Rapid biofilm formation method for low C/N ratio waste water treatment using calcium ion-regulated biofilm method

A biofilm method and calcium ion technology, which is applied in the field of calcium ion-regulated biofilm method to treat low C/N ratio wastewater and fast film hanging, can solve the problems of inconvenient operation, need to monitor, and not easy to control, achieve simple operation, strengthen the overall Strong and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

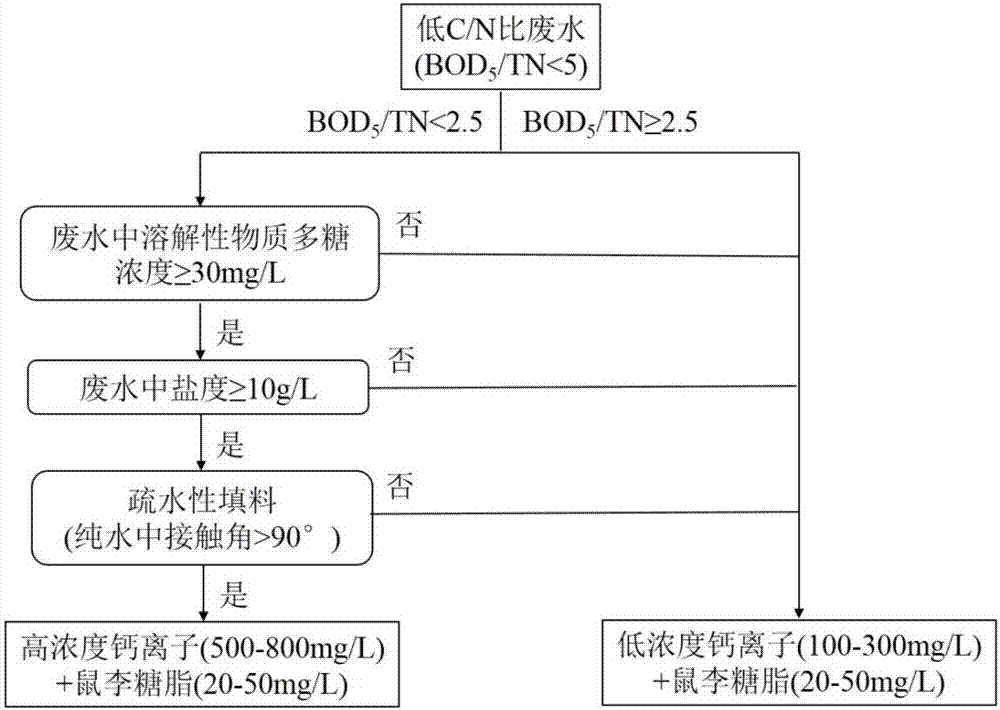

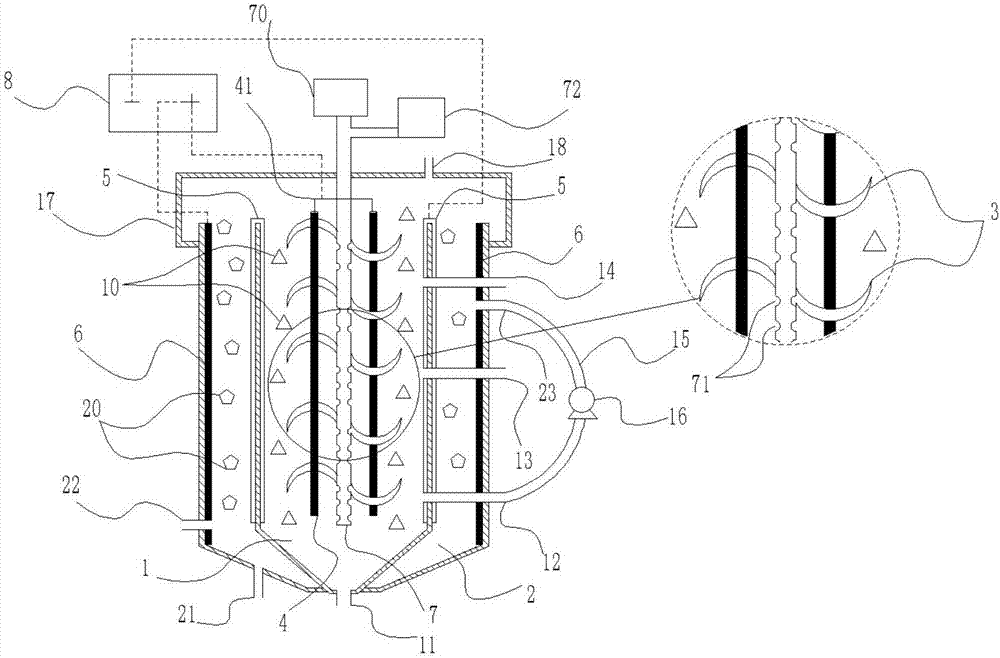

[0032] This example is about the rapid film-forming method of organic filler in the treatment of high-salinity wastewater with a BOD5 / TN ratio of 1-2.5 by continuous flow moving bed biofilm reactor (MBBR).

[0033] Wastewater quality: BOD5 concentration is 200mg / L, TN concentration is 100mg / L, salinity is 12g / L, soluble polysaccharide concentration in wastewater is 60mg / L. The suspended filler is made of polystyrene, and its pure water contact angle is 99.8±2.23°, showing the characteristics of hydrophobicity. Its shape is a hollow cylinder, with a support structure inside and gears outside. The outer diameter and height of the filler are 25mm and 10mm respectively, and the density is about 0.95g / cm3 , its effective specific surface area is about 460m 2 / m 3 .

[0034] According to the water quality and filler material conditions, the treatment plan of adding high-concentration calcium ions (800mg / L) supplemented with a certain concentration of rhamnolipid (50mg / L) is select...

Embodiment 2

[0043] This example is about the rapid film-forming method of organic filler in the treatment of low-salinity wastewater with a BOD5 / TN ratio of 2.5-5 by the continuous flow biofilm reactor method.

[0044] Wastewater quality: BOD5 concentration is 500mg / L, TN concentration is 150mg / L, salinity is 500mg / L, soluble polysaccharide concentration in wastewater is 10mg / L. The suspension filler is made of polypropylene, and its pure water contact angle is 68.5±1.52°, showing the characteristics of hydrophilicity. Its shape is spherical, which is divided into inner and outer double-layer spheres, the outer is a hollow fishnet-shaped sphere, and the inner is a rotating sphere.

[0045] According to the water quality and filler material conditions, the treatment plan of adding low-concentration calcium ions (100mg / L) supplemented with a certain concentration of rhamnolipid (20mg / L) is selected, and at the same time, no calcium ions and high-concentration calcium ions are added. (800mg / ...

Embodiment 3

[0055] This example is about the rapid film-forming method of organic filler in the biological aerated filter (BAF) treatment of low-salinity wastewater with a BOD5 / TN ratio of 2.5-5.

[0056] Wastewater quality: BOD5 concentration is 500mg / L, TN concentration is 150mg / L, salinity is 400mg / L, soluble polysaccharide concentration in wastewater is 20mg / L. The carrier filler adopts clay ceramic particles.

[0057] According to relevant conditions, select to add low concentration calcium ion (100mg / L) and be supplemented with the processing scheme of rhamnolipid (30mg / L) of certain concentration, simultaneously with not adding calcium ion and adding high concentration calcium ion (800mg / L) The treatment scheme of L) is used as contrast.

[0058] Its fast film-forming method is:

[0059] (1) Put the sludge taken from the aerobic tank of the municipal sewage treatment plant with a concentration of 3g / L into the BAF reactor, discharge all the inoculated sludge after aeration for 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com