Agglomerated high-hydrophilic strong anion exchanger, preparation method and application of anion exchanger in liquid chromatographic column filler

A technology of strong anion and exchanger, applied in the preparation, application of liquid chromatography column packing, agglomerated highly hydrophilic strong anion exchanger, can solve the problem of non-agglomeration of nanoparticles, difficulty in applying strong hydrophobicity, Difficult to agglomerate nanoparticles uniformly and other problems, so as to avoid the use of highly toxic reagents, the operation process is green and environmentally friendly, and the effect of overcoming uneven agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] 1) Preparation of polymer microspheres;

[0037] A suspension polymerization method is used to prepare polymer microspheres, and the polymer microspheres are chloromethylstyrene and divinylbenzene copolymer-based balls;

[0038] 2) Sulfonation of polymer microspheres;

[0039] Under the condition of an ice-water bath, disperse the chloromethylstyrene and divinylbenzene copolymer-based balls prepared in step 1) in a sulfuric acid solution; then continuously stir the reaction at room temperature to obtain a suspension, and the suspension Pour into the ice-water bath solution to terminate the reaction, and after suction filtration, wash the filter cake to neutrality to obtain sulfonated polymer microspheres;

[0040] 3) Preparation of quaternized polyvinyl alcohol;

[0041] Disperse polyvinyl alcohol in water, add sodium hydroxide and 3-chloro-2-hydroxypropyltrimethylammonium chloride at a temperature of 80-95°C, react continuously under the condition of magnetic stirrin...

Embodiment 1

[0045] 1) Preparation of polymer microspheres: Copolymer-based spheres of chloromethylstyrene and divinylbenzene with a particle size of about 8 μm were prepared by suspension polymerization.

[0046] 2) Sulfonation of polymer microspheres: Weigh 10 g of the prepared chloromethylstyrene and divinylbenzene copolymer-based balls and place them in a 50 mL round-bottomed flask. Add 20 mL of sulfuric acid solution with a mass percent content of 60%, and make the chloromethylstyrene and divinylbenzene copolymer-based balls completely dispersed in the sulfuric acid solution by magnetic stirring, and continuously stir for 30min at room temperature 30°C Finally, a suspension is obtained, which is poured into an ice-water bath solution to terminate the reaction, and the above-mentioned ice-water bath solution is suction-filtered, and the obtained filter cake is washed to neutrality to obtain the required sulfonated polymer microspheres.

[0047] 3) Quaternization of polyvinyl alcohol: T...

Embodiment 2

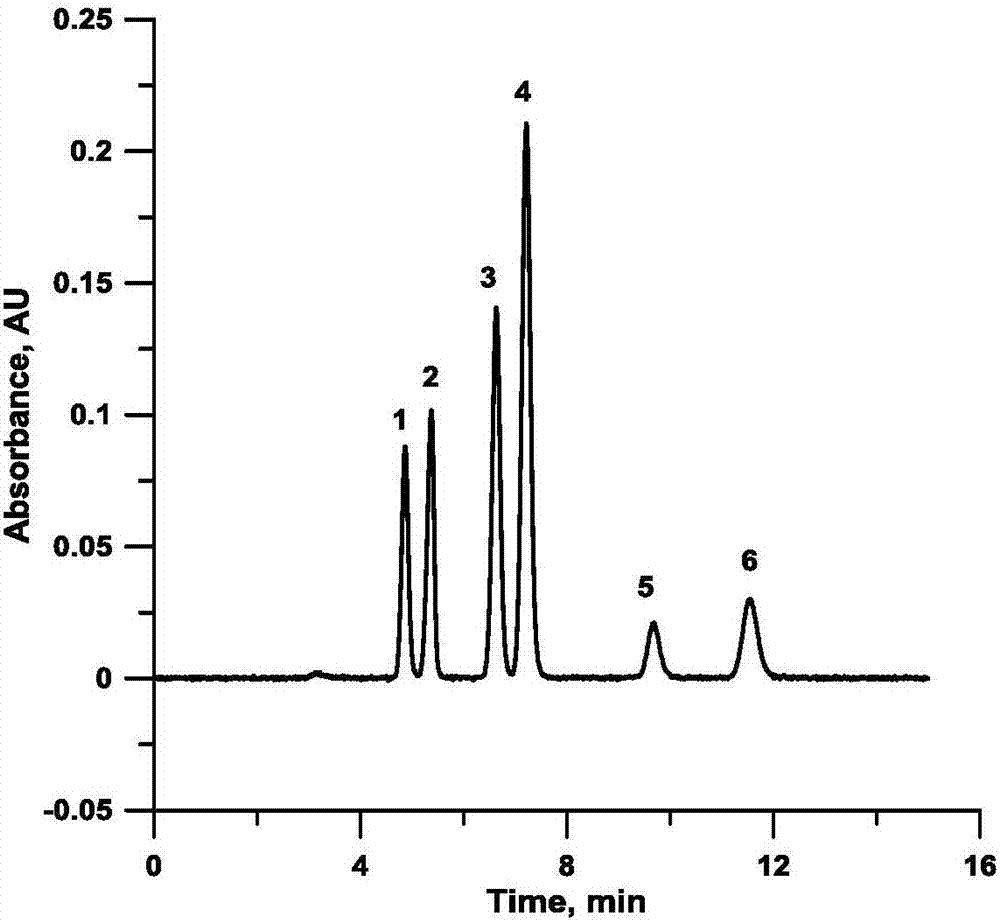

[0050] The highly hydrophilic strong anion exchanger obtained by agglomerating sulfonated polymer-based balls with quaternized polyvinyl alcohol is dispersed in the homogenate, and loaded into a chromatographic column under a hydraulic pressure of 5000 psi. The flow rate is 1mL / min, the mobile phase is 5mM potassium carbonate, and the IO is separated under the ultraviolet detection mode. 3 - , BrO 3 - , NO 2 - , NO 3 - , I - and SCN - ions, see the attached spectrum figure 1 . Obviously, the anion exchange chromatographic filler obtained by adopting the quaternized polyvinyl alcohol agglomerated sulfonated polymer microspheres proposed by the present invention in this example shows good separation performance for the above-mentioned ions.

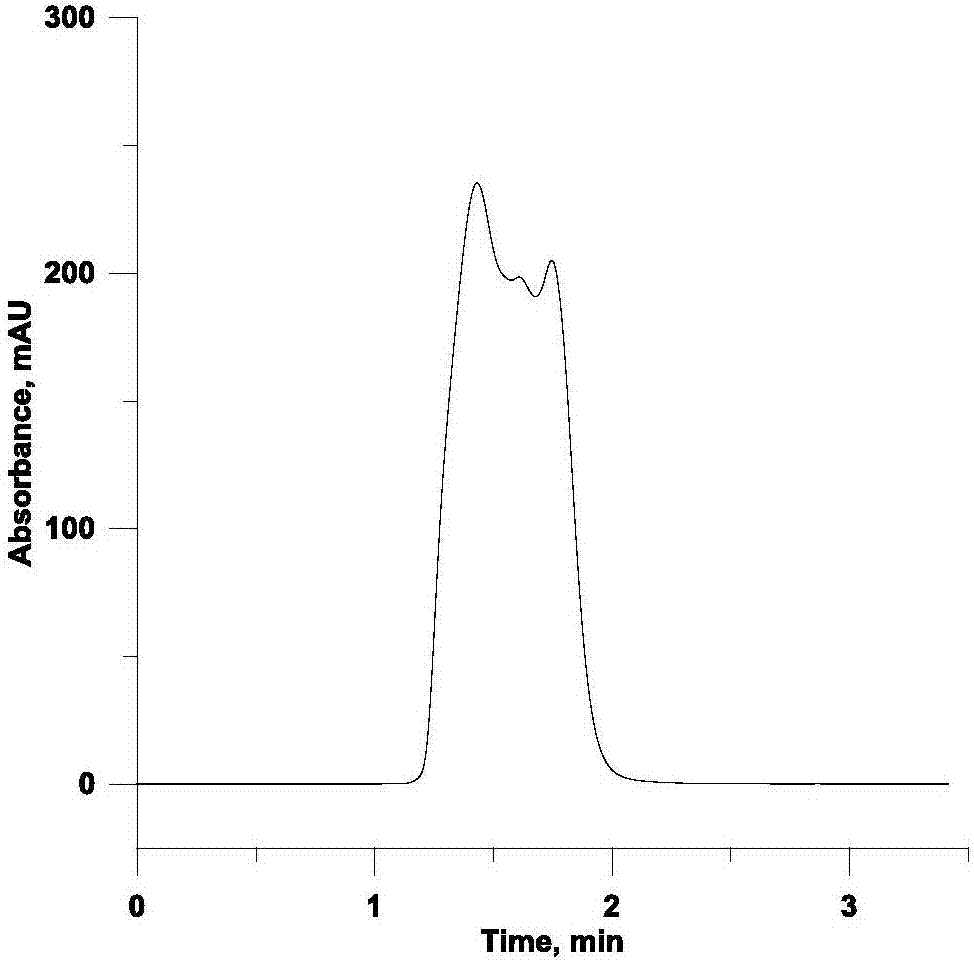

[0051] Comparative test: In order to further highlight the separation effect of the chromatographic filler of the present invention, the method mentioned in the Chinese invention patent CN104226283 B, that is, the use of polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com