Process for preparing blonanserin

A preparation process, the technology of blonanserin, which is applied in the field of preparation process of antipsychotic drug blonanserin tablets, can solve the problems of easy adsorption on the container wall, uniform dissolution rate of tablets, obvious static electricity, etc., and achieve increased mixing Uniformity, increase fluidity, and eliminate static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

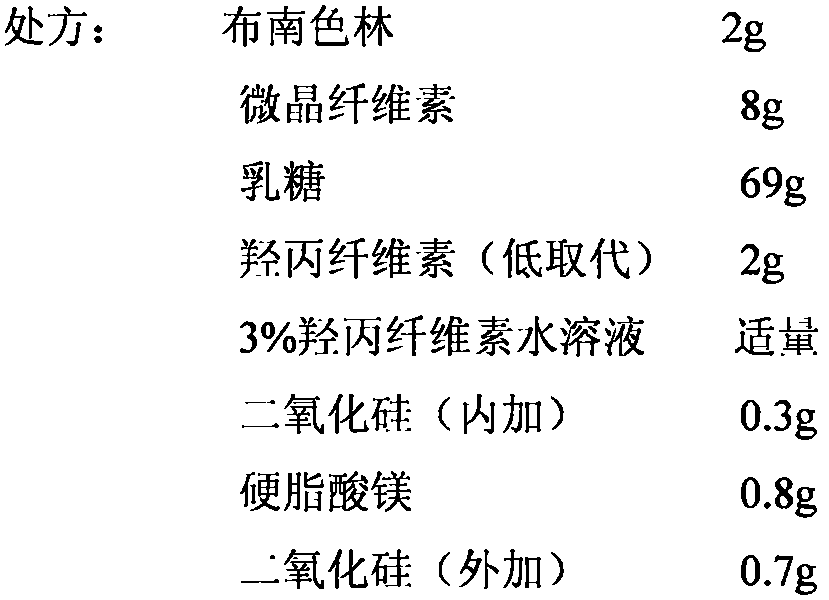

[0024]

[0025] Made into 1000 pieces

[0026] Preparation process: Mix micronized blonanserin and part of silicon dioxide and pass through a 60-mesh sieve to form a premix; add the premix, hydroxypropyl cellulose (low substitution) and lactose into a wet granulator and mix 5min; the mixture is made into a soft material with an appropriate amount of hydroxypropyl cellulose aqueous solution, and granulated through a 24-mesh sieve; the wet granules are air-dried at 50°C, passed through a 24-mesh sieve for granulation, and the remaining amount of silicon dioxide, microcrystalline cellulose and hard Magnesium fatty acid was mixed for 5 minutes and compressed into tablets.

Embodiment 2

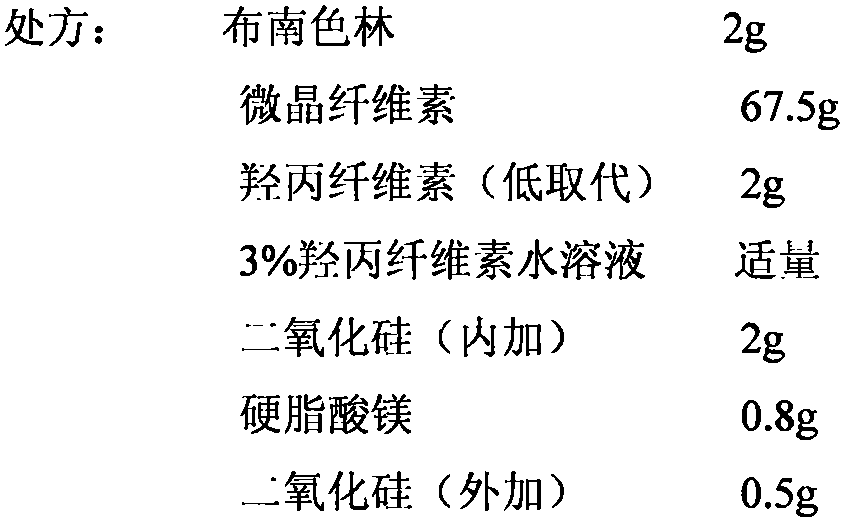

[0028]

[0029] Made into 1000 pieces

[0030] Preparation process: Mix micronized blonanserin and part of silicon dioxide and pass through a 60-mesh sieve to form a premix; add the premix, hydroxypropyl cellulose (low substitution) and lactose into a wet granulator and mix 15min; the mixture is made into a soft material with an appropriate amount of hydroxypropyl cellulose aqueous solution, and granulated through a 20-mesh sieve; the wet granules are air-dried at 60°C, granulated through a 20-mesh sieve, and the remaining amount of silicon dioxide, microcrystalline cellulose and hard Magnesium fatty acid was mixed for 15 minutes and compressed into tablets.

Embodiment 3

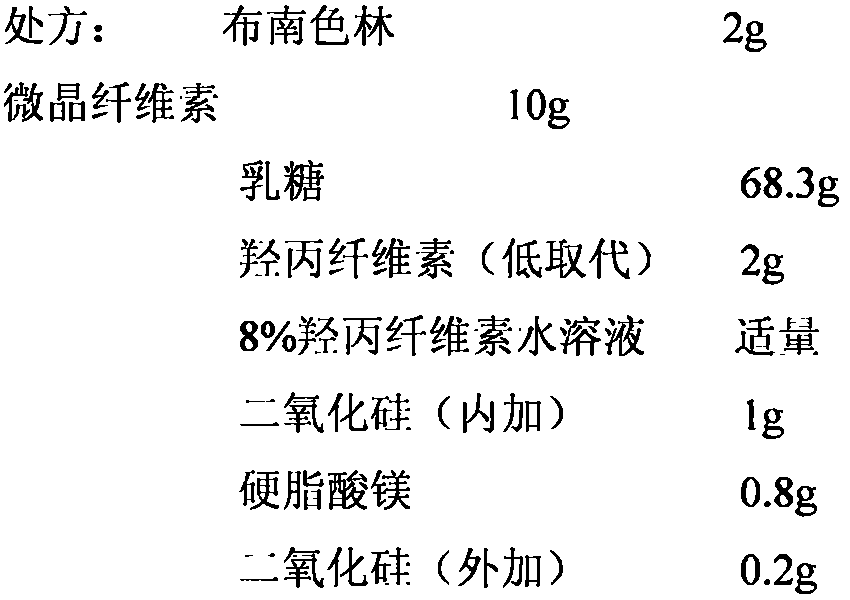

[0032]

[0033] Made into 1000 pieces

[0034] Preparation process: Mix micronized blonanserin and part of silicon dioxide and pass through a 60-mesh sieve to form a premix; add the premix, hydroxypropyl cellulose (low substitution) and lactose into a wet granulator and mix 20min; the mixture is made into a soft material with an appropriate amount of hydroxypropyl cellulose aqueous solution, and granulated through a 24-mesh sieve; the wet granules are air-dried at 80°C, granulated through a 24-mesh sieve, and the remaining amount of silicon dioxide, microcrystalline cellulose and hard Magnesium fatty acid was mixed for 15 minutes and compressed into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com