Calculus preventing compound premixed feed lick brick for rams

A technology of pre-mixed feed and licking bricks is applied in the direction of animal feed, animal feed, and animal feed molding or processing, which can solve the problem that the nutrition and trace element needs of rams cannot be well met, and achieve the prevention of ram urine. Stones, nutrient-rich, promotes rapid weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

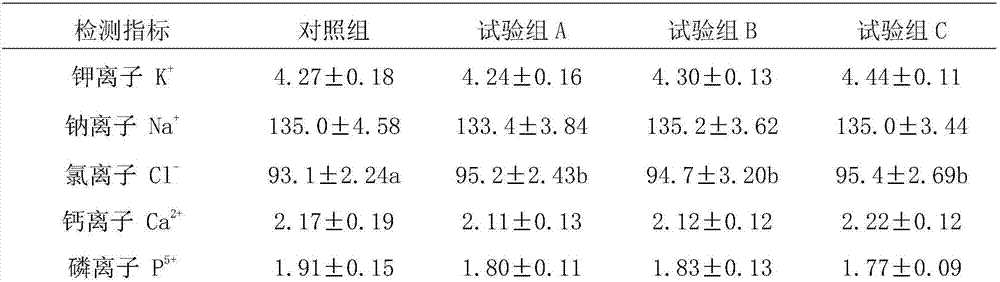

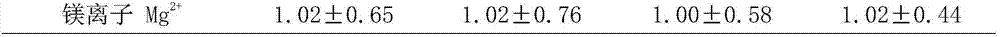

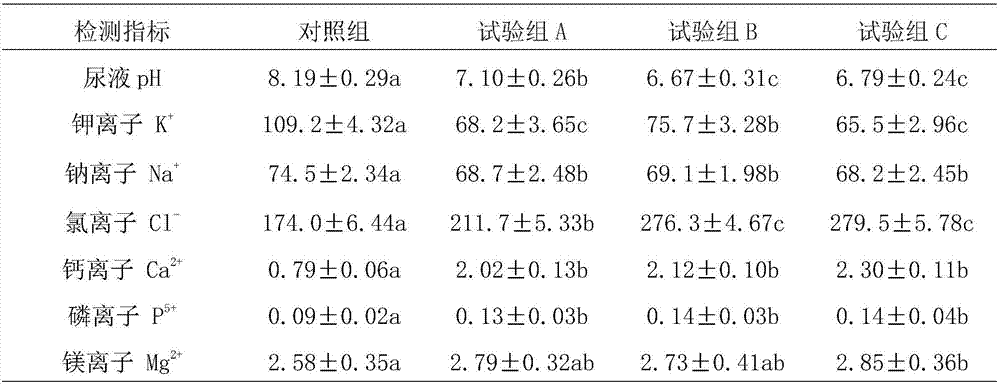

Examples

Embodiment 1

[0026] Produce licking brick A according to the following method:

[0027] Proportioning raw materials according to the following formula: 50% of salt, 6% of cement, 8% of bentonite, 6% of ammonium chloride, 8% of baking soda containing 45.96% of sodium by mass, 2% of calcium formate containing 30% of calcium by mass, fragrance 0.05% potassium chloride, 6% potassium chloride containing 51% potassium by mass, 10% calcium hydrogen phosphate containing 24.58% phosphorus by mass, 0.3% ferrous sulfate containing 30% iron by mass, 25% copper by mass 0.1% of copper sulfate, 0.3% of zinc sulfate containing 34.5% by mass of zinc, 0.7% of magnesium sulfate containing 15% by mass of magnesium, 0.15% of manganese sulfate containing 31.8% of manganese by mass, selenium containing 0.2% by mass of selenium Sodium Oxide 0.05%, cobalt chloride 0.05% with cobalt mass ratio 1.24%, calcium iodate 0.3% with iodine mass ratio 1.24%, rumenin 1%, compound multidimensional 1%; Composition of each com...

Embodiment 2

[0033]Produce licking brick B according to the following method:

[0034] Proportioning raw materials according to the following formula: 55% of salt, 7.6% of cement, 10% of bentonite, 4.5% of ammonium chloride, 6% of baking soda containing 45.96% of sodium by mass, 1.5% of calcium formate containing 30% of calcium by mass, fragrance 0.04% potassium chloride, 4% potassium chloride containing 51% potassium by mass, 8% calcium hydrogen phosphate containing 24.58% phosphorus by mass, 0.25% ferrous sulfate containing 30% iron by mass, 25% copper by mass 0.08% copper sulfate, 0.25% zinc sulfate containing 34.5% by mass of zinc, 0.5% of magnesium sulfate containing 15% by mass of magnesium, 0.12% of manganese sulfate containing 31.8% by mass of manganese, and selenium containing 0.2% by mass of selenium Sodium Oxide 0.03%, cobalt chloride 0.04% with cobalt mass ratio 1.24%, calcium iodate 0.34% with iodine mass ratio 1.24%, rumenin 0.8%, compound multidimensional 0.95%; Composition...

Embodiment 3

[0040] Produce licking brick C according to the following method:

[0041] Proportioning raw materials according to the following formula: 46% of salt, 4% of cement, 6% of bentonite, 8% of ammonium chloride, 8.5% of baking soda containing 45.96% of sodium by mass, 2.5% of calcium formate containing 30% of calcium by mass, fragrance 0.03% potassium chloride, 8% potassium chloride containing 51% potassium by mass, 12% calcium hydrogen phosphate containing 24.58% phosphorus by mass, 0.4% ferrous sulfate containing 30% iron by mass, 25% copper by mass 0.15% of copper sulfate, 0.4% of zinc sulfate containing 34.5% by mass of zinc, 0.8% of magnesium sulfate containing 15% by mass of magnesium, 0.2% of manganese sulfate containing 31.8% of manganese by mass, selenium containing 0.2% by mass of selenium Sodium Oxide 0.06%, Cobalt Chloride 0.06% containing Cobalt Mass Ratio 1.24%, Calcium Iodate 0.4% Containing Iodine Mass Ratio 1.24%, Rumenin 1.5%, Compound Multidimensional 1.2%; Said...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com