Polyoxyethylene sulfonate type dimeric surfactant and preparation method thereof

A technology of polyoxyethylene sulfonate and gemini surface, applied in the direction of chemical instruments and methods, dissolution, drilling compositions, etc., can solve the problems of surfactant resistance to salt and temperature resistance, etc., to improve crude oil The effects of recovery, mild reaction conditions, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

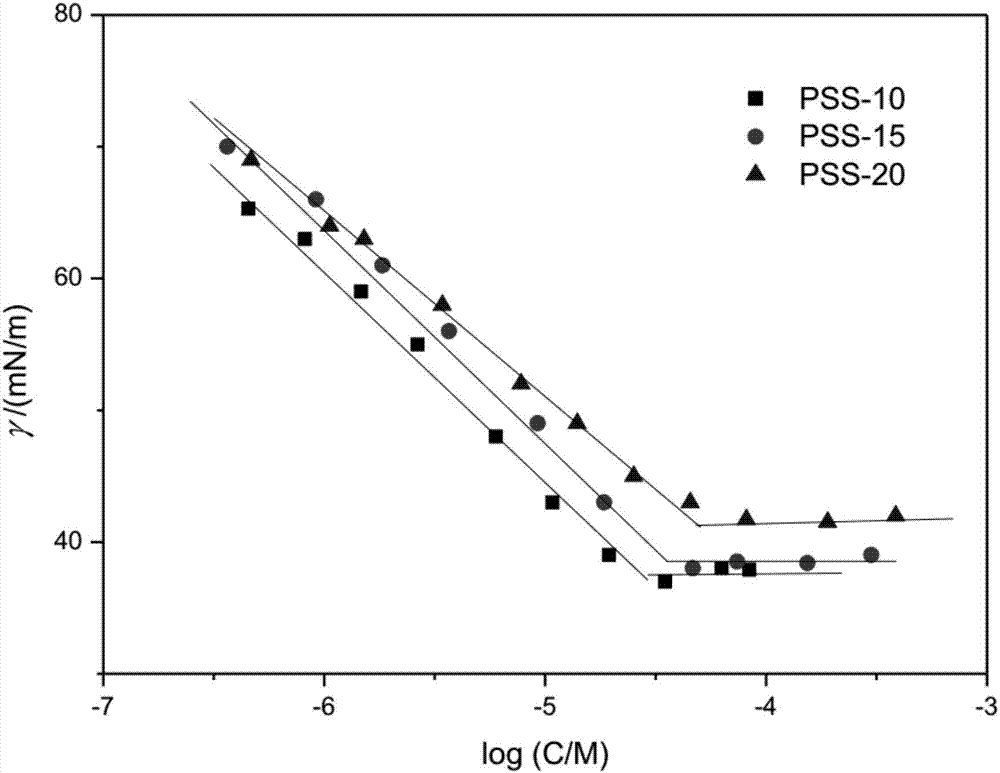

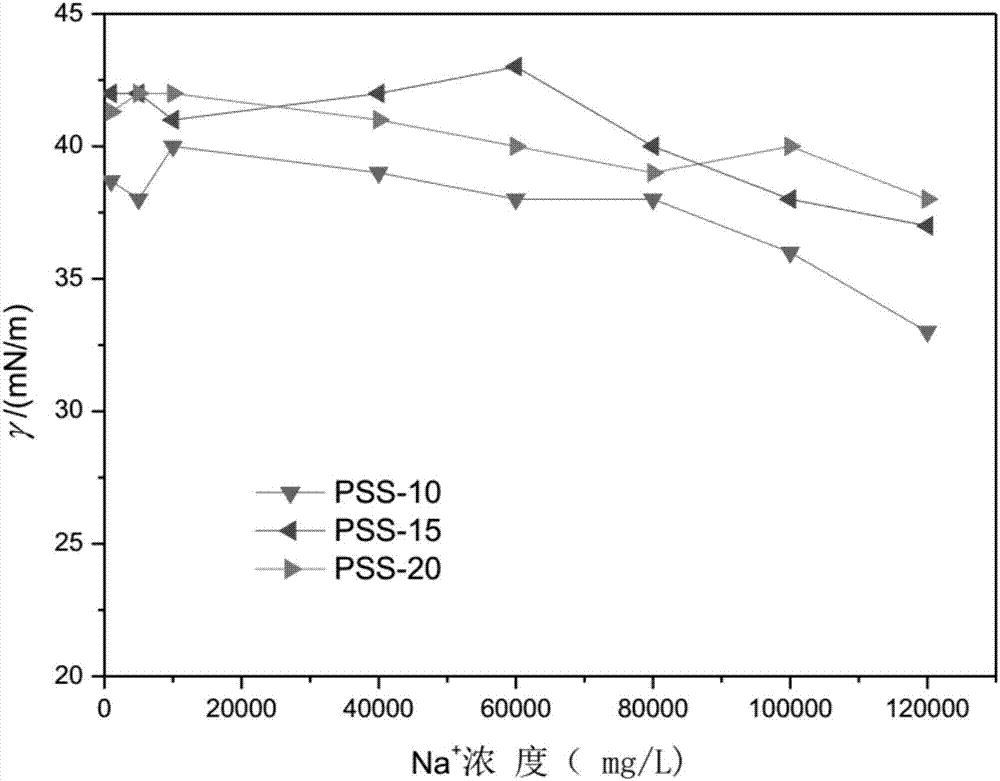

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a polyoxyethylene sulfonate type gemini surfactant, the structural formula of the polyoxyethylene sulfonate type gemini surfactant is as shown in formula (1):

[0032]

[0033] The present embodiment also provides the preparation method of above-mentioned polyoxyethylene sulfonate type gemini surfactant, it comprises the following steps:

[0034] (1) Preparation of di-nonylphenol: weigh p-nonylphenol and formaldehyde according to the molar ratio of 2:1, add p-nonylphenol to the flask, then add 0.495g of dihydrate oxalic acid, 0.325g to Ionized water and 0.185g of sodium dodecylbenzenesulfonate were added in batches of solid formaldehyde while the temperature was rising to 90°C, stirred and mixed evenly, then the temperature was raised to 120°C, connected to a water separator, and reacted for 4 hours. After the reaction, the product was extracted with dichloromethane, then dried and rotary evaporated, followed by column chromatography to purif...

Embodiment 2

[0039] This embodiment provides a polyoxyethylene sulfonate type gemini surfactant, the structural formula of the polyoxyethylene sulfonate type gemini surfactant is as shown in formula (2):

[0040]

[0041]The present embodiment also provides the preparation method of above-mentioned polyoxyethylene sulfonate type gemini surfactant, it comprises the following steps:

[0042] (1) Preparation of diheptylphenol: Weigh p-heptylphenol and formaldehyde according to the ratio of molar ratio of 2.5:1, add p-heptylphenol to the flask and then add 0.512g of dihydrate oxalic acid, 0.345g to Ionized water and 0.185g of sodium dodecylbenzenesulfonate were added in batches of solid formaldehyde while the temperature was rising to 90°C, stirred and mixed evenly, then the temperature was raised to 120°C, connected to a water separator, and reacted for 6 hours. After the reaction was completed, the product was extracted with dichloromethane, dried and rotary evaporated with anhydrous magn...

Embodiment 3

[0047] This embodiment provides a polyoxyethylene sulfonate type gemini surfactant, the structural formula of the polyoxyethylene sulfonate type gemini surfactant is as shown in formula (3):

[0048]

[0049] The present embodiment also provides the preparation method of above-mentioned polyoxyethylene sulfonate type gemini surfactant, it comprises the following steps:

[0050] (1) Preparation of didodecylphenol: weigh p-dodecylphenol and formaldehyde according to the molar ratio of 2.2:1, add p-dodecylphenol to the flask and then add 0.48g of didodecylphenol Hydrate oxalic acid, 0.33g deionized water and 0.17g sodium dodecylbenzenesulfonate, add solid formaldehyde in batches during the process of heating up to 90°C, stir and mix evenly, then raise the temperature to 120°C, connect the water separator, and react for 5h . After the reaction was completed, the product was extracted with dichloromethane, dried and rotary evaporated with anhydrous magnesium sulfate, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com