Preparation and application of cobalt and nitrogen co-doped porous carbon microsphere material

A technology of co-doping and porous carbon, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor cycle stability, poor methanol tolerance, high price, and limited fuel cells, so as to facilitate material diffusion and electronic The effect of low transmission and preparation cost and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

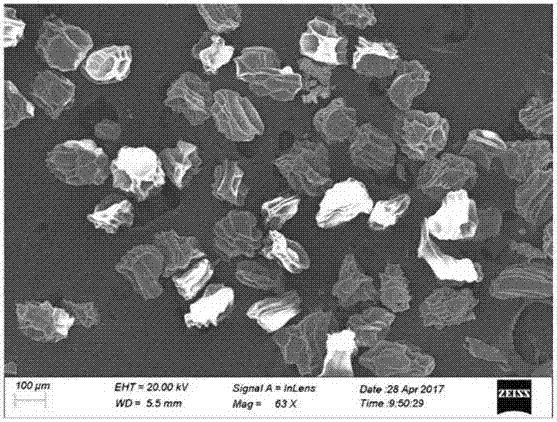

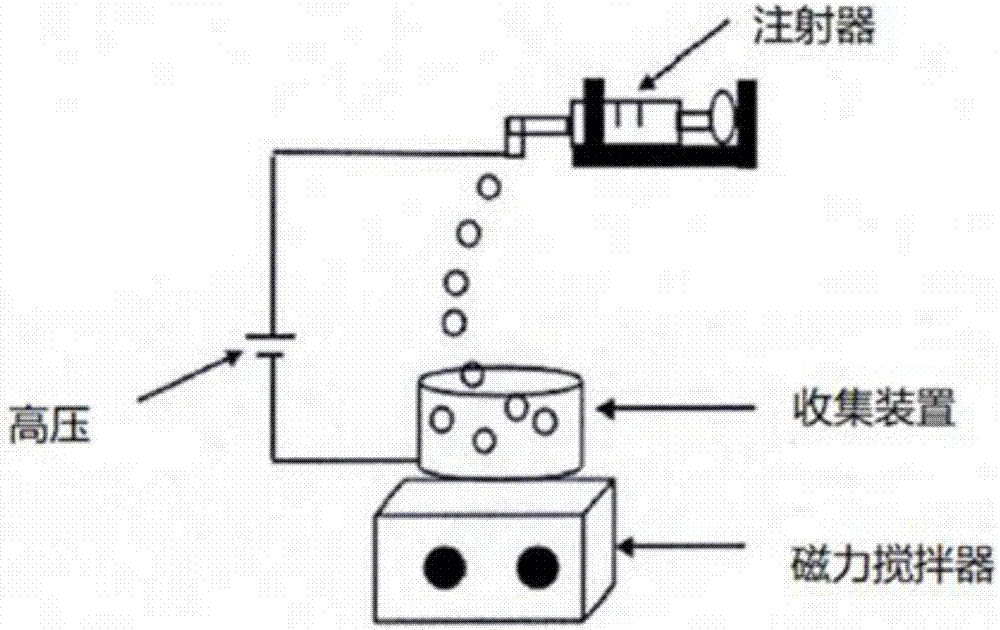

[0024] Prepare 1wt% sodium alginate aqueous solution, and add it into the syringe, use 3wt% cobalt nitrate aqueous solution as the receiving solution, in the environment where the output voltage of the high-voltage power supply is 25KV, the distance between the needle and the receiving device is 10cm, and the flow rate is 2mL / h The gel microspheres were obtained by electrospinning by electrospinning machine under the condition. After standing for 12 h, the microspheres were washed twice with absolute ethanol and deionized water, respectively. Put the above microspheres into a freeze dryer to freeze-dry to obtain cobalt alginate microspheres;

[0025] The above microspheres were placed in a 0.15 mol / L methanol solution of 2-methylimidazole and stirred at room temperature for 12 hours, washed several times with absolute ethanol and deionized water, and then freeze-dried to obtain cobalt alginate / ZIF-67 gas gel;

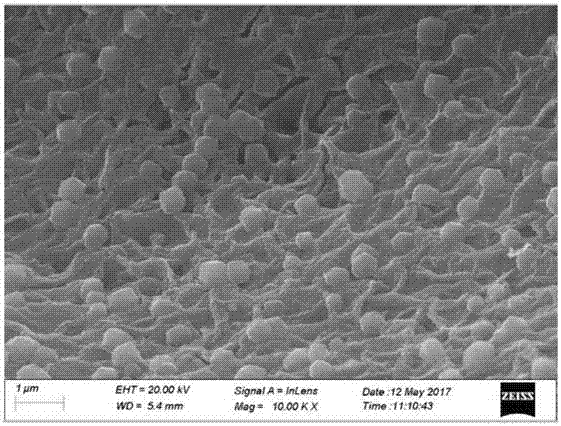

[0026] The cobalt alginate / ZIF-67 airgel was raised to 600°C at ...

Embodiment 2

[0028] Prepare 2wt% sodium alginate aqueous solution and add it into the syringe, use 6wt% cobalt nitrate aqueous solution as the receiving liquid, the output voltage of the high-voltage power supply is 15KV, the distance between the needle and the receiving device is 5cm, and the flow rate is 0.5mL / h Under certain conditions, electrospinning was used to electrospray to obtain gel microspheres. After standing for 12 h, the microspheres were washed twice with absolute ethanol and deionized water, respectively. Put the above microspheres into a freeze dryer to freeze-dry to obtain cobalt alginate microspheres;

[0029] The above microspheres were placed in a 0.3 mol / L methanol solution of 2-methylimidazole and stirred at room temperature for 12 hours, washed with absolute ethanol and deionized water for several times, and then freeze-dried to obtain cobalt alginate / ZIF-67 gas gel;

[0030] The cobalt alginate / ZIF-67 airgel was raised to 600°C at a heating rate of 5°C / min in a ...

Embodiment 3

[0032] Prepare 3wt% sodium alginate aqueous solution and add it into the syringe, use 9wt% cobalt nitrate aqueous solution as the receiving liquid, the output voltage of the high-voltage power supply is 30KV, the distance between the needle and the receiving device is 5cm, and the flow rate is 0.5mL / h Under certain conditions, electrospinning was used to electrospray to obtain gel microspheres. After standing for 12 h, the microspheres were washed twice with absolute ethanol and deionized water, respectively. Put the above microspheres into a freeze dryer to freeze-dry to obtain cobalt alginate microspheres;

[0033] The above microspheres were placed in 0.45 mol / L methanol solution of 2-methylimidazole and stirred at room temperature for 12 hours, washed with absolute ethanol and deionized water for several times, and then freeze-dried to obtain cobalt alginate / ZIF-67 gas gel;

[0034] The cobalt alginate / ZIF-67 airgel was raised to 600°C at a heating rate of 5°C / min in a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com