A kind of preparation method of high-efficiency diesel oil pour point depressant

A diesel oil pour point depressant, high-efficiency technology, applied in the field of oil additives, can solve the problems of small freezing point and cold filter point range, single polymer type, little effect of diesel oil, etc., to reduce the freezing point of diesel oil, and the synthesis method is simple , excellent pour point depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

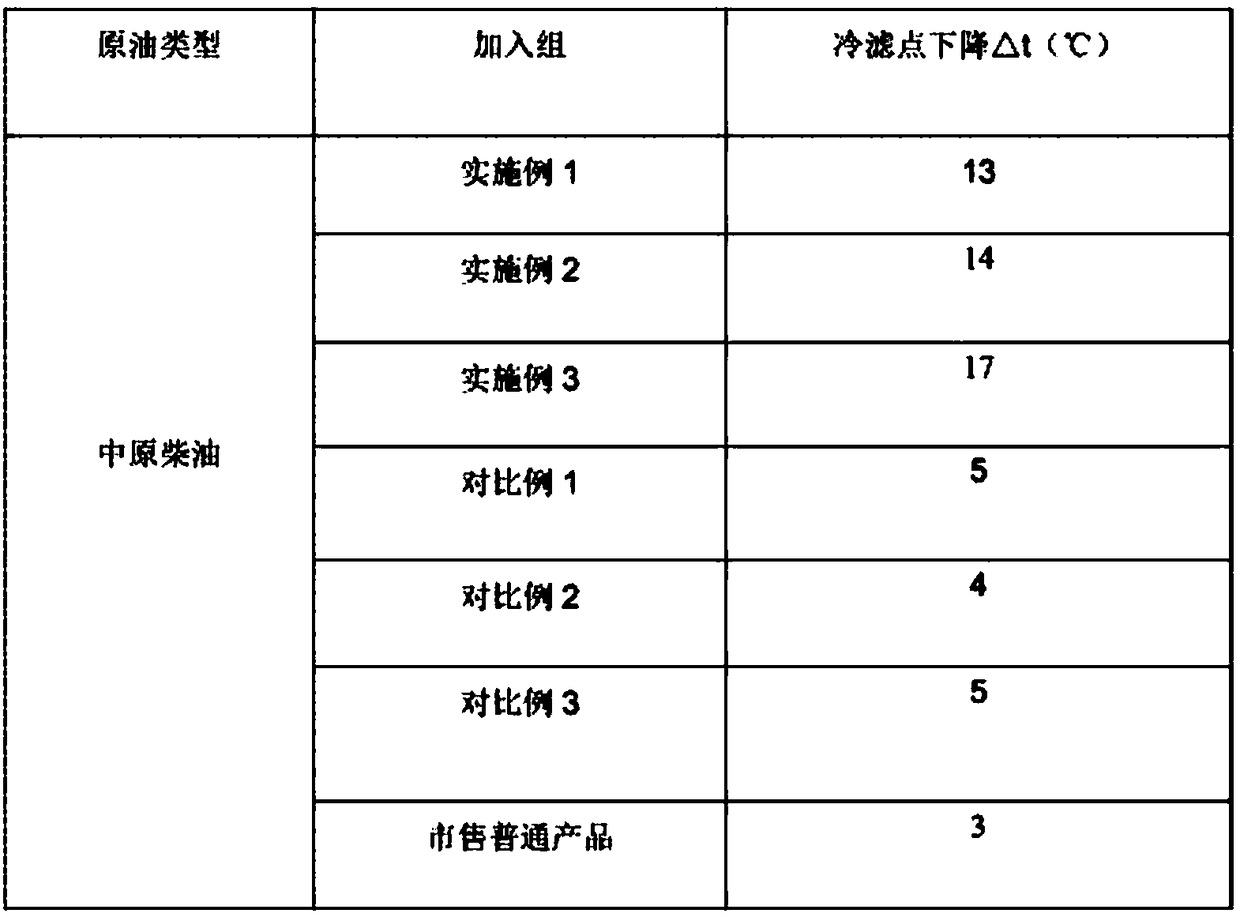

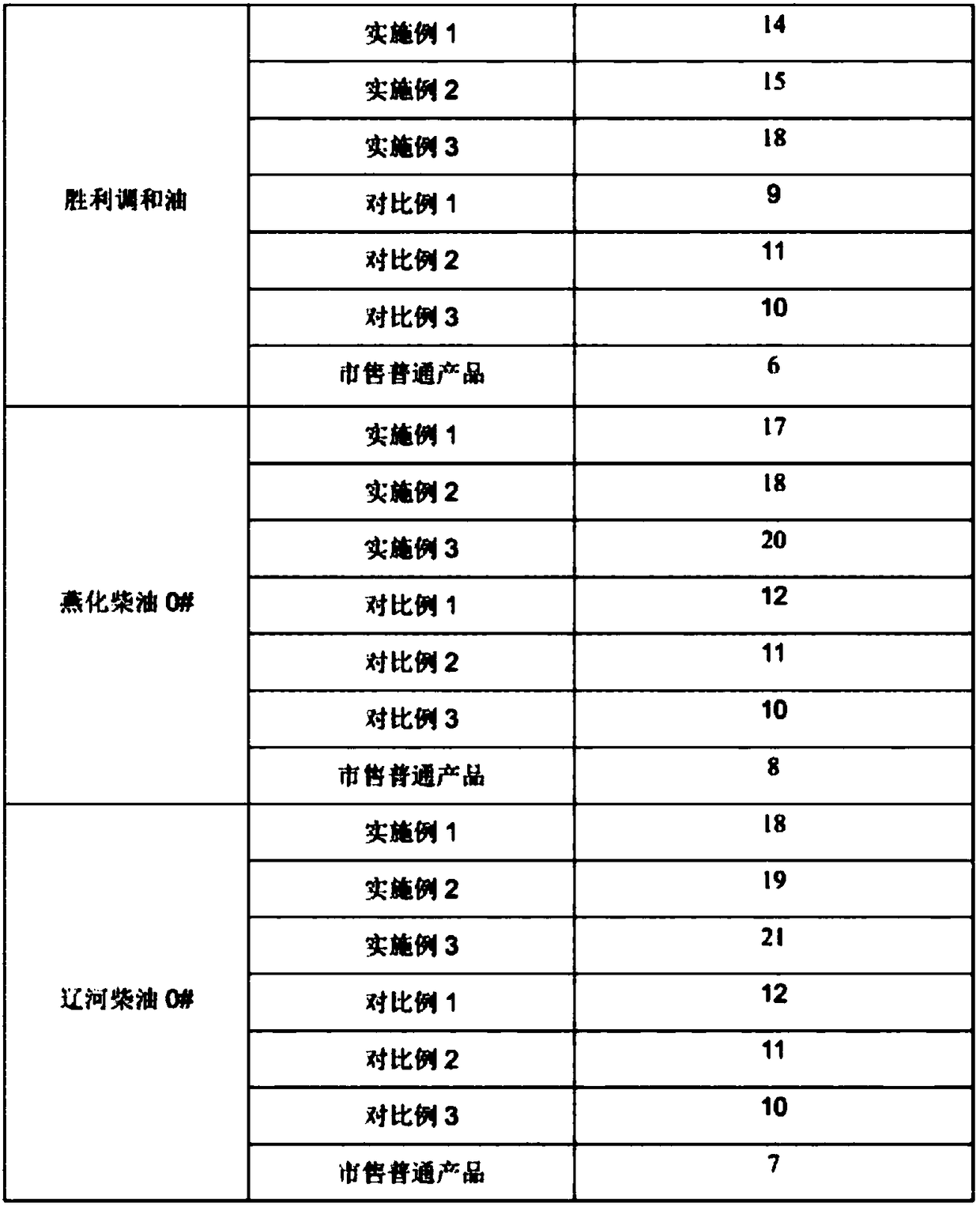

Examples

preparation example Construction

[0023] The present invention proposes a kind of preparation method of high-efficiency diesel oil pour point depressant, comprises following preparation steps:

[0024] Step 1. Weigh 1-2 parts of wisteria flowers, crush them by airflow, pass through 80-100 mesh sieves, add them into 15-20 parts of ethanol, ultrasonically extract for 1-2 hours, filter with nanofiltration membrane, and take the filtrate to obtain plant extracts;

[0025] Step 2: Add 50 to 60 parts of ethyl acetate to the plant extract obtained in the above step 1, stir and heat up to 60 to 70°C; then add 5 to 8 parts of tetrahydrofurfuryl methacrylate, 6 ~8 parts of trimethylolpropane triacrylate, 3~5 parts of ethoxylated trimethylolpropane triacrylate and 15~20 parts of acrylic acid; then under the stirring condition of 100~200r / min, drop Add 0.1-0.5 parts of methyl ethyl ketone peroxide, stir and react at a speed of 100-200r / min for 3-5 hours, then add 2-3 parts of aminotrimethylene phosphonic acid, Stir at a...

Embodiment 1

[0028] On the basis of specific implementation, the preparation method of the high-efficiency diesel pour point depressant of the present embodiment comprises the following preparation steps:

[0029] Step 1. Weigh 1 part of wisteria flower, crush it by airflow, pass it through an 80-mesh sieve, add it to 15 parts of ethanol, extract it ultrasonically for 1 hour, filter it with a nanofiltration membrane, and take the filtrate to obtain a plant extract;

[0030] Step 2: Add 50 parts of ethyl acetate to the plant extract obtained in the above step 1, stir and heat up to 60°C; then add 5 parts of tetrahydrofurfuryl methacrylate and 6 parts of trimethylol Propane triacrylate, 3 parts of ethoxylated trimethylolpropane triacrylate and 15 parts of acrylic acid; then under stirring condition of 100r / min, 0.1 part of methyl ethyl ketone peroxide was added dropwise at a speed of 100r / min After stirring and reacting for 3 hours, add 2 parts of aminotrimethylene phosphonic acid, and stir ...

Embodiment 2

[0033] On the basis of specific implementation, the preparation method of the high-efficiency diesel pour point depressant of the present embodiment comprises the following preparation steps:

[0034] Step 1. Weigh 2 parts of wisteria flowers, crush them by airflow, pass through a 100-mesh sieve, add them to 20 parts of ethanol, extract them ultrasonically for 2 hours, filter them with a nanofiltration membrane, and take the filtrate to obtain a plant extract;

[0035] Step 2: Add 60 parts of ethyl acetate to the plant extract obtained in the above step 1, stir and heat up to 70°C; then add 8 parts of tetrahydrofurfuryl methacrylate and 8 parts of trimethylol Propane triacrylate, 5 parts of ethoxylated trimethylolpropane triacrylate and 20 parts of acrylic acid; then under 200r / min stirring condition, dropwise add 0.5 part of methyl ethyl ketone peroxide, with 200r / min rotating speed After stirring and reacting for 5 hours, add 3 parts of aminotrimethylene phosphonic acid, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com