Resin-method recovering technology for electroplating waste acid and diluted acid waste water

A technology for waste acid water and resin, which is applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment and other directions, can solve the problems of high loss rate of main components, difficult operation, low recovery efficiency, etc. The effect of simple process and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The first step, filter

[0042] The raw material of this example uses electroplating sulfuric acid wastewater with a mass fraction of 20%, wherein the main impurity aluminum ion concentration is 10-15g / L, and filter paper is used to filter the solid particles in the feed solution.

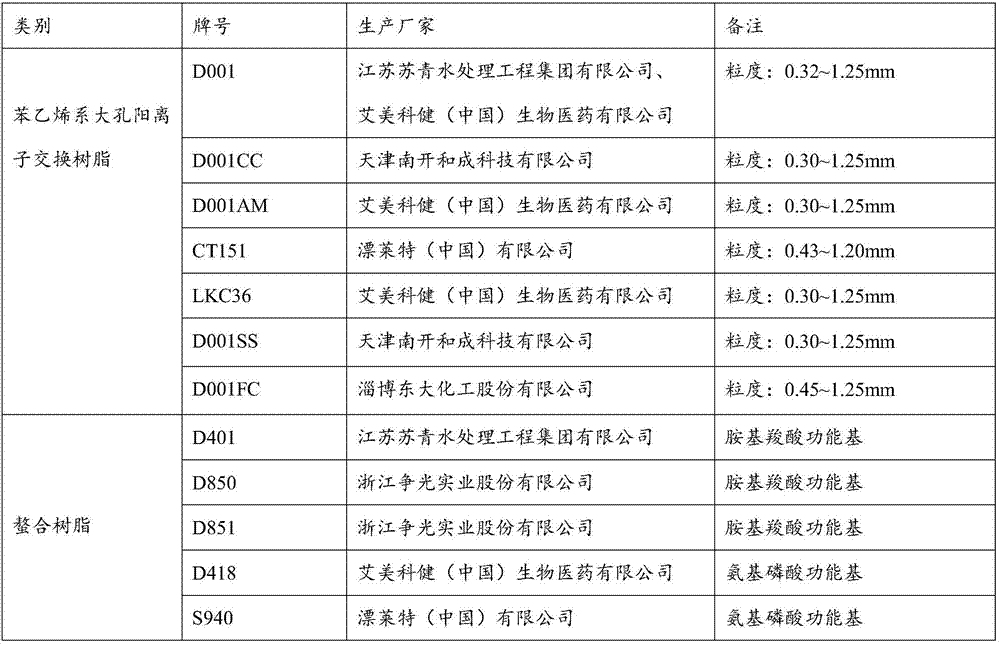

[0043] The second step, mixed resin to remove metal ions in waste acid water

[0044] (1) Pretreatment of resin

[0045]Mix 90mL of D001SC resin with 10mL of D418 resin and put it into an ordinary glass chromatography column, keeping the aspect ratio of the resin in the chromatography column at (1~7):1. According to the national standard GB / T 5476-2013 and the hydrochloric acid solution used in the national standard GB / T 5476-2013 is replaced by a sulfuric acid solution with a mass fraction of 2.5% to pretreat the mixed resin in the exchange column. That is: use 1mol / L NaOH aqueous solution 5BV (resin column volume) to pass through the resin at a flow rate of 2-5BV / h, wash with 5-15BV deio...

Embodiment 2

[0052] The first step, filter

[0053] In Example 2, use the by-product waste acid water in the sulfuric acid production process—the dilute sulfuric acid waste liquid (waste acid water) with a mass fraction of about 18%, wherein the main impurity aluminum ion concentration is 10~15g / L, use filter paper to filter the waste acid Solid impurities in water.

[0054] The second step, mixed resin to remove metal ions

[0055] (1) Pretreatment of resin

[0056] Mix 85mL of D001AM resin with 15mL of S940 resin and put it into an ordinary glass chromatography column, keeping the height-to-diameter ratio of the resin in the chromatography column at (1-7):1. According to the national standard GB / T 5476-2013 and the hydrochloric acid solution used in the national standard GB / T 5476-2013 is replaced by a sulfuric acid solution with a mass fraction of 2.5% to pretreat the mixed resin in the exchange column. That is: use 5BV of 1mol / L NaOH aqueous solution to pass through the resin at a f...

Embodiment 3

[0063] The first step, filter

[0064] In Example 3, dilute sulfuric acid with a by-product mass fraction of about 20% in the sulfuric acid production process was used for waste acid water, and the impurity aluminum ion concentration was 15g / L, and filter paper was used to filter solid impurities in the feed liquid.

[0065] The second step is to mix the resin to remove metal ions;

[0066] (1) Pretreatment of resin

[0067] Mix 85mL of D001SC resin with 15mL of D401 resin and put it into an ordinary glass chromatography column, keeping the aspect ratio of the resin in the chromatography column at (1-7):1. According to the national standard GB / T 5476-2013 and the hydrochloric acid solution used in the national standard GB / T 5476-2013 is replaced by a sulfuric acid solution with a mass fraction of 2.5% to pretreat the mixed resin in the exchange column. That is: use 5BV of 1mol / L NaOH aqueous solution to pass through the resin at a flow rate of 2 to 5BV / h, wash with 5 to 15BV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com