Cassava distiller's grain organic fertilizer and production method thereof

A technology of cassava distiller's grains and production methods, applied in the direction of organic fertilizers, inorganic fertilizers, nitrogen fertilizers, etc., can solve the problems of restricting the reuse of cassava distiller's grains, low utilization rate of cassava distiller's grains, difficulties in dehydration and storage, etc., and achieve good application prospects and increase production effects Obvious and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

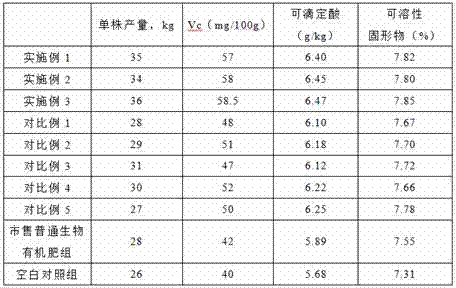

Examples

Embodiment 1

[0034] A method for producing cassava distiller's grains organic fertilizer, comprising the steps of:

[0035] Step (1), add cellulase and EM bacterial liquid to the cassava distiller's grains, stir until the mixture is uniform, and carry out anaerobic fermentation for 3 days under sealed conditions. During the fermentation process, stir once every 12 hours until the mixture is uniform;

[0036] The added quality of cellulase is 0.01% of the quality of cassava distiller's grains, and the added quality of EM bacterial liquid is 0.1% of the quality of cassava distiller's grains, wherein; the amount of bacteria in each milliliter of EM bacterial liquid is 200-400 million;

[0037] Step (2), centrifuging the fermentation product obtained in step (1) to obtain supernatant and sedimentation residue; freeze-drying the supernatant to obtain material A; adjusting the pH of the sedimentation residue to 6-7, and then, with the sugar factory After the filter mud, fulvic acid, zeolite powd...

Embodiment 2

[0043] A method for producing cassava distiller's grains organic fertilizer, comprising the steps of:

[0044] Step (1), add cellulase and EM bacterial liquid to the cassava distiller's grains, stir until the mixture is uniform, and carry out anaerobic fermentation for 5 days under sealed conditions. During the fermentation process, stir once every 13 hours until the mixture is uniform;

[0045] The added quality of cellulase is 0.05% of the quality of cassava distiller's grains, and the added quality of EM bacterial liquid is 0.5% of the quality of cassava distiller's grains, wherein; the amount of bacteria per milliliter of EM bacterial liquid is 8-1 billion;

[0046] Step (2), centrifuging the fermentation product obtained in step (1) to obtain supernatant and sedimentation residue; freeze-drying the supernatant to obtain material A; adjusting the pH of the sedimentation residue to 6-7, and then, with the sugar factory After the filter mud, fulvic acid, zeolite powder and t...

Embodiment 3

[0052] A method for producing cassava distiller's grains organic fertilizer, comprising the steps of:

[0053] Step (1), add cellulase and EM bacterial liquid to the cassava distiller's grains, stir until evenly mixed, and then carry out anaerobic fermentation for 4 days under sealed conditions. During the fermentation process, stir once every 12.5 hours until evenly mixed ;

[0054] The added quality of cellulase is 0.03% of the quality of cassava distiller's grains, and the added quality of EM bacterial liquid is 0.3% of the quality of cassava distiller's grains, wherein; the amount of bacteria per milliliter of EM bacterial liquid is 500-600 million;

[0055] Step (2), centrifuging the fermentation product obtained in step (1) to obtain supernatant and sedimentation residue; freeze-drying the supernatant to obtain material A; adjusting the pH of the sedimentation residue to 6-7, and then, with the sugar factory After the filter mud, fulvic acid, zeolite powder and tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com