Method for improving catalytic selectivity of metal nanoparticle/porous coordination polymer composite catalyst and application thereof

A technology of metal nanoparticles and composite catalysts, applied in the direction of organic compound/hydride/coordination complex catalysts, carbon compound catalysts, physical/chemical process catalysts, etc., can solve the problem of reducing catalytic selectivity and difficult metal nanoparticles Problems such as the interior of the porous coordination polymer and the limitation of the preparation scale can achieve the effects of improving catalytic selectivity, improving chemical reaction site selectivity, and improving molecular size selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of the ZIF-8 nanoparticle that size is 100~200nm

[0033]Reported methods were followed with modifications during preparation. Add zinc nitrate hexahydrate (2.08 g, 7 mmol) and 100 mL 99% methanol into a 250 mL screw-top glass bottle, and stir vigorously to completely dissolve the zinc nitrate. 100 mL of a methanol solution containing 2-methylimidazole (2.01 g, 24.5 mmol) was quickly added under vigorous stirring. The mixed solution was vigorously stirred at room temperature of 25-30° C. for 20 h. The fully reacted reaction mixture was evenly transferred to eight 50mL centrifuge tubes, centrifuged at 7000rpm for 5min, the supernatant was removed, and the white ZIF-8 solid was collected. The solids in each centrifuge tube were then washed 4 times with 25 mL of methanol. The resulting white solid was collected and dried in a vacuum desiccator at 25-30° C. for 12 h at room temperature. The obtained product was characterized by powder X-ray...

Embodiment 2

[0034] Embodiment 2: the preparation of Pt / ZIF-8 composite catalyst

[0035] Example 1 The Pt / ZIF-8 composite was prepared by the traditional impregnation method, washed with 30 mL of methanol for 5 times, and then dried in a vacuum desiccator at room temperature of 25-30°C for 12 hours. The resulting product has characterized its material structure and morphology by powder X-ray diffraction (PXRD) and transmission electron microscopy (TEM), and the content of Pt in the sample obtained by inductively coupled plasma (ICP) has been determined to be 1.88wt% (mass score ratio).

Embodiment 3

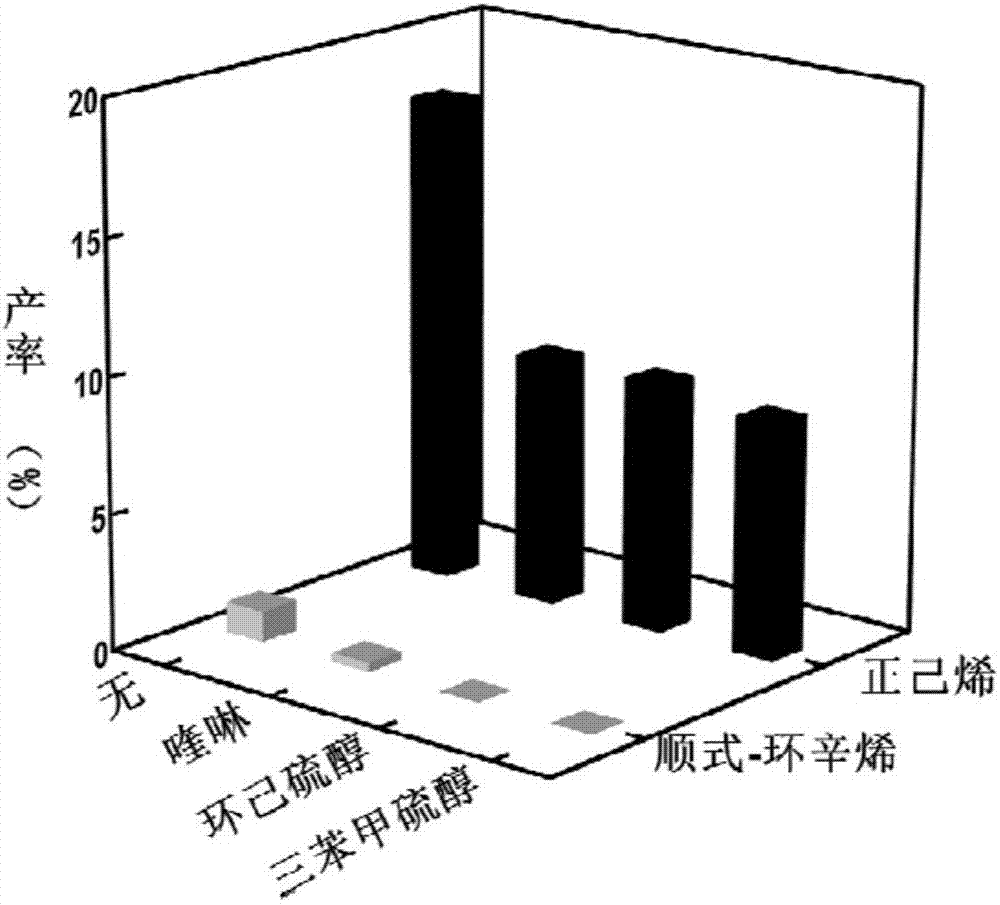

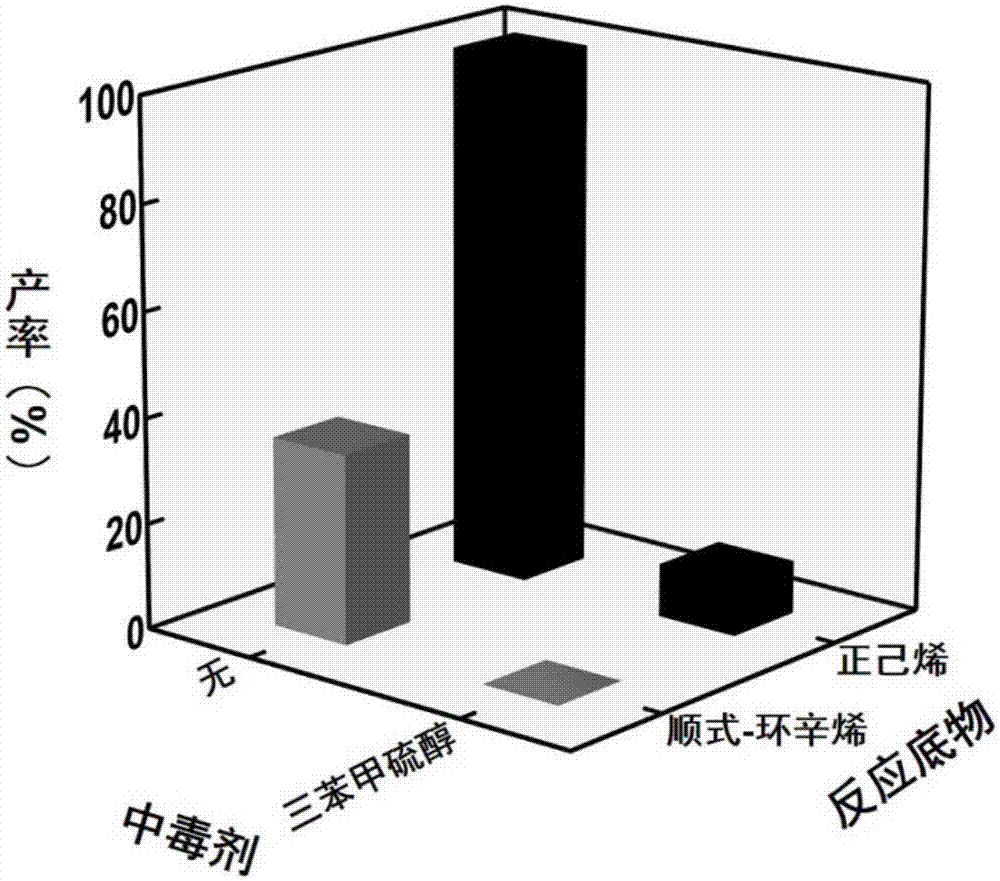

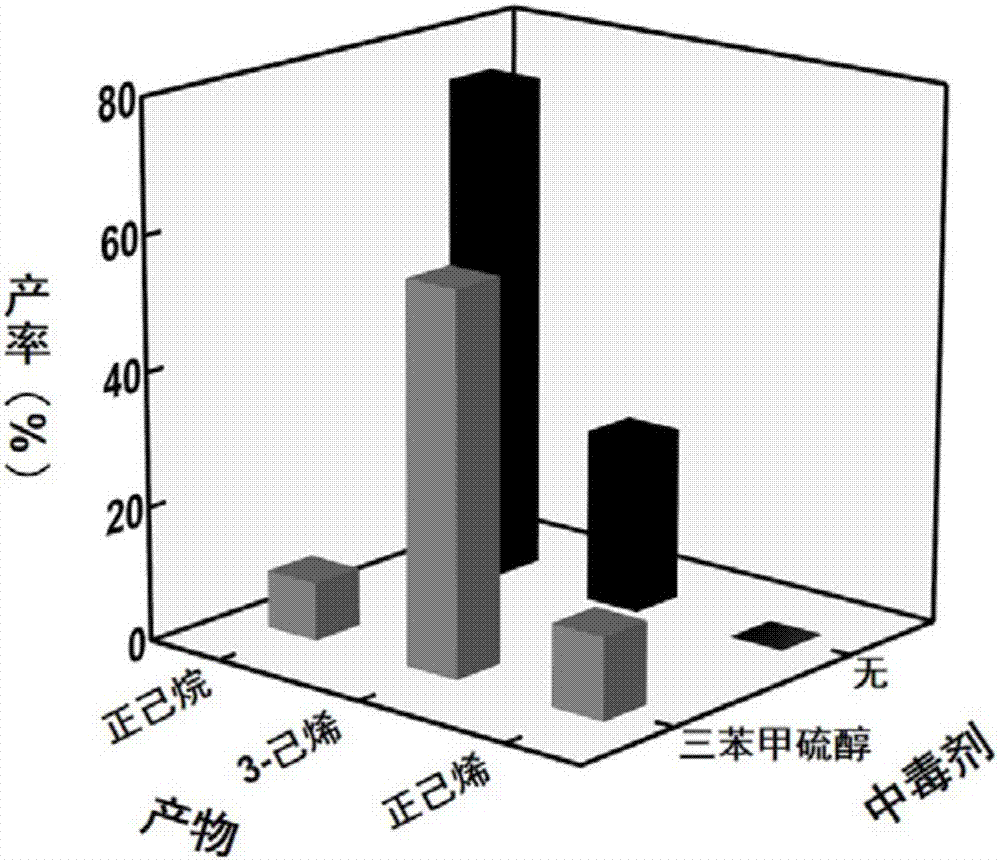

[0036] Embodiment 3: the application of Pt / ZIF-8 composite catalyst in the catalytic hydrogenation reaction of olefin

[0037] The Pt / ZIF-8 composite catalyst prepared in Example 2 was pre-vacuum-dried at 120° C. for 12 hours to be activated. Add the activated Pt / ZIF-8 composite catalyst (20 mg) and a magnetic stirring bar into a 5 mL glass bottle, and seal the glass bottle with a silica gel stopper. Use a vacuum pump to pump out the gas in the bottle, then inject pure hydrogen, and repeat this operation 5 times. Use a syringe to inject 2 mL of ethyl acetate solution containing or not containing poisoning agent (i.e. passivating agent), and the poisoning agent and its dosage are shown in Table 1: quinoline (100 μL), cyclohexanethiol (0.1 μL) , Trityl mercaptan (1 mg). The mixture was ultrasonically dispersed in a water bath at 30 °C for 10 min, and then stirred at room temperature at 25 °C for 1 h. Inject 1 mL of ethyl acetate solution containing n-hexene (62.5 μL) or cis-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com