Preparation method of stable type carbon paste electrode

A carbon paste electrode, stable technology, applied in the field of electrochemical analysis, can solve the problems of long response time, unstable physical and chemical properties of the test electrode surface, etc., to achieve the effect of reducing the adsorption rate, reducing the surface energy of the material, and improving the response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

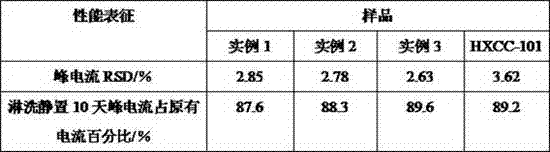

example 1

[0019] According to the mass ratio of 1:6, the paraffin oil and graphite particles were mixed and placed in a ball milling tank, and ball milled at 250r / min for 3 hours. After the ball milling was completed, the carbon paste was passed through a 200-mesh sieve. Fill it into a polytetrafluoroethylene material electrode tube with an inner diameter of 2mm, repeatedly compact the carbon paste with a copper rod, insert a copper wire at the other end of the electrode tube and fix it, extrude the carbon paste on the surface and polish it to obtain carbon Paste electrode, according to the mass ratio of 1:8, soak the carbon paste electrode in 8% sodium hydroxide solution, then use cyclic voltammetry to scan 45 circles in the 0.8V potential window, take out the carbon paste electrode and dry it in vacuum , to obtain an activated electrode; according to the mass ratio of 1:5, add fluorite ore powder to 1mol / L sodium silicate solution, stir and mix, and heat in an oil bath at 120 ° C. Afte...

example 2

[0021] According to the mass ratio of 1:6, the paraffin oil and graphite particles were stirred and mixed and placed in a ball milling tank, and ball milled at 275r / min for 4h. After the ball milling was completed, the carbon paste was passed through a 200 mesh sieve, and the carbon paste was Fill it into a polytetrafluoroethylene material electrode tube with an inner diameter of 3mm, repeatedly compact the carbon paste with a copper rod, insert a copper wire at the other end of the electrode tube and fix it, extrude the carbon paste on the surface and polish it to obtain carbon Paste electrode, according to the mass ratio of 1:8, soak the carbon paste electrode in 8% sodium hydroxide solution, and then use cyclic voltammetry to scan 47 circles in the 0.9V potential window, take out the carbon paste electrode and dry it in vacuum , to obtain an activated electrode; according to the mass ratio of 1:5, add fluorite ore powder to 1mol / L sodium silicate solution, stir and mix, and ...

example 3

[0023] According to the mass ratio of 1:6, the paraffin oil and graphite particles were mixed and placed in a ball milling tank, and ball milled at 300r / min for 5 hours. After the ball milling was completed, the carbon paste was passed through a 200-mesh sieve. Fill it into a polytetrafluoroethylene material electrode tube with an inner diameter of 3mm, repeatedly compact the carbon paste with a copper rod, insert a copper wire at the other end of the electrode tube and fix it, extrude the carbon paste on the surface and polish it to obtain carbon Paste electrode, according to the mass ratio of 1:8, soak the carbon paste electrode in 8% sodium hydroxide solution, then use cyclic voltammetry to scan 50 circles in the 1.0V potential window, take out the carbon paste electrode and dry it in vacuum , to obtain an activated electrode; according to the mass ratio of 1:5, add fluorite ore powder to 1mol / L sodium silicate solution, stir and mix, and heat in an oil bath at 130°C. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com