High-ammonia-nitrogen sewage treatment circulating pool and sewage treatment device and process with circulating pool

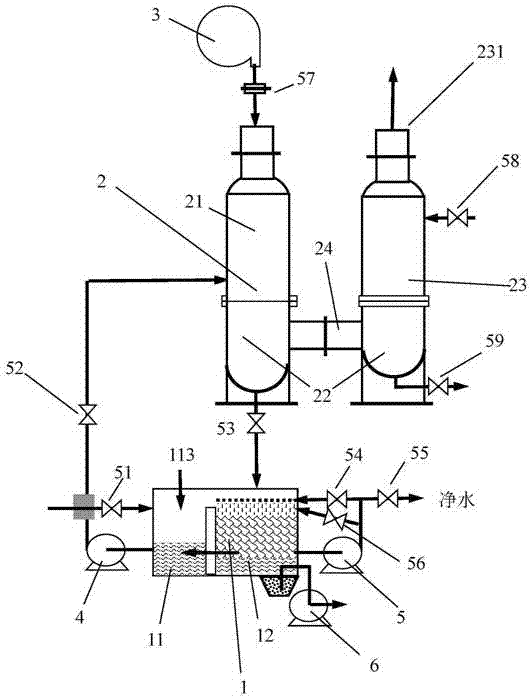

A sewage treatment device, sewage treatment technology, applied in water/sewage treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of short residence time, reduced mass transfer driving force, and inoperable system and other problems to achieve the effect of reducing the floor space, increasing the mechanical strength, and improving the technical content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

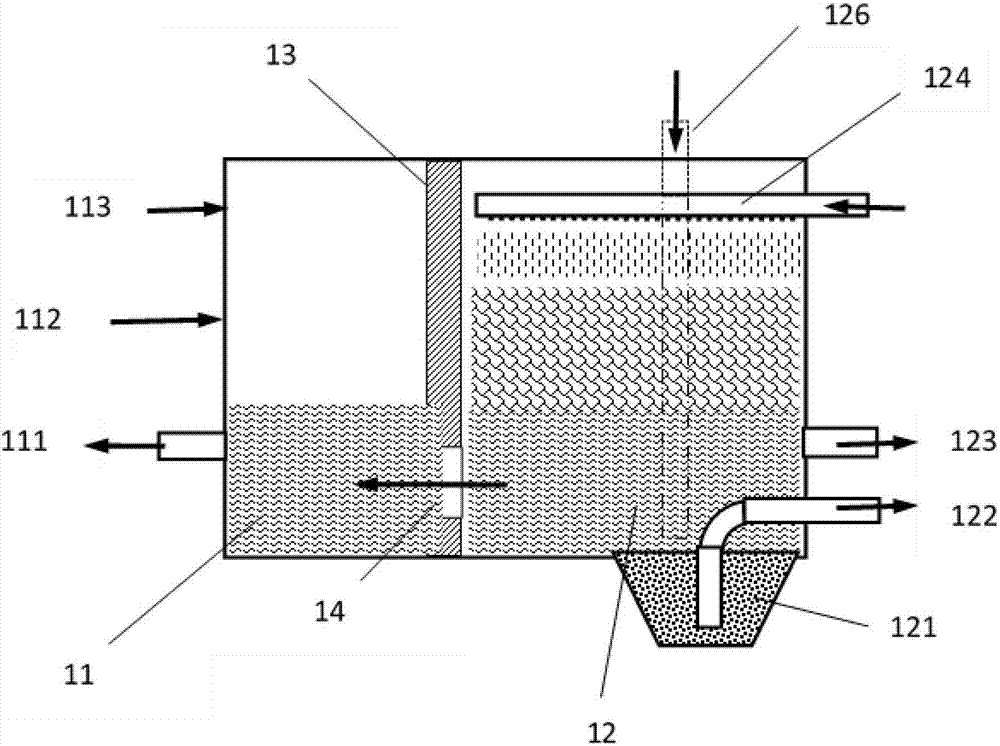

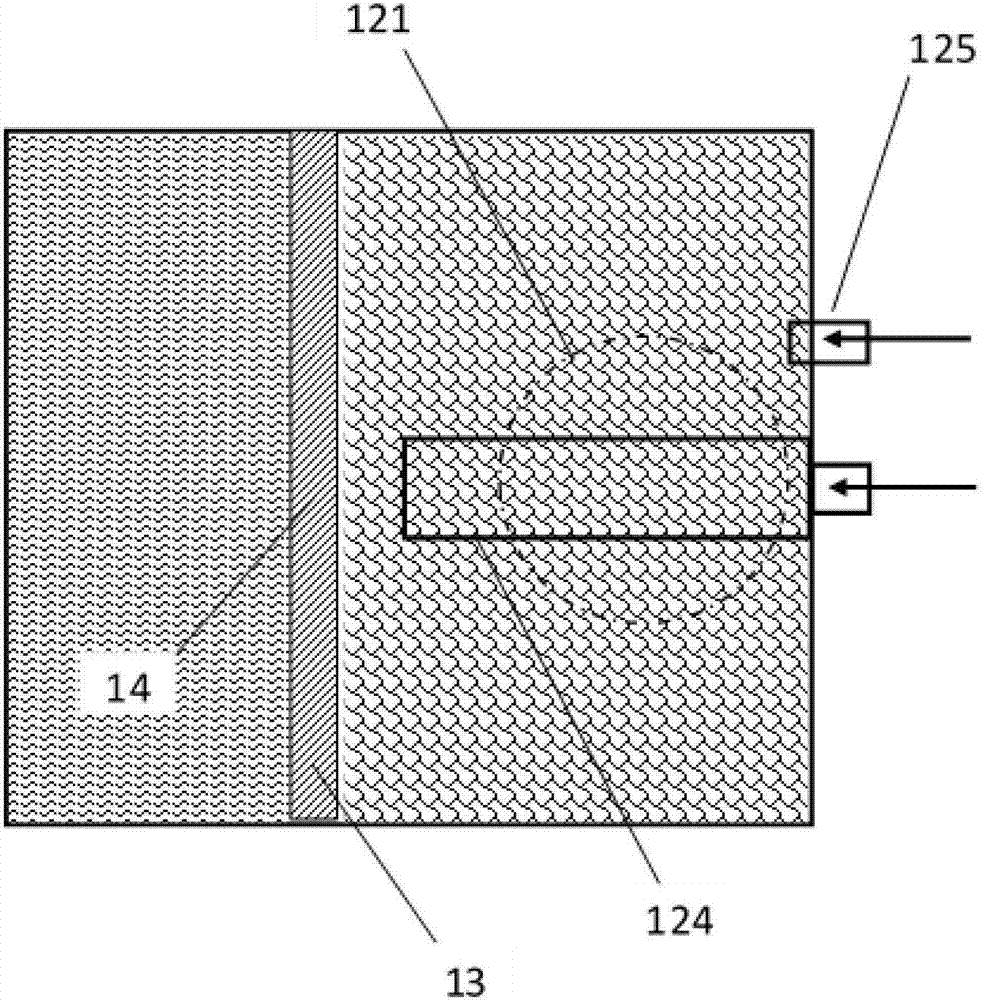

[0029] Biopharmaceutical wastewater treatment of a Hunan Biotechnology Co., Ltd. This project adopts the comprehensive sewage treatment process of "rotary foam separation method at room temperature denitrification + tail gas deep purification + biochemical treatment (including oxidation pond)". In this project, a sewage circulation pool is configured 10m 3 . The sewage treatment circulation pond comprises a sewage pond 11 and a sedimentation pond 12, and a partition wall 13 separates the sewage pond 11 from the sedimentation pond 12; There are sewage circulation pipeline channels 111, raw water pipeline channels 112, and pH adjustment pipeline channels 113; a solid phase collection well 121 is provided at the bottom of the sedimentation tank, and a pipeline 122 that can discharge the contents of the well from the sedimentation tank is arranged in the solid phase collection well 121. The side wall of the sedimentation tank near the bottom is provided with a sewage discharge pi...

Embodiment 2

[0033] The coking wastewater treatment of a group in Jiangxi, the daily wastewater treatment reaches 1440t / d, the imported ammonia nitrogen value reaches 5021mg / L, and the foaming coefficient of the sewage reaches 2.52, which belongs to easy foaming sewage. If the circulation tank scheme is adopted, its volume needs to be at least 100 cubic meters, which not only occupies a large area and is expensive, but also makes defoaming in the tank very difficult. In response to this situation, an external circulating pool solution was adopted.

[0034] In this project, a sewage circulation pool of 120m is configured 3 The sewage treatment circulation pond comprises a sewage pond 11 and a sedimentation pond 12, and the separation wall 13 separates the sewage pond 11 from the sedimentation pond 12; The wall is provided with a sewage circulation pipeline channel 111, a raw water pipeline channel 112, and a pH adjustment pipeline channel 113; a solid phase collection well 121 is provided ...

Embodiment 3

[0038] A chemical plant in Hubei had an original sewage treatment system, and the ammonia nitrogen in the sewage discharged seriously exceeded the standard. The amount of ammonia nitrogen sewage discharged by the enterprise is only 20 tons per day, and the original sewage treatment system occupies a small area. However, the ammonia nitrogen value in sewage is as high as 3215mg / L, and at least level 2 is required to reduce it to below 200mg / L for biochemical treatment. The on-site inspection also found that if new equipment is added, its footprint must be less than 10m 2 . According to this situation, a two-stage vertical rotating foam separation denitrification device at room temperature and an external circulation pool scheme were adopted to achieve the expected goal that the ammonia nitrogen value at the outlet of the pretreatment system should not exceed 180mg / L for biochemical treatment. The actual floor area is controlled at 8m 2 Within this period, the problem of seri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com