Straw composite organic fertilizer and preparation method thereof

A technology of organic fertilizer and straw, which is applied in the field of straw compound organic fertilizer and its preparation, can solve problems affecting crop yield and achieve the effect of ensuring healthy growth and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of straw compound organic fertilizer, comprising the following steps:

[0035] a) Mix the straw, bean curd residue, phosphate rock powder, trace elements, compound microbial agent, and appropriate amount of water evenly, seal and ferment at room temperature for 10 to 15 days, and turn the pile once every 3 to 4 days to obtain the fermented liquid;

[0036] b) Add mint powder, lycorine, pomegranate peel powder, distiller's grains, humic acid, potassium sodium tartrate, and activated carbon to the fermented liquid obtained in step a), stir evenly, dry, grind into powder, and obtain straw compound organic fertilizer .

[0037] The above-mentioned straw, bean curd residue, phosphate rock powder, trace elements, compound microbial agent, mint powder, lycorine, pomegranate peel powder, distiller's grains, humic acid, potassium sodium tartrate, and activated carbon are all the same as above, and will not be repeated here...

Embodiment 1

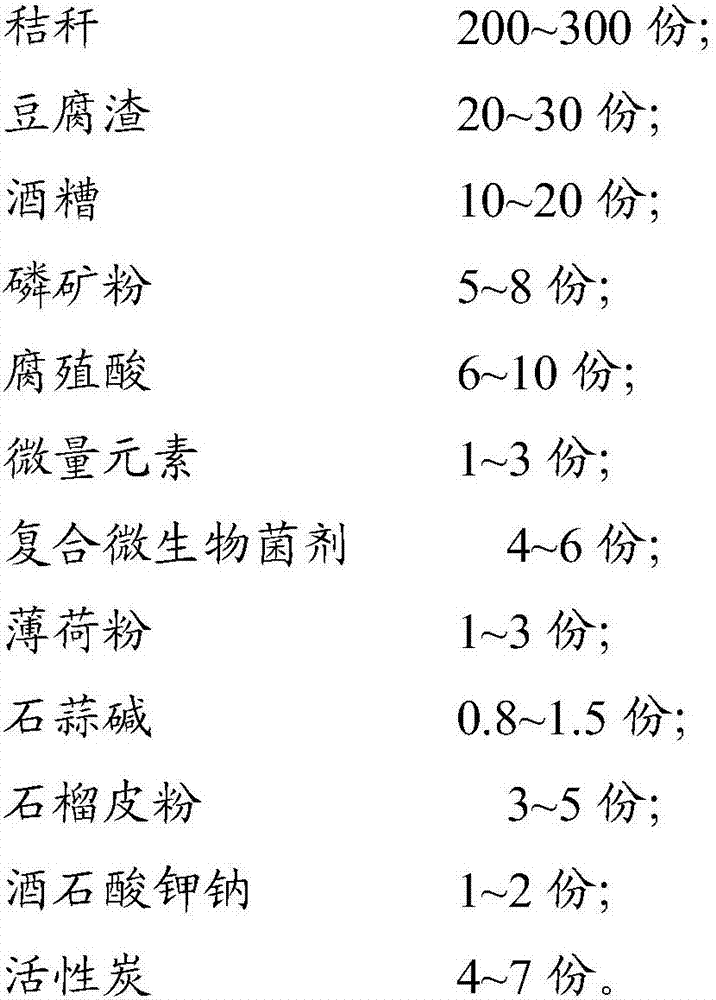

[0042] The straw compound organic fertilizer includes the following raw materials in parts by weight:

[0043]235 parts of straw, 24 parts of bean curd residue, 16 parts of distiller's grains, 6 parts of phosphate rock powder, 7.6 parts of humic acid, 0.22 parts of zinc chloride, 0.11 parts of copper sulfate, 0.1 part of sodium manganate, 0.19 parts of boric acid, 0.37 parts of sulfurous acid Iron, 0.004 parts of sodium molybdate, 0.35 parts of Bacillus subtilis, 0.52 parts of potassium solubilizing bacteria, 2.61 parts of yeast, 1.04 parts of nitrogen-fixing bacteria, 0.17 parts of phosphorus bacteria, 1.6 parts of mint powder, 1.1 parts of lycorine, 3.7 parts of pomegranate peel powder, 1.4 parts of potassium sodium tartrate, 4.8 parts of activated carbon;

[0044] The preparation method of straw compound organic fertilizer comprises the following steps:

[0045] a) Straw, bean curd residue, phosphate rock powder, zinc chloride, copper sulfate, sodium manganate, boric acid,...

Embodiment 2

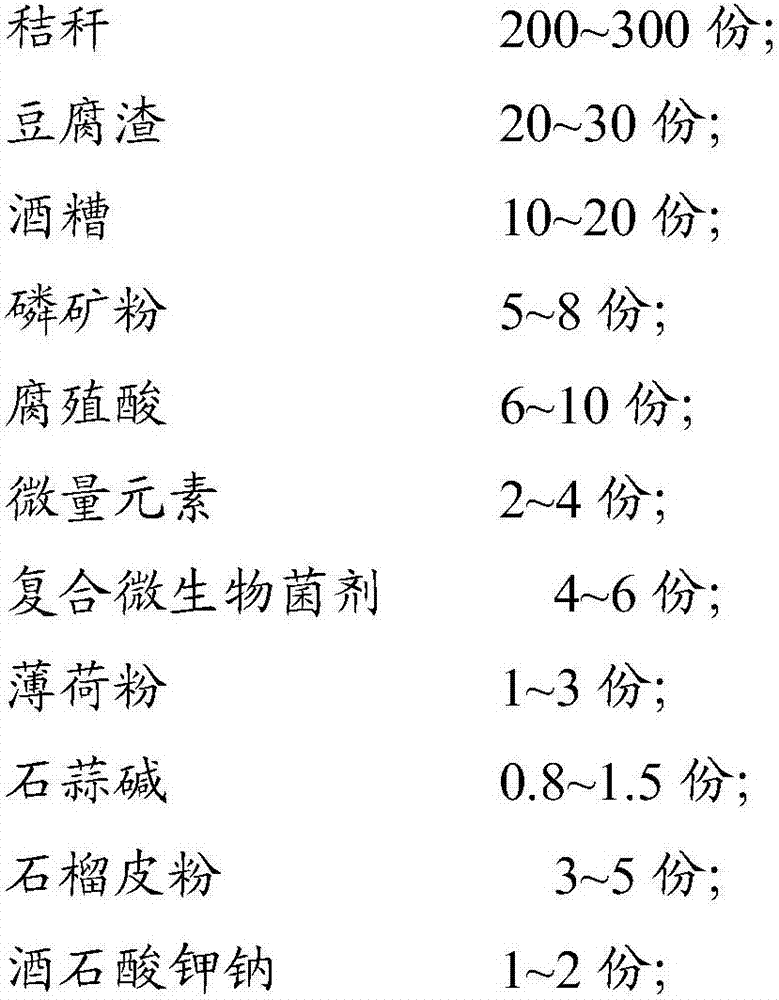

[0048] The straw compound organic fertilizer includes the following raw materials in parts by weight:

[0049] 260 parts of straw, 22 parts of bean curd residue, 18 parts of distiller's grains, 5.5 parts of phosphate rock powder, 7 parts of humic acid, 0.22 parts of zinc chloride, 0.11 parts of copper sulfate, 0.1 part of sodium manganate, 0.19 parts of boric acid, 0.37 parts of sulfurous acid Iron, 0.004 parts of sodium molybdate, 0.36 parts of Bacillus subtilis, 0.46 parts of potassium solubilizing bacteria, 2.33 parts of yeast, 1.17 parts of nitrogen-fixing bacteria, 0.18 parts of phosphorus bacteria, 1.2 parts of mint powder, 1 part of lycorine, 3.6 parts of pomegranate peel Powder, 1.3 parts potassium sodium tartrate, 4 parts activated carbon;

[0050] The preparation method of straw compound organic fertilizer comprises the following steps:

[0051] a) Straw, bean curd residue, phosphate rock powder, zinc nitrate, copper chloride, potassium manganate, borax, ferrous chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com