High-zinc-aluminum-manganese-iron-copper alloy for manufacturing of wire electrode for one-way wire winding

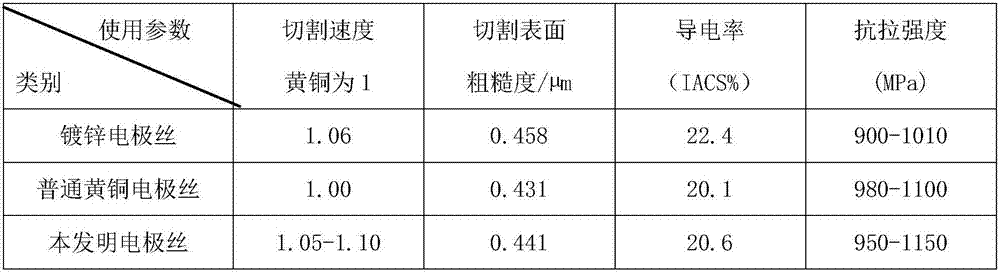

A technology of electrode wire and copper alloy, applied in the field of high zinc-aluminum-manganese-iron-copper alloy, can solve the problems of expensive production equipment, complicated preparation process, and numerous procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

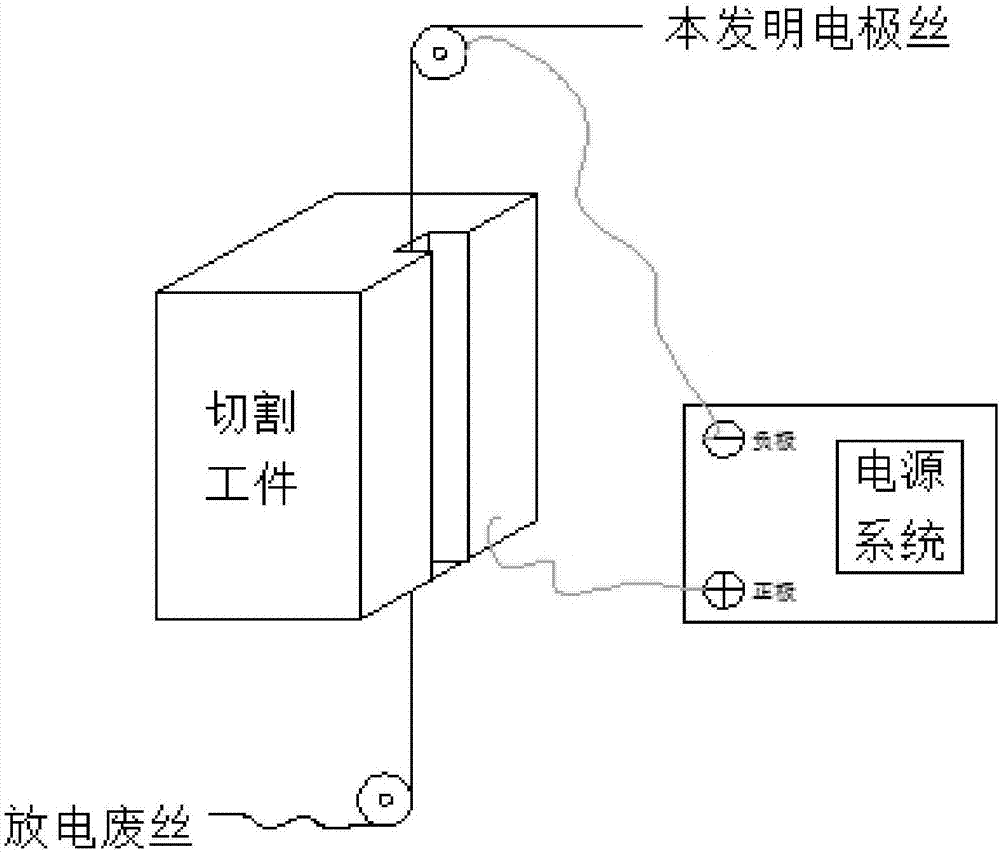

Image

Examples

Embodiment

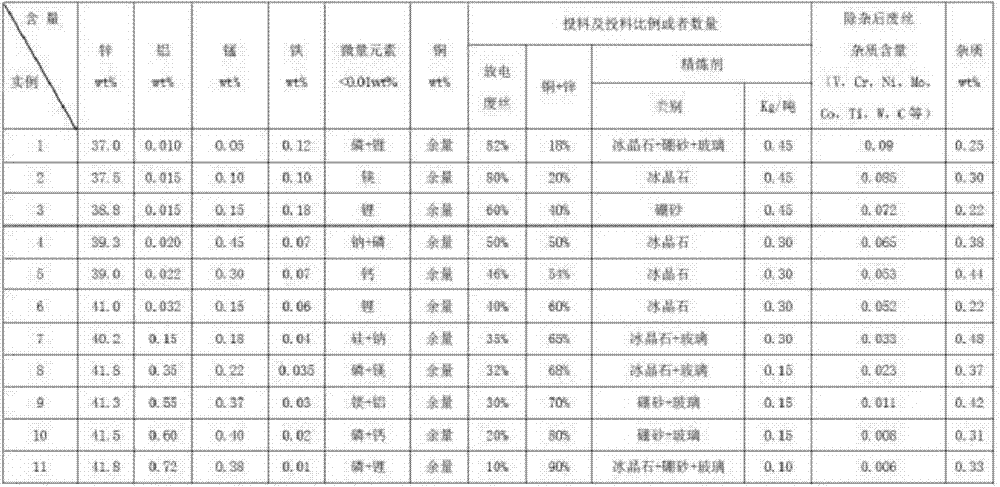

[0042] 1.1. For the discharge waste wire recycled by the customer, purchase aluminum, manganese, magnesium, silicon, sodium, lithium, potassium, calcium, and phosphorus at an appropriate market price, and start batching after passing the chemical analysis;

[0043] 1.2. According to the alloy composition shown in Table 1, mix ingredients with appropriate losses, and transport the prepared raw materials to the smelting site for smelting;

[0044] 1.3. Melting is an important process for manufacturing electrode wire materials. All the addition of alloying elements is completed in this process. Melting adopts continuous casting by upward drawing method, and the casting temperature is selected between 950-1080°C;

[0045] 1.4. The feeding sequence is: input of discharge waste wire → chemical analysis → copper and zinc compensation → input of one or more of cryolite, borax, glass → stirring → input of trace elements or their intermediate alloys → stirring → aluminum, manganese Or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com