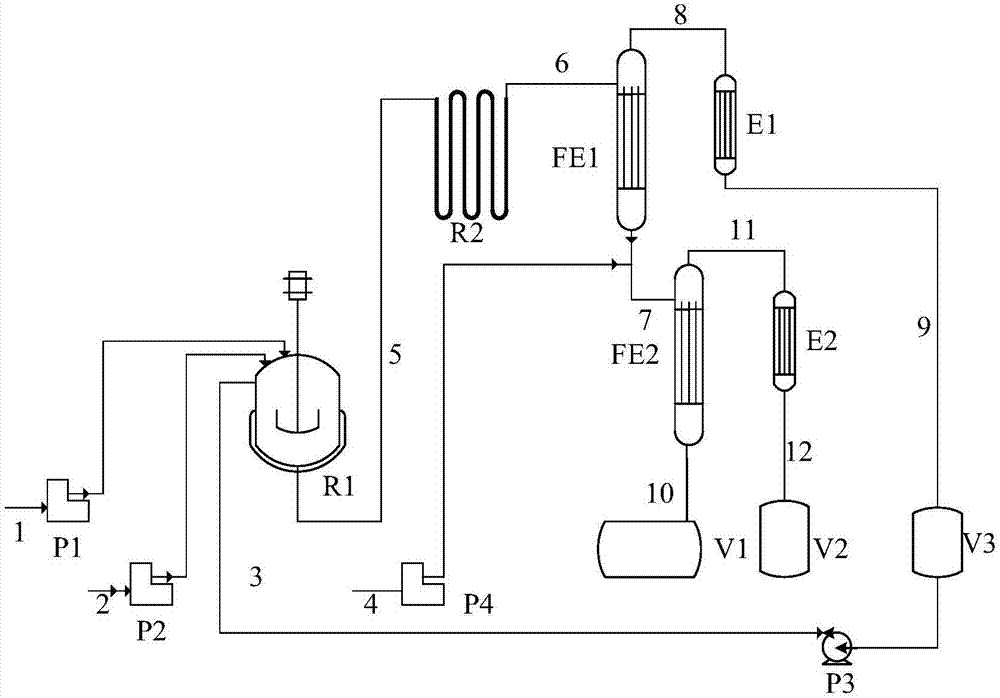

Method for synthesizing tetramethyl ammonium bicarbonate through tank reactor in serial connection with tubular reactor

The technology of a kettle-type reactor and a tubular reactor is applied in the field of synthesizing tetramethylammonium bicarbonate, which can solve the problems of complex design of the reactor heat exchange device, difficulty in smoothly removing the reaction heat, and large area of the reactor, etc. Save steam consumption, save equipment investment, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

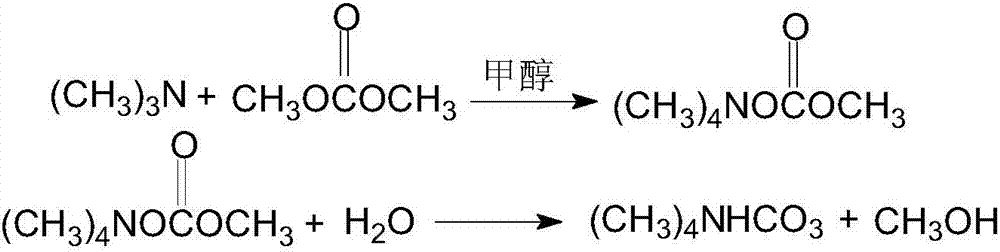

Method used

Image

Examples

Embodiment 1

[0032] According to the synthesis flow chart shown in the accompanying drawing, the various raw materials are put into the tank reactor according to the ratio of DMC:TMA:MEOH=1:0.9:2, and the reaction temperature of the tank reactor is controlled at 100°C. The reaction pressure of the reactor is 0.5MPa, the residence time of the material in the tank reactor is 60min, the reaction temperature of the tubular reactor is controlled at 140°C, the residence time of the material in the tubular reactor is 30min, and the first falling film evaporation The pressure of the device is 0.15MPa, and the evaporation temperature is 110°C. The pressure of the second falling film evaporator is normal pressure, and the evaporation temperature is 120°C. Sampling and analysis of the content of the product tetramethylammonium bicarbonate results in a yield of tetramethylammonium bicarbonate. was 85.3%.

Embodiment 2

[0034] According to the synthesis flow chart shown in the accompanying drawing, the various raw materials are put into the tank reactor according to the ratio of DMC:TMA:MEOH=1:1.1:5, and the reaction temperature of the tank reactor is controlled at 130°C. The reaction pressure of the reactor is 0.9MPa, the residence time of the material in the tank reactor is 30min, the reaction temperature of the tubular reactor is controlled at 110°C, the residence time of the material in the tubular reactor is 30min, and the first falling film evaporation The pressure of device is 0.20MPa, and evaporating temperature is 120 ℃, and the pressure of the second falling film evaporator is normal pressure, and evaporating temperature is 105 ℃, and the content of sampling analysis product tetramethylammonium bicarbonate gets tetramethylammonium bicarbonate yield was 96.8%.

Embodiment 3

[0036] According to the synthesis flow chart shown in the accompanying drawing, the various raw materials are put into the tank reactor according to the ratio of DMC:TMA:MEOH=1:1:3, and the reaction temperature of the tank reactor is controlled at 120°C. The reaction pressure of the reactor is 0.7MPa, the residence time of the material in the tank reactor is 50min, the reaction temperature of the tubular reactor is controlled at 120°C, the residence time of the material in the tubular reactor is 20min, and the first falling film evaporation The pressure of the device is 0.15MPa, and the evaporation temperature is 120°C. The pressure of the second falling film evaporator is normal pressure, and the evaporation temperature is 110°C. Sampling and analysis of the content of tetramethylammonium bicarbonate in the product results in a yield of tetramethylammonium bicarbonate. was 94.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com