Antithrombotic metallic material

A metal material and anti-thrombosis technology, which is applied in the direction of anti-coagulation treatment, packaging item types, special packaging items, etc., can solve the problems of blood recognition as foreign matter and easy formation of thrombus, and achieve the effect of maintaining low hemolytic toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

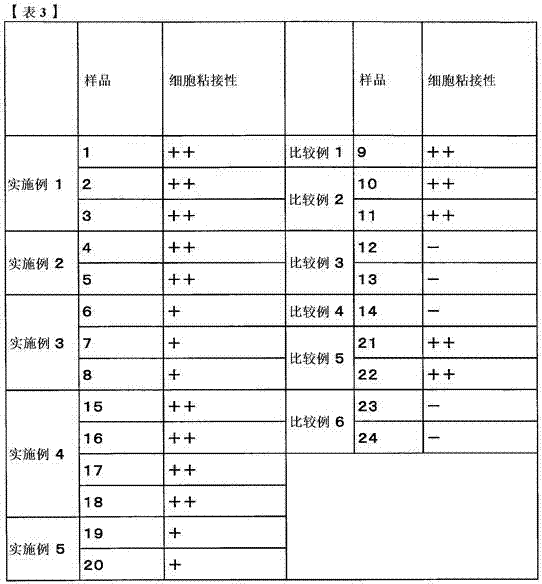

Examples

Embodiment 1)

[0157] As the metal material, a plate material of SUS304 (length: 1 cm, width 0.5 cm) was used. SUS304 was ultrasonically washed with water, acetone, and methanol in sequence, and then vacuum-dried. The washed SUS304 was immersed in 1 mM compound A (the following general formula (I)) ethanol solution at 37°C overnight, then washed with ethanol and water, and then vacuum-dried to covalently bond compound A to SUS304. surface (1st coating process).

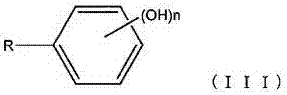

[0158] [chemical formula 9]

[0159]

[0160] Next, SUS304 was immersed in an aqueous solution of 0.5% by weight of DMT-MM (manufactured by Wako Pure Chemical Industries, Ltd.) and 5.0% by weight of PEI (LUPASOL (registered trademark) P; manufactured by BASF Corporation) as a part of the coating material. Reaction was performed at 30° C. for 2 hours, and PEI was covalently bonded to compound A by condensation reaction (second coating step). The aqueous solution after the reaction was removed and washed with distilled water.

...

Embodiment 2)

[0166] Except changing compound A to compound B (the following general formula (II)), the same operation as Example 1 was performed, and the 1st coating process and the 2nd coating process were implemented. In addition, the same operation as in Example 1 was performed, and after the quaternization step was implemented using ethyl bromide, the third coating step was implemented.

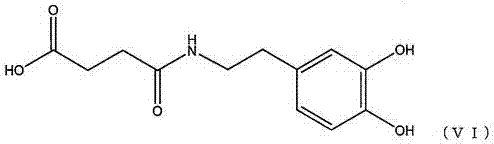

[0167] [chemical formula 10]

[0168]

[0169] Here, SUS304 subjected to the second coating process with PEI (LUPASOL (registered trademark) P; manufactured by BASF Corporation) was used as sample 4, and PEI (average molecular weight about 70,000; manufactured by Wako Pure Chemical Industries, Ltd.) was subjected to the second coating step. The SUS304 of the 2-coating process was set as sample 5.

[0170] For each sample, the ratio of the amount of nitrogen atoms and sulfur atoms on the surface measured by X-ray photoelectron spectroscopy (XPS) to the amount of all atoms, and the anti-Xa Determin...

Embodiment 3)

[0172] The same operation as in Example 1 was carried out, and after the first coating step and the second coating step were implemented, SUS304 was immersed in an aqueous solution of 0.5% by weight DMT-MM and 0.5% by weight PAA (manufactured by Wako Pure Chemical Industries, Ltd.). Reaction was performed at 30° C. for 2 hours (first additional step). The aqueous solution after the reaction was removed, and washed with an aqueous sodium carbonate solution and distilled water.

[0173] Furthermore, SUS304 was immersed in the aqueous solution of 0.5weight% DMT-MM and 5.0weight%PEI, and it reacted at 30 degreeC for 2 hours (2nd additional process). The aqueous solution after the reaction was removed and washed with distilled water. The same operation as in Example 1 was performed, and after the quaternization step was implemented using ethyl bromide, the third coating step was implemented.

[0174] Here, SUS304 subjected to the first coating process with compound A and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com