly to make a standard 3.5cm×1cm×2cm cube, wrap it...

Embodiment 2

[0042] Preparation of rod-shaped polypropylene fluorescently labeled microplastics:

[0043] (1) Dissolve Nile Red dye in acetone to prepare a 3 g / L stock solution of Nile Red dye. Use a 5 mL centrifuge tube to mix the Nile red dye stock solution with n-hexane at a volume ratio of 1:3. Add unlabeled polypropylene fibers into the mixture, vortex and let stand for 36 h, use a pipette gun to carefully absorb the mixture, and wash 4 times with ultrapure water to obtain fluorescently labeled polypropylene fibers.

[0044] (2) Fluorescently labeled polypropylene fibers are wound on custom-made spools (such as figure 2 shown) up to align the fibers and the ends are secured with tape.

[0045] (3) Coat the aligned fibers with frozen embedding agent and freeze them in a -60°C refrigerator for 26 hours to fix and make the fibers brittle. Use a knife to cut the frozen block into 2cm-long parallel pieces, and arrange 9 of them neatly to make a standard 3.5cm×1cm×2cm cube, wrap it in t...

Embodiment 3

[0049] Preparation of rod-shaped polyethylene fluorescently labeled microplastics:

[0050] (1) Dissolve Nile Red dye in acetone to prepare a 5 g / L stock solution of Nile Red dye. Use a 5 mL centrifuge tube to mix the Nile red dye stock solution with n-hexane at a volume ratio of 1:2. Add unlabeled polyethylene fibers into the mixture, vortex and let stand for 48 h, use a pipette gun to carefully absorb the mixture, and wash 5 times with ultrapure water to obtain fluorescently labeled polyethylene fibers.

[0051] (2) Fluorescently labeled polyethylene fibers are wound on custom-made spools (such as figure 2 shown) up to align the fibers and the ends are secured with tape.

[0052] (3) Coat the aligned fibers with frozen embedding agent and freeze them in a -40°C refrigerator for 26 hours to fix and make the fibers brittle. Use a knife to cut the frozen block into 2cm-long parallel pieces, and arrange 10 of them neatly to make a standard 3.5cm×1cm×2cm cube, wrap it in tin fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional diameter | aaaaa | aaaaa |

| Wheelbase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com