Synthesis method of creatinol phosphate

A technique of myo-inositol phosphate and a synthesis method, which is applied in the field of organic synthesis, can solve problems such as increased equipment corrosion, acetic acid has a strong volatile odor, and difficulty in crystallization and separation, and achieves easy purification and recovery, low drying temperature, and increased yield and the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In view of this, in a specific embodiment of the present invention, a kind of synthetic method of inositol phosphate is provided, comprising steps as follows:

[0051] (1) Add lime nitrogen to the mixed solution of ethanol and water under a carbon dioxide atmosphere, continuously feed carbon dioxide to make the pH of the reaction solution to 7.5 to 8.5, and filter to obtain an ethanol solution of cyanamide;

[0052] (2) adding concentrated phosphoric acid to the ethanol and 2-(methylamino) ethanol solution to adjust the pH to 5-7, and adding dropwise the ethanol solution of cyanamide in the step (1) therein under the temperature condition of 50-70°C, The white myo-inositol phosphate was precipitated from the reaction, and myo-inositol phosphate was purified.

[0053] Wherein, the mass ratio of ethanol, lime nitrogen and water in step (1) (10-20): (3-5): (1-2), preferably 15:4:1; the pH of the reaction solution is 8; By adopting the above ratio, sufficient moisture can ...

Embodiment 1

[0070] (1) Add 300g of 95% ethanol and 25g of distilled water to a 1L reaction kettle with a mechanical stirrer, and then pass in carbon dioxide, add 80g of lime nitrogen to the reaction solution under stirring, and continue to pass in after the addition of lime nitrogen is completed Carbon dioxide to pH=8, stop the reaction, filter to obtain 256g of ethanol solution of cyanamide. During the whole reaction process, the reaction temperature is controlled below 50°C through a circulating water bath;

[0071] (2) In the reactor with mechanical stirrer, add 128g 95% ethanol and 32g 2-(methylamino) ethanol, add 52g 85% phosphoric acid to adjust pH to be 6, step (1) solution is dripped under the condition of 60 ℃ Added to the reaction system, directly reacted to obtain white inositol phosphate precipitate. Filter, wash with absolute ethanol, and vacuum-dry myo-inositol phosphate 68g (based on 2-(methylamino)ethanol, the yield is 74%).

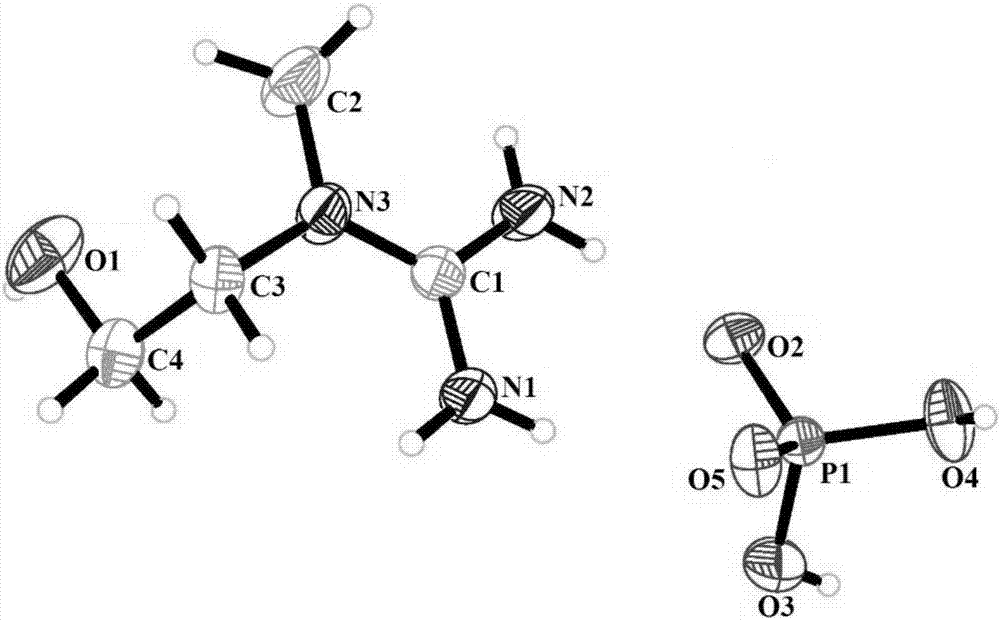

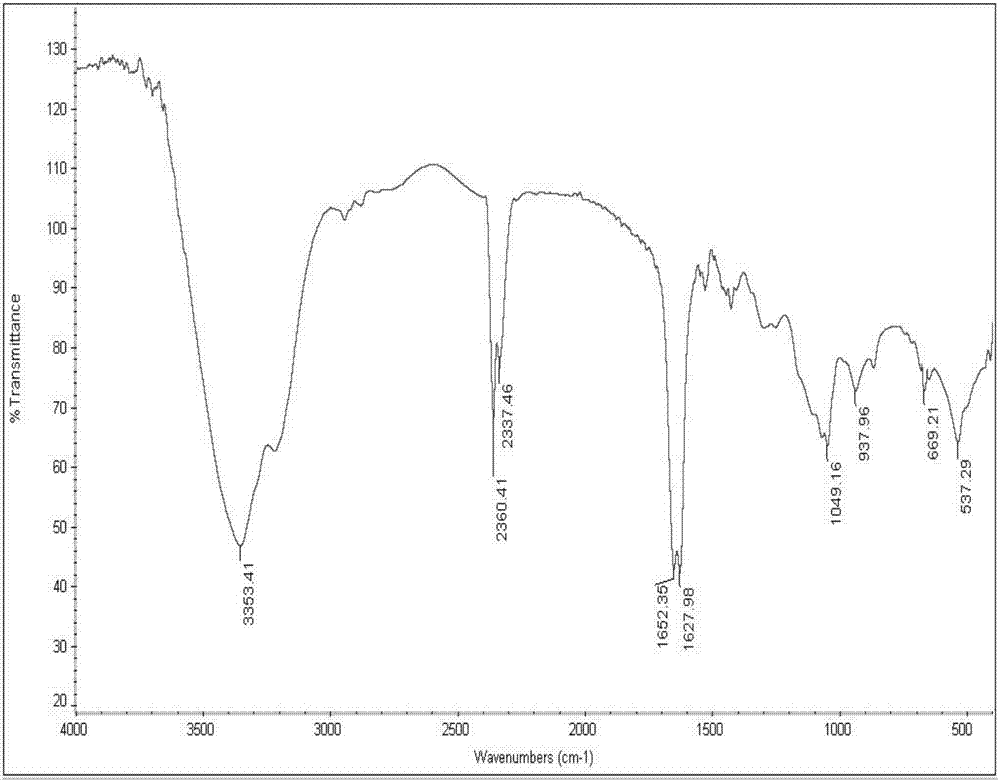

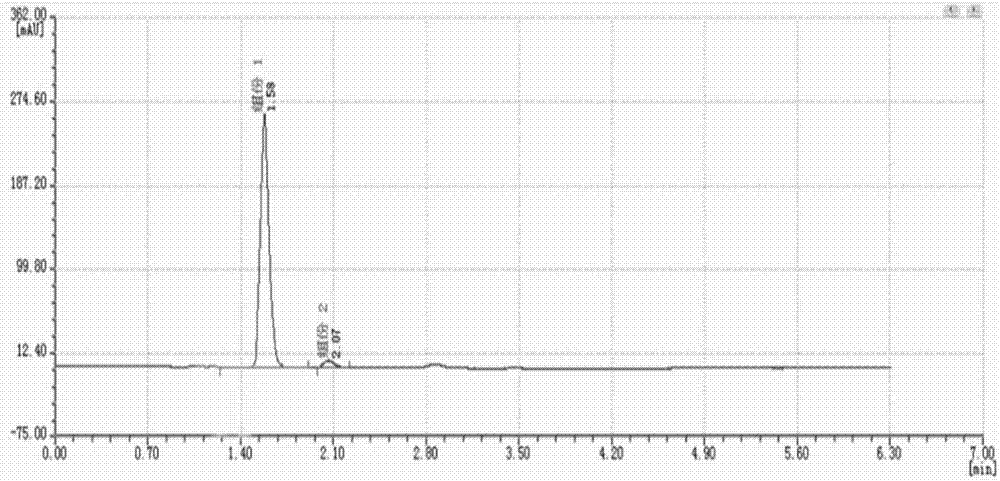

[0072] Depend on figure 1 with figure 2 I...

Embodiment 2

[0074] (1) Add 320g of 95% ethanol, 20g of distilled water, and then carbon dioxide into a 1L reaction kettle with a mechanical stirrer, and add 96g of lime nitrogen into the reaction solution under stirring, and continue to feed the lime nitrogen after adding carbon dioxide to pH=8, stop the reaction, and filter to obtain 258 g of ethanol solution of cyanamide. During the whole reaction process, the reaction temperature is controlled below 50°C through a circulating water bath;

[0075] (2) In the reactor with mechanical stirrer, add 128g 95% ethanol and 32g 2-(methylamino) ethanol, add 52g 85% phosphoric acid to adjust pH to be 6, step (1) solution is dripped under the condition of 60 ℃ Added to the reaction system, directly reacted to obtain white inositol phosphate precipitate. Filter, wash with absolute ethanol, and vacuum-dry inositol phosphate 69g (calculated as 2-(methylamino)ethanol, the yield is 75%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com