Sensor chip and manufacturing method thereof

A sensor chip, chip technology, applied in the direction of scattering characteristics measurement, etc., to achieve the effect of abundant quantity, good response signal and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

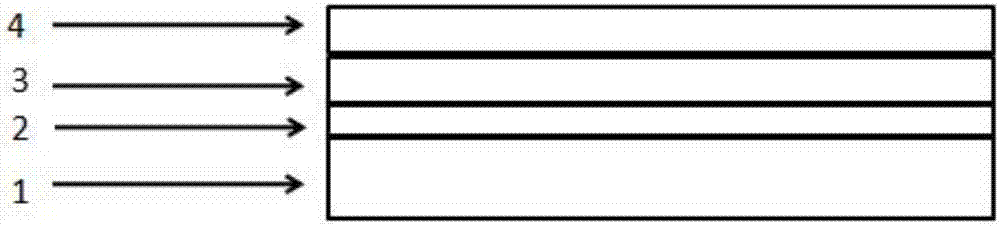

[0042] Such as figure 1 As shown, a sensor chip is composed of a glass substrate 1, a metal film 2, a self-assembled film 3 and a composite film 4 of metal oxide and polymer from bottom to top in sequence. The specific preparation steps of the sensor chip are as follows:

[0043] Step 1. Coating a metal film 2 with a thickness of 49 nm on the glass substrate 1 by vacuum evaporation;

[0044] Step 2. Place the glass substrate 1 after the vapor-deposited metal film 2 in allyl mercaptan with a concentration of 1mmol / L, and after standing still for 24h, take out the glass substrate 1 from the allyl mercaptan, and use Rinse with absolute ethanol and dry with high-purity nitrogen to form a self-assembled film 3 on the metal film 2;

[0045] Step 3. Disperse the titanium dioxide powder into distilled water and ultrasonically mix to obtain a concentration of 1×10 -6 mol / L suspension solution;

[0046] Step 4. Mix 0.0355g of acrylamide, 0.0062g of N,N'-methylenebisacrylamide and 950...

Embodiment 2

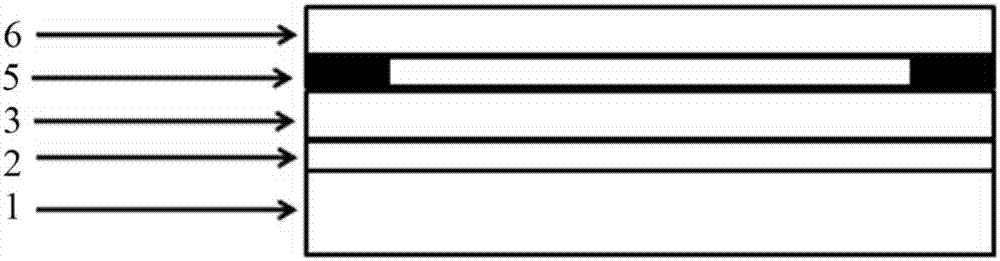

[0051] A sensor chip consists of a glass substrate 1, a metal film 2, a self-assembled film 3, and a composite film 4 of metal oxide and polymer from bottom to top. The specific preparation steps of the sensor chip are as follows:

[0052] Step 1. Coating a metal film 2 with a thickness of 45 nm on the glass substrate 1 by vacuum evaporation;

[0053] Step 2. Place the glass substrate 1 after the vapor-deposited metal film 2 in mercaptoethylamine with a concentration of 0.1mmol / L. Rinse and dry with high-purity nitrogen to form a self-assembled film 3 on the metal film 2;

[0054] Step 3. Disperse the titanium dioxide powder into distilled water and ultrasonically mix to obtain a concentration of 1×10 -7 mol / L suspension solution;

[0055] Step 4. Mix 0.0086 g of methacrylic acid, 0.0344 g of ethylene glycol dimethacrylate, and 900 μL of acetonitrile solution containing 0.002 g of azobisisobutyronitrile, and ultrasonically degas for 10 minutes to obtain a mixed solution I; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com