Preparation method and application of palladium supported catalyst for methanol catalytic combustion

A catalytic combustion, palladium-supported technology is applied in the field of preparation of palladium-supported catalysts, which can solve the problems of high consumption of precious metals, easy carbon deposition of catalysts, poor stability, etc., and achieves improved catalytic activity and selectivity, excellent catalytic activity, and maintenance of catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

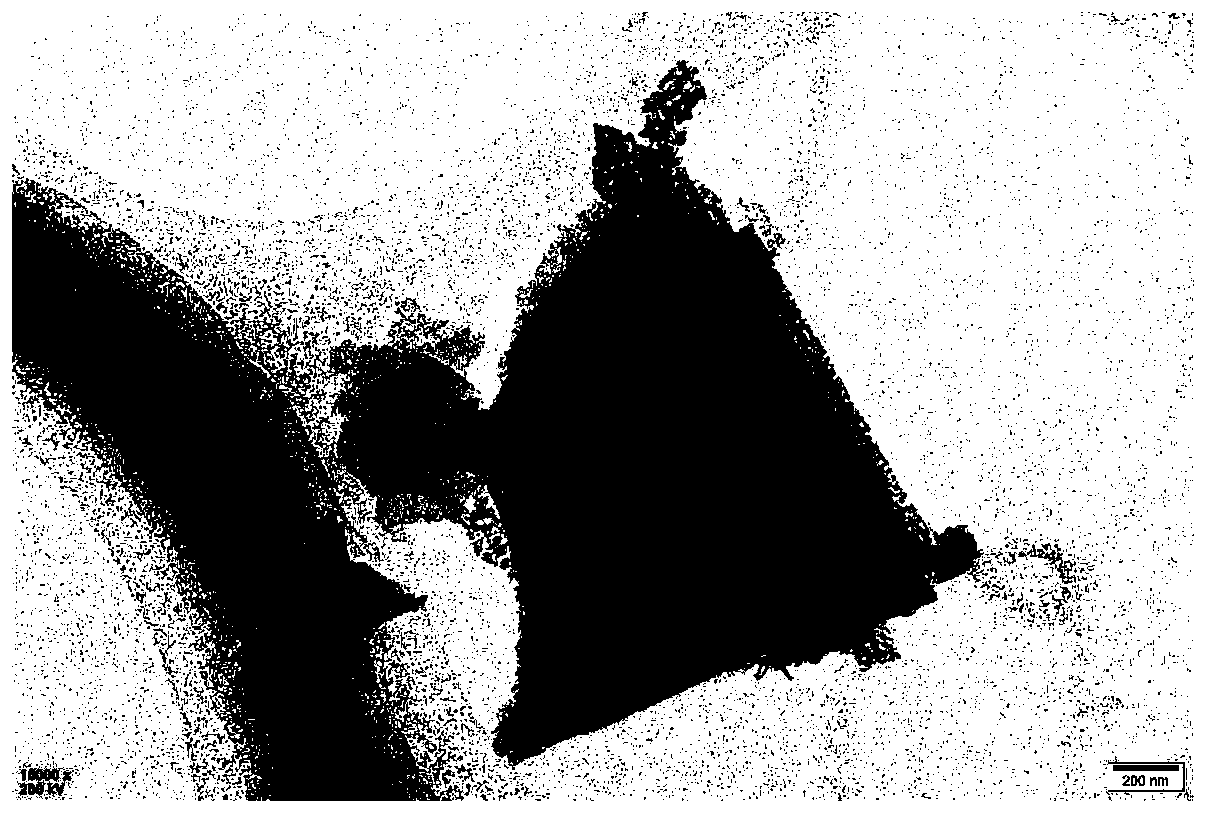

Image

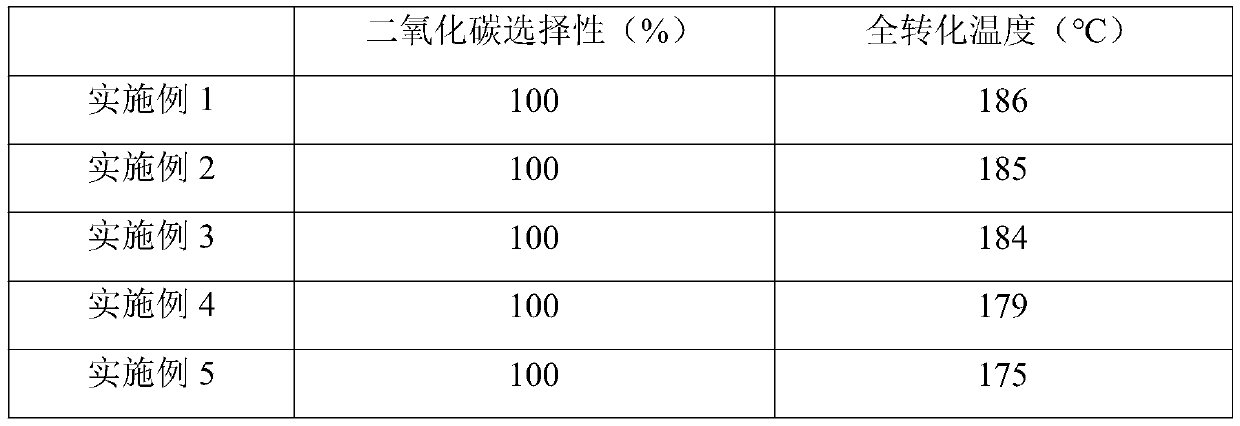

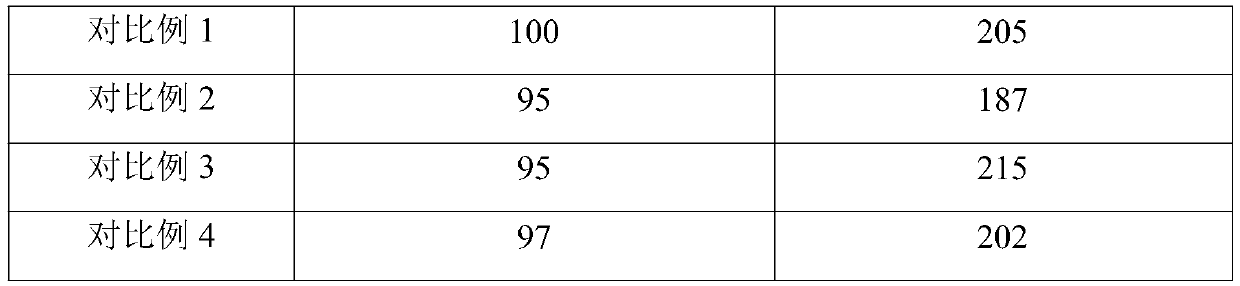

Examples

Embodiment 1

[0026] Embodiment 1 is used for the preparation method of the palladium supported catalyst of methanol catalytic combustion

[0027] Specifically include the following steps:

[0028] (1) Pour palladium nitrate (the content of palladium is 0.05g), manganese nitrate (the content of manganese is 0.50g), aluminum oxide (9.45g) and 30mL deionized water are poured into the flask and mixed uniformly to obtain a mixed solution, which will be obtained The mixed solution is placed in a rotary evaporator, and the temperature is 80 ° C and the vacuum is 0.1 MPa, and the solvent is removed to obtain a solid;

[0029] (2) Mix the solid obtained in step (1) with sodium dihydrogen phosphate (the mass ratio of solid to sodium dihydrogen phosphate is 10:1), and then roast them sequentially (the roasting atmosphere is air, the temperature is 300°C, and the time is 1h;) and reduction (reducing atmosphere is 10% H 2 / Ar mixed gas, the temperature is 100°C, and the time is 0.5h. ), promptly obt...

Embodiment 2

[0030] Embodiment 2 is used for the preparation method of the palladium supported catalyst of methanol catalytic combustion

[0031] Specifically include the following steps:

[0032] (1) Pour palladium nitrate (the content of palladium is 0.10g), manganese nitrate (the content of manganese is 1.00g), aluminum oxide (8.90g) and 30mL deionized water are poured into the flask and mixed uniformly to obtain a mixed solution. The mixed solution is placed in a rotary evaporator, and the temperature is 80 ° C and the vacuum is 0.1 MPa, and the solvent is removed to obtain a solid;

[0033] (2) Mix the solid obtained in step (1) with sodium dihydrogen phosphate (the mass ratio of solid to sodium dihydrogen phosphate is 15:1), and then roast them sequentially (the roasting atmosphere is air, the temperature is 500°C, and the time is 3h;) and reduction (reducing atmosphere is 10% H 2 / Ar mixed gas, the temperature is 200°C, and the time is 1.5h. ), promptly obtain described palladium...

Embodiment 3

[0034] Embodiment 3 is used for the preparation method of the palladium supported catalyst of methanol catalytic combustion

[0035] Specifically include the following steps:

[0036] (1) Pour palladium nitrate (the content of palladium is 0.06g), manganese nitrate (the content of manganese is 0.70g), aluminum oxide (9.24g) and 30mL deionized water are poured into the flask and mixed uniformly to obtain a mixed solution, which will be obtained The mixed solution is placed in a rotary evaporator, and the temperature is 80 ° C and the vacuum is 0.1 MPa, and the solvent is removed to obtain a solid;

[0037] (2) Mix the solid obtained in step (1) with sodium dihydrogen phosphate (mass ratio of 12:1), and then perform roasting (the roasting atmosphere is air, the temperature is 400°C, and the time is 2h;) and reduction (reduction The atmosphere is 10% H 2 / Ar mixed gas, the temperature is 150°C, and the time is 1h. ), promptly obtain described palladium supported catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com