Continuous ammoniation method of aniline organic intermediates

An intermediate, aniline technology, applied in the field of continuous amination of aniline organic intermediates, can solve the problems of increased equipment investment and energy consumption, reduced safety and cleanliness, increased product post-processing procedures, etc., and achieves saving synthesis costs, The effect of optimizing the process design and meeting the requirements of the process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

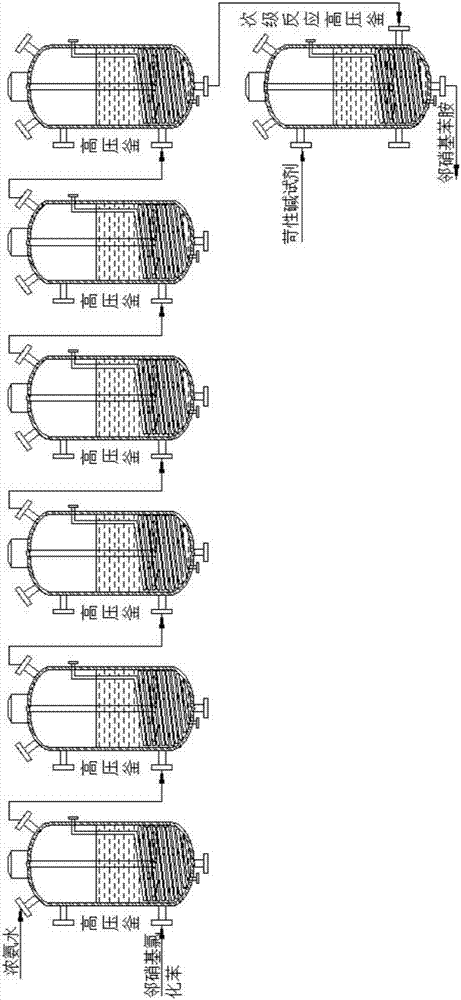

[0025] see figure 1 Shown, the technical scheme that the present invention adopts is: a kind of continuous ammoniation method of aniline organic intermediate, and the concrete of described preparation method comprises the following steps:

[0026] (1). Primary reaction: transfer a certain amount of o-nitrochlorobenzene and concentrated ammonia water of a certain concentration into the autoclave connected in six stages, set the temperature, pressure and stirring rate inside the autoclave, and react for a period of time. Obtain o-nitroaniline solution;

[0027] (2). Secondary reaction: transfer the obtained o-nitroaniline solution into the secondary reaction autoclave, set the reaction pressure, reaction temperature and stirring rate in the secondary reaction autoclave, then add caustic alkali dropwise Reagent, adjust the pH value, and after reacting for a while, high-purity o-nitroaniline solution and by-products are obtained.

[0028] Working principle: When in use, react ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com