A kind of method that reclaims phenylacetic acid from penicillin potassium lysate

A technology of penicillin potassium and lysate is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate salts, etc., and can solve the problems of increasing environmental protection processing pressure and difficult viscous liquids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

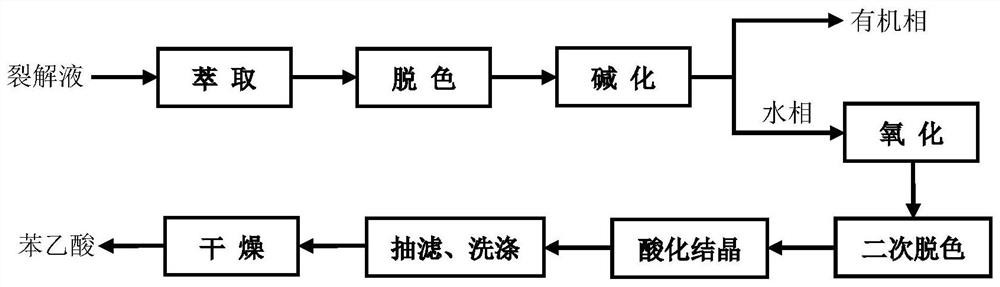

Method used

Image

Examples

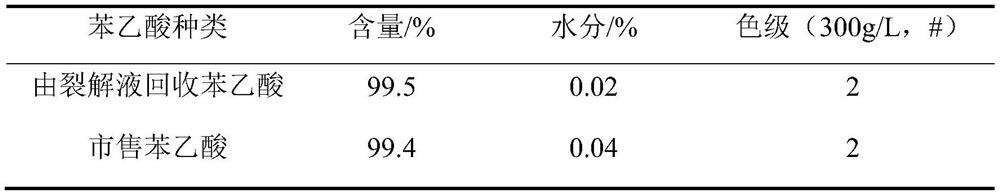

Embodiment 1

[0036] Embodiment 1 The method for reclaiming phenylacetic acid from penicillin potassium lysate according to the present invention

[0037] (1) Extraction of penicillin potassium lysate

[0038] Take 1L of the penicillin potassium lysate, measure its phenylacetic acid concentration to 27.69g / L by high performance liquid phase, lower the temperature to 5°C, and under stirring, add 500mL of the organic solvent toluene for extraction to the penicillin potassium lysate, add 30 % hydrochloric acid, adjust the pH of the feed liquid to 0.92, stir for 5 min, pour the mixed feed liquid into a separating funnel and let stand for phase separation to obtain 510 mL of an organic phase, which is for later use;

[0039] (2) Decolorization

[0040] 5.1g of activated carbon was added to the organic phase obtained in step (1), stirred for 30min, and filtered with suction to obtain the decolorized organic phase, which was used for subsequent use;

[0041] (3) Alkalization

[0042] To the dec...

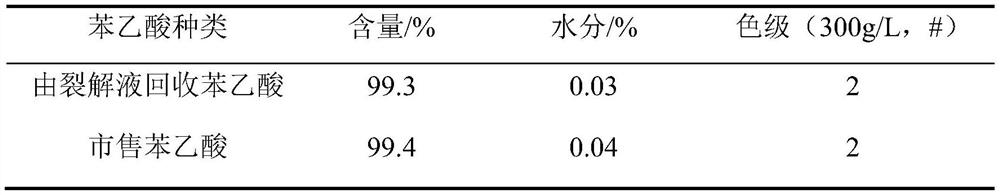

Embodiment 2

[0053] Embodiment 2 The method for reclaiming phenylacetic acid from penicillin potassium lysate according to the present invention

[0054] (1) Extraction of penicillin potassium lysate

[0055] Take 1L of the penicillin potassium lysate, measure its phenylacetic acid concentration to be 27.69g / L by high performance liquid phase, lower the temperature to 15°C, and under stirring, add 500mL of the organic solvent dichloromethane for extraction to the penicillin potassium lysate, Add 30% hydrochloric acid, adjust the pH of the feed liquid to 0.8, stir for 10 min, pour the mixed feed liquid into a separatory funnel and let stand for phase separation to obtain 510 mL of an organic phase, which is for later use;

[0056] (2) Decolorization

[0057] To the organic phase obtained in step (1), add 5.1 g of activated carbon, stir for 60 min, and filter with suction to obtain the decolorized organic phase, which is for subsequent use;

[0058] (3) Alkalization

[0059] To the decolo...

Embodiment 3

[0070] Embodiment 3 The method for reclaiming phenylacetic acid from penicillin potassium lysate according to the present invention

[0071] (1) Extraction of penicillin potassium lysate

[0072] Take 1L of the penicillin potassium lysate, determine its phenylacetic acid concentration to be 27.69g / L by high performance liquid phase, lower the temperature to 15°C, and under stirring, add 500mL of the organic solvent MIBK for extraction to the penicillin potassium lysate, add 20 % hydrochloric acid, adjust the pH of the feed liquid to 1.5, stir for 10 min, pour the mixed feed liquid into a separatory funnel and let stand for phase separation to obtain 515 mL of an organic phase, which is for later use;

[0073] (2) Decolorization

[0074] 5.15g of activated carbon was added to the organic phase obtained in step (1), stirred for 30min, and filtered with suction to obtain the decolorized organic phase for subsequent use;

[0075] (3) Alkalization

[0076] To the decolorized org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com