Desulfurizer and its application

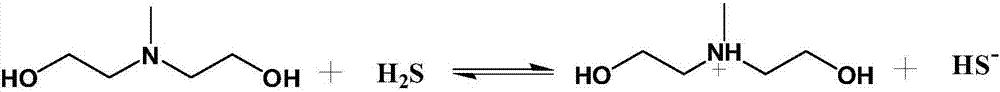

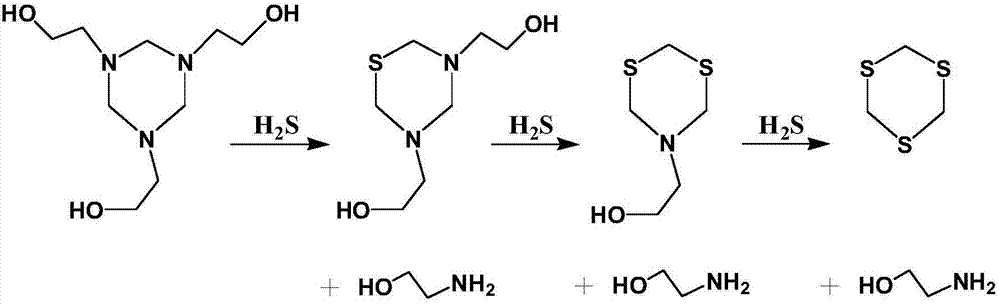

A desulfurizing agent and defoaming agent technology, applied in desulfurizing agent and its application field, can solve the problem of reducing desulfurization efficiency, and achieve the effects of high desulfurization efficiency, reducing reversible reaction and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

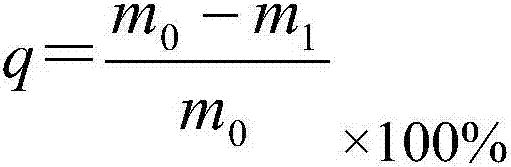

Method used

Image

Examples

Embodiment 1

[0036] A desulfurizer in this embodiment, its formula is: 20 parts of N-methyl triethanolamine, 20 parts of ferric ammonium EDTA, 20 parts of hydroxyethylhexahydro-s-triazine, 10 parts of methanol, 0.02 parts of emulsified silicone oil, succinic acid ester 2 parts of sodium sulfonate, 0.1 part of sodium nitrilotriacetate, 2 parts of acetic acid, 0.2 parts of sodium acetate, and 25.68 parts of water as a solvent, totaling 100 parts.

[0037] The specific preparation process of the above-mentioned desulfurizer is as follows: each raw material is weighed respectively according to the above-mentioned ratio, and methanol, N-methyl triethanolamine, ferric ammonium EDTA, hydroxyethylhexahydro-s-triazine and water are added into the reaction vessel, After stirring for 30 minutes, add the weighed acetic acid, sodium succinate sulfonate (Quick T), sodium acetate and polyether while stirring, and stir for 30 minutes to obtain the product.

Embodiment 2

[0039]A desulfurizer in this embodiment, its formula is: 20 parts of N-methyl triethanolamine, 20 parts of ferric ammonium EDTA, 20 parts of hydroxyethyl hexahydro-s-triazine, 8 parts of methanol, 0.02 parts of emulsified silicone oil, succinic acid ester 1.5 parts of sodium sulfonate, 0.15 parts of sodium nitrilotriacetate, 1.5 parts of acetic acid, 0.15 parts of sodium acetate, and 28.68 parts of water as a solvent, totaling 100 parts.

[0040] The preparation process of the above-mentioned desulfurizing agent is the same as that of Example 1, and no specific discussion is made here.

Embodiment 3

[0042] A desulfurizer in this embodiment, its formula is: 20 parts of N-methyl triethanolamine, 20 parts of ferric ammonium EDTA, 20 parts of hydroxyethyl hexahydro-s-triazine, 5 parts of methanol, 0.04 parts of emulsified silicone oil, succinic acid ester 1.5 parts of sodium sulfonate, 0.20 parts of sodium nitrilotriacetate, 1.5 parts of acetic acid, 0.15 parts of sodium acetate, and 31.61 parts of water as a solvent, totaling 100 parts.

[0043] The preparation process of the above-mentioned desulfurizing agent is the same as that of Example 1, and no specific discussion is made here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com