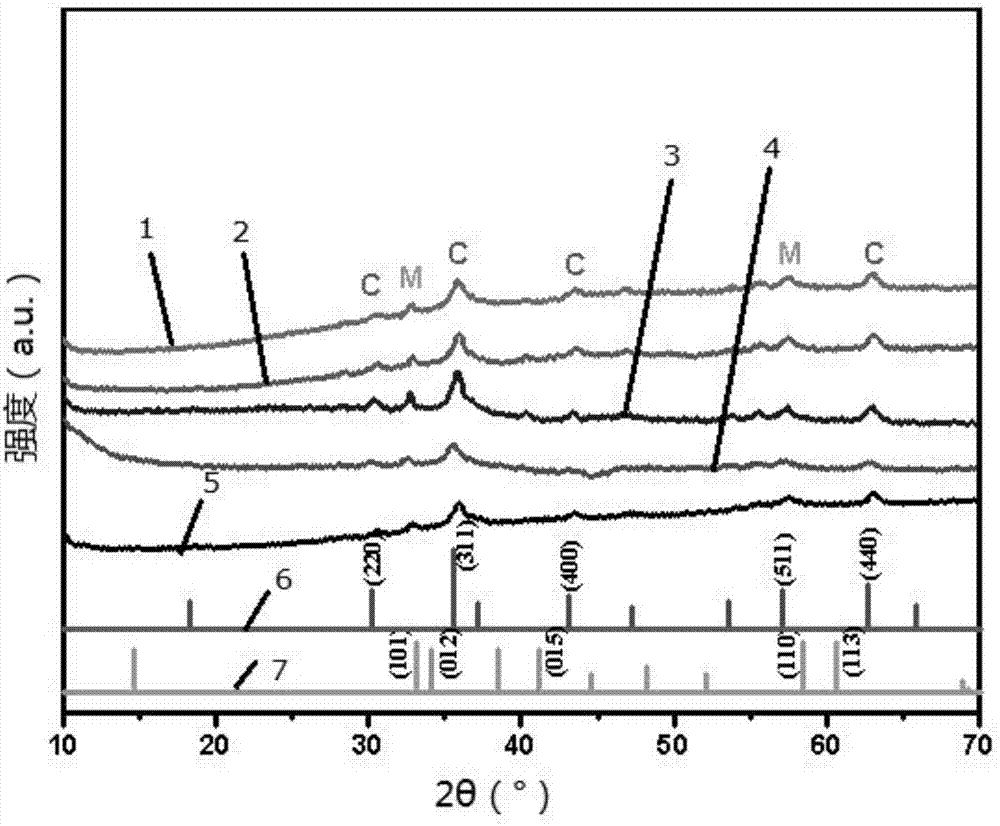

Preparation method and application of Z-type magnetic nanocomposite MoS2/CoFe2O4 photocatalyst

A technology of cobalt tetraoxoferrate and composite materials, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of catalyst recovery difficulties, waste, etc., and achieve improved photodegradation ability, The effect of increasing the number of cycles and increasing the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

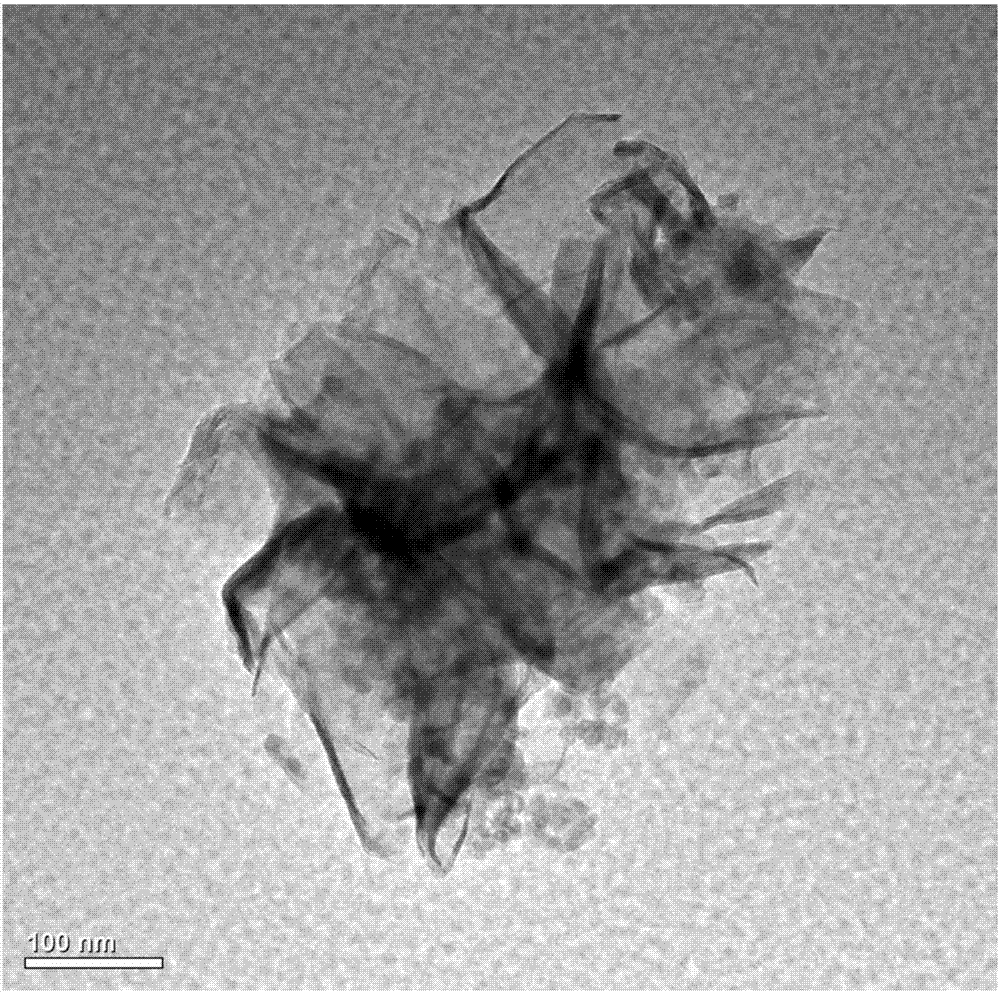

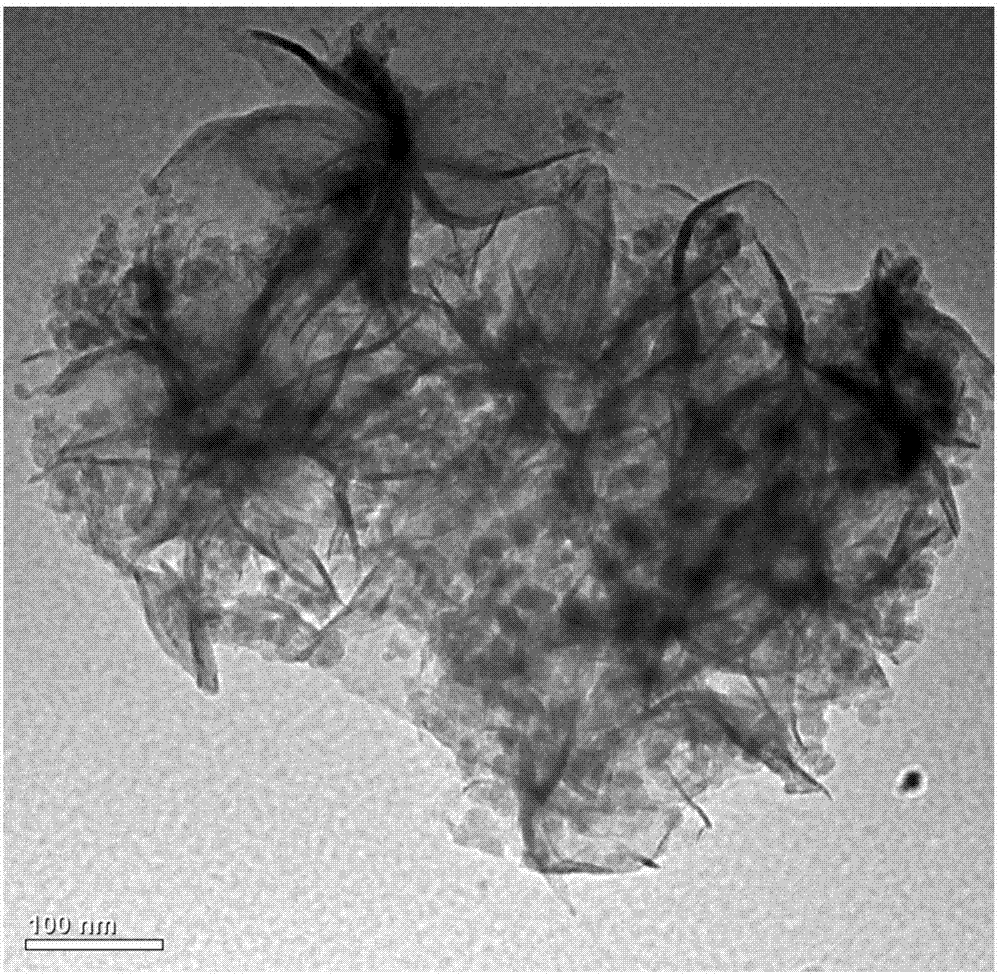

[0020] Specific embodiment one: the preparation method of a kind of Z-type magnetic nanocomposite molybdenum disulfide / cobalt ferrite photocatalyst of the present embodiment is specifically carried out according to the following steps:

[0021] 1. FeCl 3 ·6H 2 O and CoCl 2 ·6H 2 O is dispersed in ethylene glycol solution, and magnetically stirred for 8-15 minutes to obtain a clear mixed solution; then sodium acetate and polyethylene glycol are added to the clear mixed solution, continued magnetically stirred for 20-40 minutes, and then transferred to polytetrafluoroethylene In the liner, react at a temperature of 180-220°C for 8-12 hours, then cool naturally to room temperature, and use a magnet to separate and collect the black precipitate CoFe 2 o 4 , will black precipitate CoFe 2 o 4 First wash with deionized water for 3 to 5 times and then with ethanol for 3 to 5 times, and dry at a temperature of 50°C for 10 to 14 hours to obtain CoFe 2 o 4 powder; the FeCl 3 ·6H...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the FeCl described in step one 3 ·6H 2 O and CoCl 2 ·6H 2 The molar ratio of O is 1:0.5. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass ratio of polyethylene glycol and sodium acetate described in step one is 1:3.5. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com