Piperonal preparation method

A technology of jasmonal and catalyst, which is applied in the field of jasmonal preparation, can solve the problems of cumbersome treatment, high toxicity of chlorine gas, and many waste materials, and achieve the effects of simple process, low production cost and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

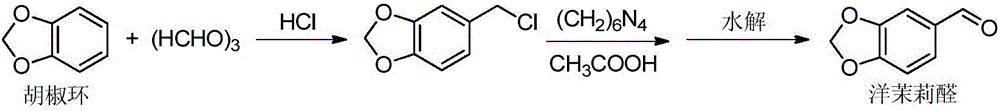

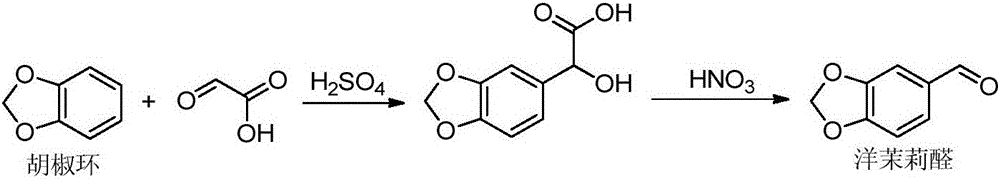

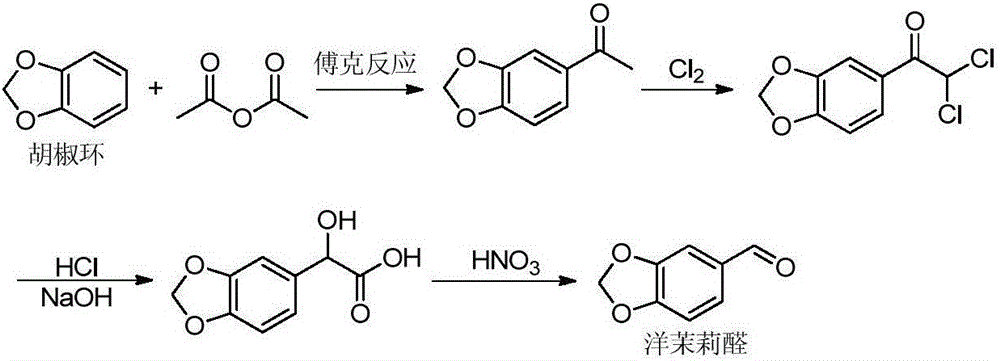

Method used

Image

Examples

Embodiment 1

[0032] In a 1L three-neck flask, add 500mL of dichloromethane, aluminum chloride / polystyrene (66.5g, loading capacity 10wt%), and slowly add acetyl chloride (42.9g, 5.5mol) dropwise under stirring conditions, and the dropwise addition is completed , then slowly drop piperonyl ring (61.0g, 0.5mol, dissolved in 100mL dichloromethane); Polystyrene catalyst; the reaction solution was extracted in layers, the organic layers were combined, the solvent was evaporated under reduced pressure, and the product was dried to obtain 77.2g, with a yield of 94%.

Embodiment 2

[0034] In a 1L three-necked flask, add 500mL of trifluoromethylbenzene, zinc chloride / aluminum trioxide (272.6g, loading capacity 10wt%), and slowly add acetic anhydride (56.1g, 0.55mol) dropwise under stirring conditions, drop After the addition is complete, slowly add piperonyl ring (61.0g, 0.5mol, dissolved in 100mL trifluoromethylbenzene); Zinc chloride / alumina catalyst; the reaction solution was extracted in layers, the organic layers were combined, the solvent was evaporated under reduced pressure, and the product was dried to obtain 73.9 g, with a yield of 90%.

Embodiment 3

[0036] In a 1L three-necked flask, add nitrobenzene 500mL, aluminum chloride / silicon dioxide (166.3g, loading capacity 10wt%), and slowly add acetic acid (33.0g, 0.55mol) dropwise under stirring condition, the dropwise addition is completed, Slowly add piperonyl ring (61.0g, 0.5mol, dissolved in 100mL nitrobenzene); Silicon oxide catalyst; the reaction solution was extracted in layers, the organic layers were combined, the solvent was evaporated under reduced pressure, and the product was dried to obtain 78.8g, with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com