Sugar-free fruit product with fortified calcium and zinc nutrition, and production technology thereof

A fruit product, zinc nutrition technology, applied in food science, animal feed, additional food elements, etc., can solve the problems of incomplete nutrition and high sugar content, and achieve the effects of short processing time, good taste and unique fruit fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of Sugar Free, Calcium Fortified Strawberry Jam

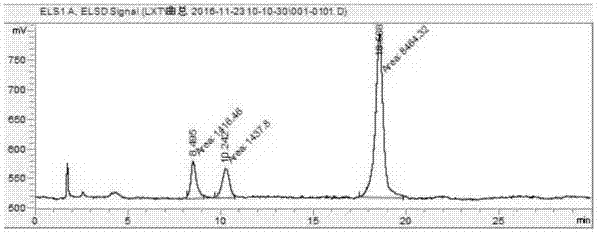

[0030] 1) Fresh strawberries were washed and beaten, mixed with aqueous solution at a ratio of 1:1.5 (m / v), stirred at 40°C for 30 minutes, added acetic acid sodium acetate buffer solution to adjust the pH to 5.5, and samples were taken for HPLC to obtain enzyme treatment The HPLC spectrum of the sugar content in the pulp dilution before ( figure 1 ).

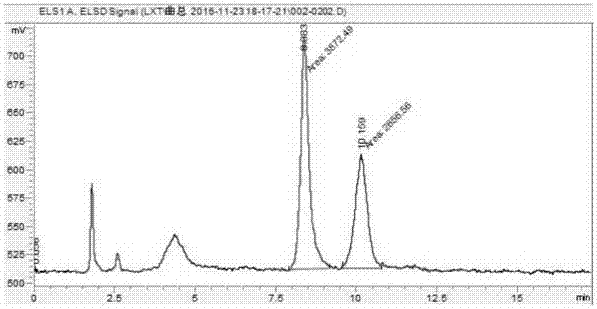

[0031] (2) To detect the content of reducing sugar in the diluent, add 180IU sucrase per gram of reducing sugar, add sucrase, react at 50°C for 15 minutes, take samples for HPLC, and obtain the HPLC spectrum of sugar content in the pulp dilution after hydrolysis by sucrase ( figure 2 ).

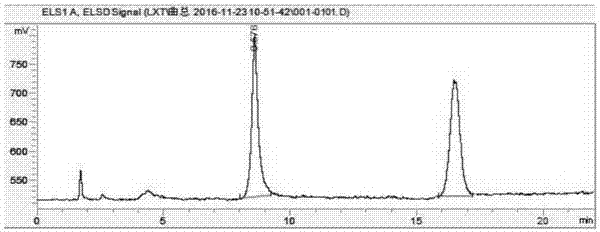

[0032] Then, add glucose oxidase enzyme in the amount of 250IU glucose oxidase per gram of reducing sugar, and at the same time pass oxygen into the reaction system under the condition of sufficient stirring, the oxygen flow rate is 0.2L / h*L, and continue the re...

Embodiment 2

[0035] Example 2: Preparation of sugar-free, zinc-fortified banana juice

[0036](1) Take fresh banana pulp, wash it, beat it, mix it with aqueous solution at a ratio of 1:1.5 (m / v), stir at 40°C for 30 minutes, add acetic acid sodium acetate buffer solution to adjust the pH to 5.5, and take samples for HPLC detection.

[0037] (2) To detect the content of reducing sugar in the diluent, add 180 IU of sucrase per gram of reducing sugar, react at 50°C for 15 minutes, and sample for HPLC detection.

[0038] Then, add glucose oxidase enzyme in the amount of 250IU glucose oxidase per gram of reducing sugar, and at the same time pass oxygen into the reaction system under the condition of sufficient stirring, the oxygen flow rate is 0.2L / h*L, and continue the reaction at 50°C .

[0039] (3) After continuing the oxygenation reaction for 15 minutes, add zinc chloride solution, maintain the conditions of 50°C and full stirring, and check the pH value. The gluconic acid produced by gluc...

Embodiment 3

[0041] Embodiment 3: HPLC chromatographic conditions and parameters

[0042] The chromatographic column is a shodex sugar column, the flow rate is 1.2 mL / min, the mobile phase is acetonitrile:water=30:70 (v:v), the injection volume is 5 μL, the column temperature is 35°C, and the carrier gas flow rate is 2.0 mL / min , The atomization temperature is 70°C, and the evaporation temperature is 100°C.

[0043] Preliminary experiments were carried out with glucose, fructose, and sucrose standard substances, and the results showed that the linear relationship between the three substances was good within the range of 50mg / kg-5000mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com