Polyurethane plastic foaming agent with electrostatic shielding function

An electrostatic shielding and polyurethane technology, applied in the field of preparation of polyurethane plastic foaming agent, can solve the problems of difficult control of cell size of foamed products, difficult control of reaction process, narrow application range, etc., and achieves good comprehensive use performance and easy operation. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

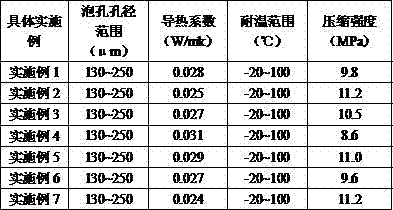

Examples

Embodiment 1

[0034] A kind of foaming agent for polyurethane plastics with electrostatic shielding function, the specific process of preparing foaming agent is as follows:

[0035]Heat 10kg of metallic nickel until it melts, add 0.2kg of silicon carbide, then pass a mixed gas of nitrogen and argon into the molten metallic nickel liquid, and keep stirring until the molten liquid is cooled to obtain foam metal; the obtained foam The metal is placed in absolute ethanol, washed by ultrasonic waves to remove organic matter, then washed three times with distilled water, and dried at room temperature. Then place it in a muffle furnace, heat it to 600°C in an air atmosphere, keep it warm for 17 minutes, pre-oxidize it and grind it to the nanometer level; then dissolve 20kg of micronized sodium bicarbonate in deionized water with a concentration of 70g / L solution, put the nano-scale metal foam in the solution, heat it to 35°C under high-speed stirring at 600r / min, to evaporate the water, and the s...

Embodiment 2

[0040] A kind of foaming agent for polyurethane plastics with electrostatic shielding function, the specific process of preparing foaming agent is as follows:

[0041] Heat 10kg of metal iron until it melts, add 0.3kg of alumina, then pass a mixed gas of nitrogen and argon into the molten metal iron liquid, and keep stirring until the molten liquid is cooled to obtain foam metal; The metal is placed in absolute ethanol, washed by ultrasonic waves to remove organic matter, then washed three times with distilled water, and dried at room temperature. Then place it in a muffle furnace, heat it to 600°C in an air atmosphere, keep it warm for 20 minutes, pre-oxidize it and grind it to the nanometer level; then dissolve 25kg of micronized sodium bicarbonate in deionized water with a concentration of 70g / L solution, put the nano-scale metal foam in the solution, heat it at a low temperature to 40°C under high-speed stirring at 700r / min to evaporate the water, and the sodium bicarbona...

Embodiment 3

[0046] A kind of foaming agent for polyurethane plastics with electrostatic shielding function, the specific process of preparing foaming agent is as follows:

[0047] Heat 10kg of metallic nickel to melt, add 0.2kg of magnesia, then pass a mixed gas of nitrogen and argon into the molten metallic nickel liquid, and keep stirring until the molten liquid is cooled to obtain foam metal; the obtained foam The metal is placed in absolute ethanol, washed by ultrasonic waves to remove organic matter, then washed three times with distilled water, and dried at room temperature. Then put it in a muffle furnace, heat it to 580°C in an air atmosphere, keep it warm for 12 minutes, pre-oxidize it and grind it to the nanometer level; then dissolve 30kg of micronized sodium bicarbonate in deionized water, and the concentration is 72g / L solution, put the nano-scale metal foam in the solution, heat it to 38°C under high-speed stirring at 680r / min to evaporate the water, and the sodium bicarbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com